Inserting type gear

A plug-in, gear technology, applied in the field of mechanical parts, can solve the problems of non-removable, tooth surface wear, gear tooth damage, etc., and achieve the effect of compact plug-in and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

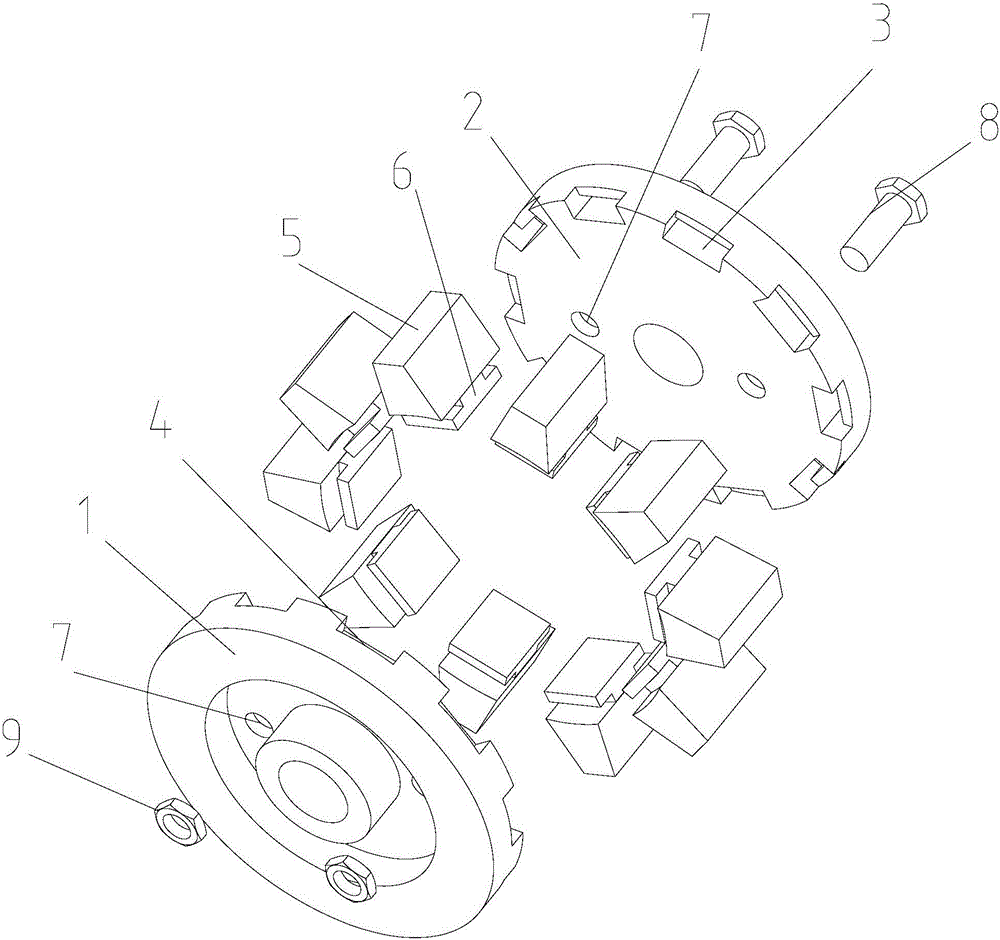

[0012] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0013] like figure 1 and figure 2 The shown plug-in gear includes a base wheel with a shaft hole in the center, and the base wheel includes a fixedly connected coaxial left base wheel 1 and a right base wheel 2, and the right base wheel 2 is close to the left base wheel The outer circular surface of side 1 is evenly spaced with right insertion grooves 3 arranged axially along the right base wheel 2, and the left base wheel 1 is provided with symmetrical left insertion grooves 4 corresponding to the right insertion grooves 3, so The size and structure of the left socket 4 and the right socket 3 are the same and the cross-section is L-shaped. Each of the left socket 4 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com