Method for determining contents of silicon dioxide, aluminum sesquioxide and magnesium oxide in carbide slag

A technology of aluminum oxide and silicon dioxide, applied in material excitation analysis, thermal excitation analysis and other directions, can solve the problems of slow detection speed, pollute the environment, waste manpower and other problems, achieve low detection limit, low spectral interference, and method quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

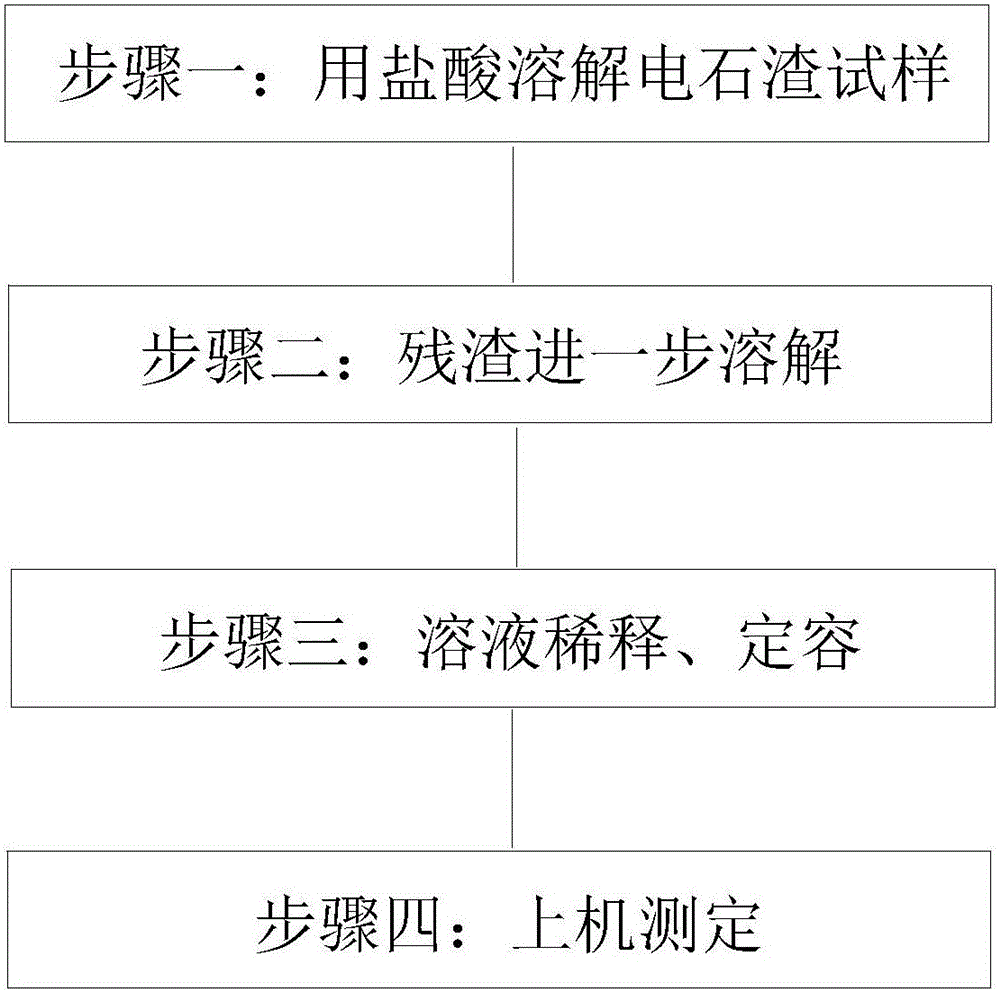

[0024] The method steps of this specific embodiment are as figure 1 As shown, the main method flow is: dissolve most of the samples with hydrochloric acid (1+1), filter the solution, wash the residue, transfer the solution to a 250mL volumetric flask, dilute to the mark with water, and shake well. The plasma spectrometer is used for measurement, and the content of the analytical elements in the sample is obtained according to the calibration curve prepared by the standard solution.

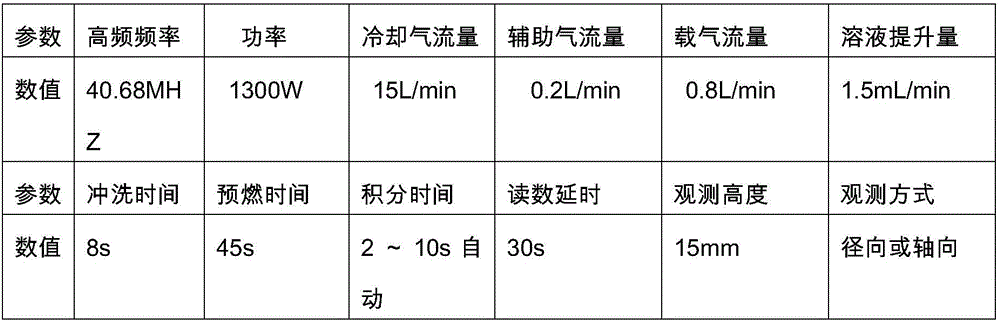

[0025] Main instruments and working parameters:

[0026] ICP-OES: Produced by PE Company in the United States, OPTIMA5300DV two-way observation type full-spectrum direct-reading plasma spectrometer, solid-state detector (CCD), wavelength range 190-780nm, echelle grating, gem cross nebulizer, SCOTTON fog chamber, high The swirling spray chamber was used for the concentration, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com