Density measurement equipment and method for variable-temperature metal

A technology of metal density and measuring equipment, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of lack of fast and accurate measurement methods, and achieve the effect of wide range of applicable objects, wide temperature range and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

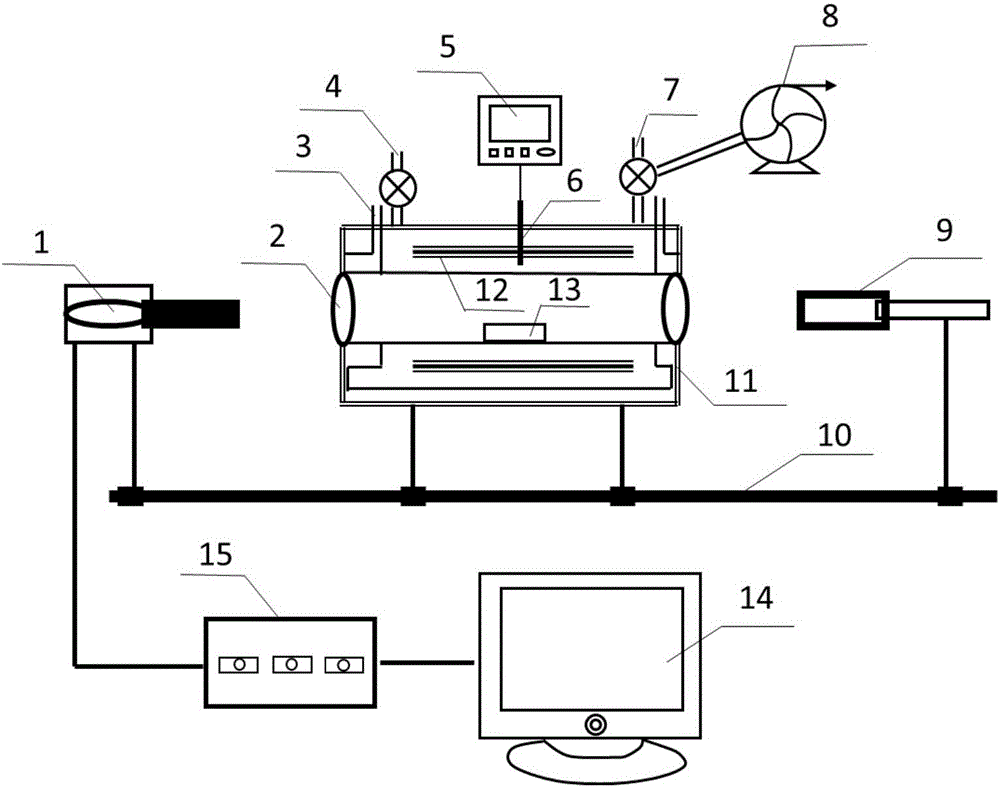

Method used

Image

Examples

Embodiment 1

[0032] Sample Sb of the present invention 2 Te 3 Made of Sb with a purity of 99.9% 2 Te 3 Powder smelted, Ge 2 Sb 2 Te 5 Made of 99.9% Sb 2 Te 3 powder and 99.9% GeTe powder smelted. Will Sb 2 Te 3 The powder was packed into a quartz tube with an inner diameter of 6.5 mm, and smelted into a rod-shaped Sb under vacuum. 2 Te 3 sample. Cut the rod-shaped sample into a cylindrical sample with a height of about 10mm. Use sandpaper to polish the upper and lower surfaces to #2000 and keep the upper and lower surfaces parallel. For Ge 2 Sb 2 Te 5 Sample shape is not required.

[0033] Utilize measuring equipment of the present invention to measure Sb 2 Te 3 and Ge 2 Sb 2 Te 5 Alloy density, the steps are as follows:

[0034] The alloy sample is placed on the sample stage 13; under vacuum condition, by the temperature controller 5 the Sb 2 Te 3 and Ge 2 Sb 2 Te 5 The alloy samples were heated to 600 and 700 °C respectively; through the image acquisition syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com