A high and low temperature control system for gas chromatographic separation

A gas chromatographic separation and control system technology, applied in the field of high and low temperature control systems, can solve problems such as unfavorable chromatographic column pretreatment activation, large loss of liquid nitrogen, inconvenient maintenance, etc., and achieves good applicability, effective temperature adjustment, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

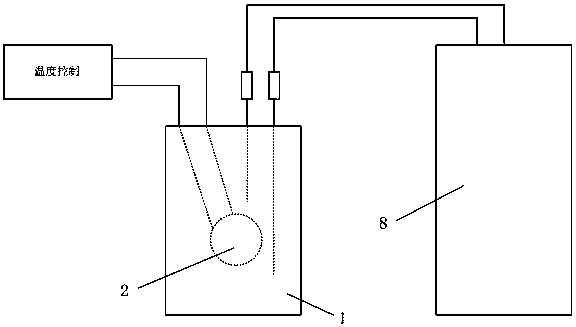

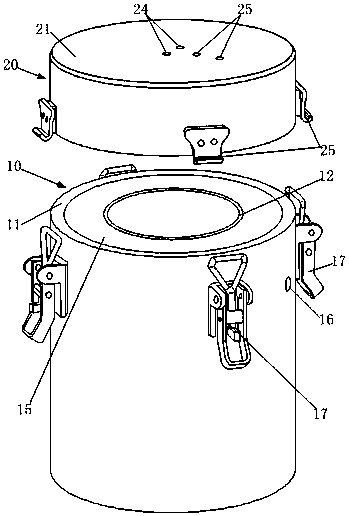

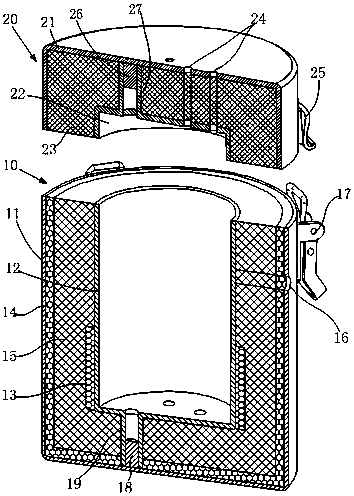

[0029] Such as Figure 1 to Figure 5 As shown, the high and low temperature control system for gas chromatographic separation includes a high and low temperature column box 1, a chromatographic column 2 placed in the high and low temperature column box, and a chromatographic valve 3 connected to the chromatographic column through the first chromatographic gas pipeline 4 , the chromatographic detector 5 connected to the chromatographic column through the second chromatographic gas pipeline 6, the self-pressurized liquid nitrogen tank 8 that is connected to the high and low temperature column box through a pair of liquid nitrogen transfer pipes 7 to form a liquid nitrogen circulation loop, and is arranged in the liquid The low temperature electromagnetic valve 9 on the nitrogen transfer pipe, and the external temperature control device arranged outside the high and low temperature column oven.

[0030] Further, the high and low temperature column box includes a box body 10 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com