Accelerated degradation test based method and system for rapid prediction of PCB insulation life

An accelerated degradation test, insulation life technology, applied in printed circuit testing, electronic circuit testing, etc., can solve a large number of problems, reliability evaluation, and improve forecast costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

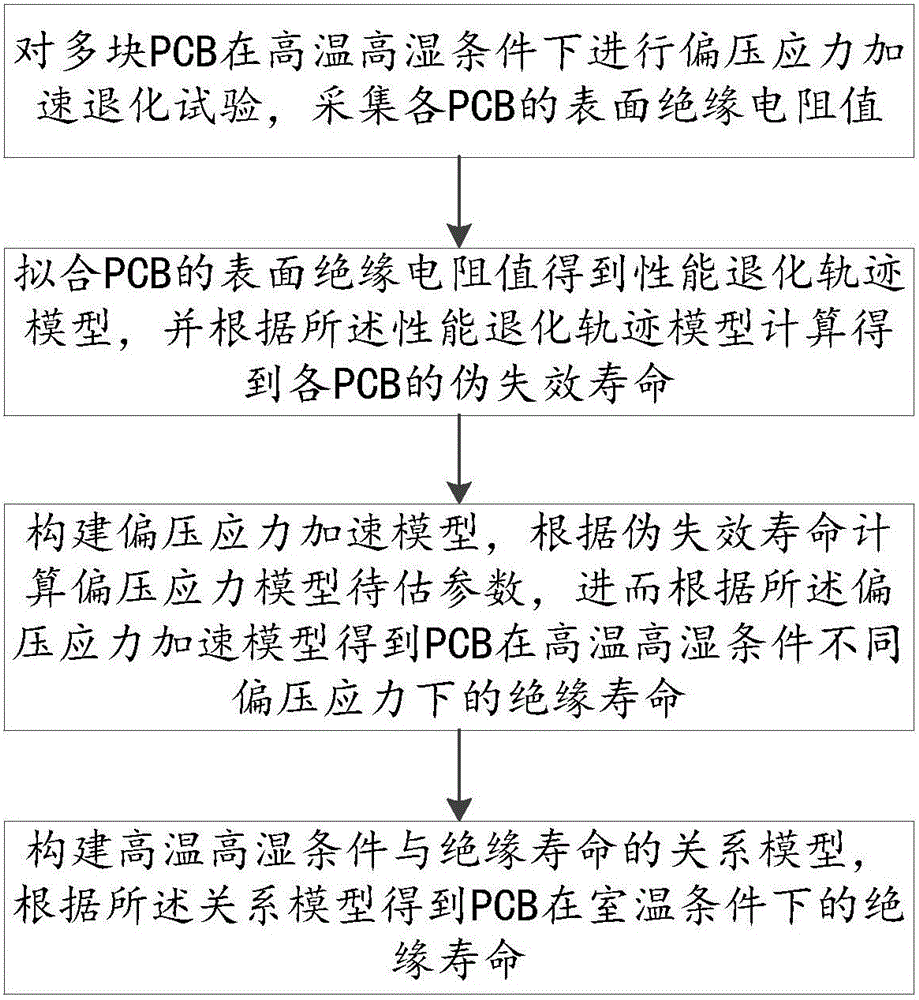

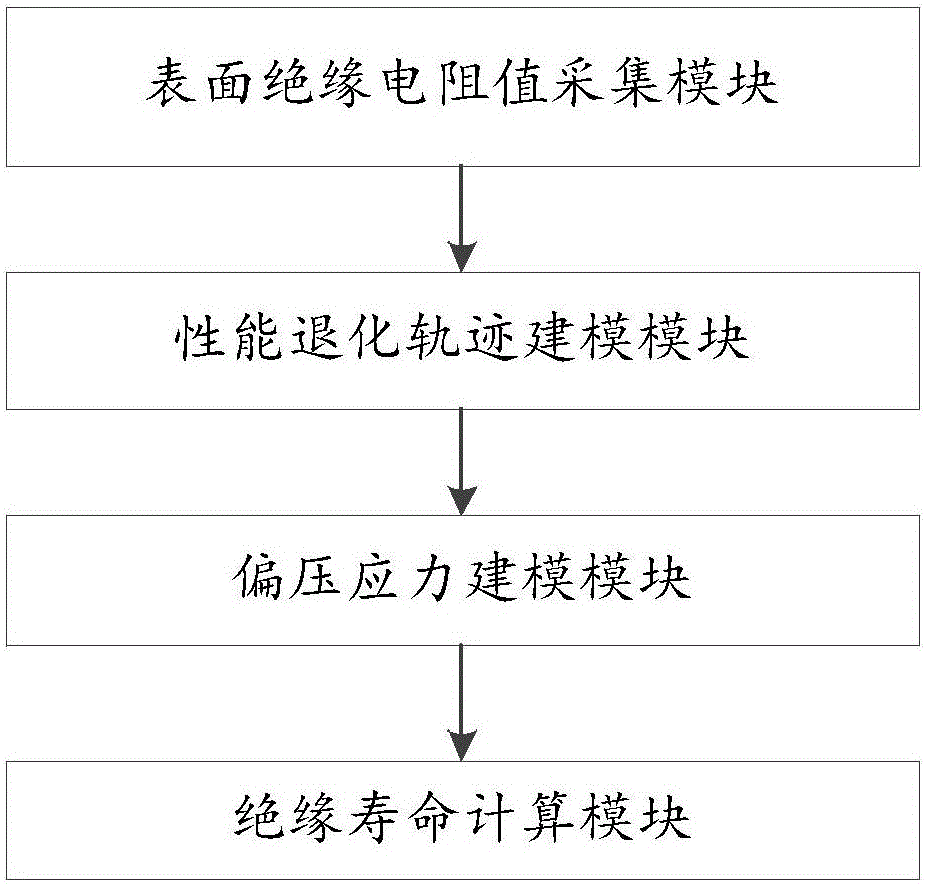

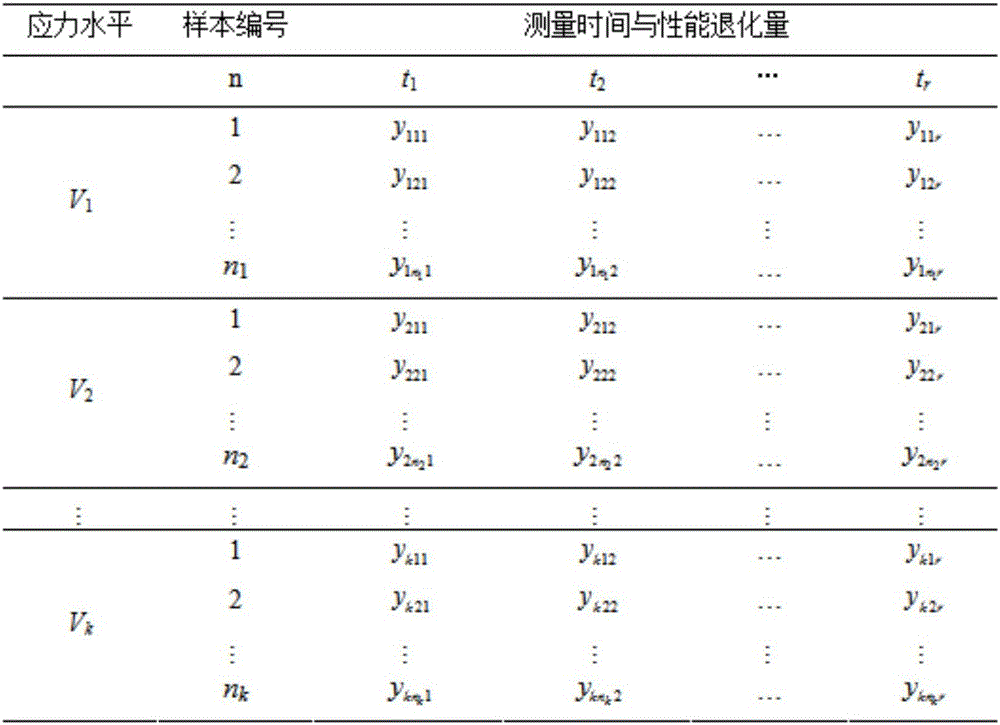

Method used

Image

Examples

Embodiment Construction

[0072] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0073] The following are explanations of terms involved in the present invention and test preconditions.

[0074] Performance degradation refers to a complex physical / chemical process in which the performance of a product changes regularly over time under the combined effects of its internal mechanism and the external environment. When this change reaches the failure threshold, it will cause the product to fail. For some long-life products whose performance degradation process is very slow, the accelerated degradation test method is generally used to obtain performance degradation data. That is, increasing certain stress levels on the premise of ensuring that the failure mechanism of the product remains unchanged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com