Roofing thermal insulation plate with wedge

A technology of insulation board and wedge, which is applied to roofs, roofs using flat/curved panels, and roof coverings, etc., can solve the damage of building structure moisture heave and frost heave, poor integrity of roof insulation system, and poor wind pressure resistance. and other problems, to achieve the effect of reducing water content, good waterproof effect and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

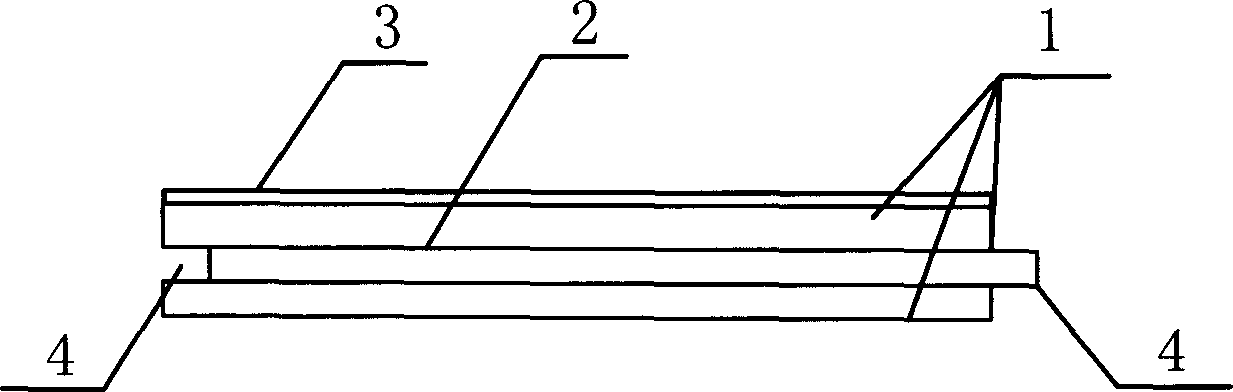

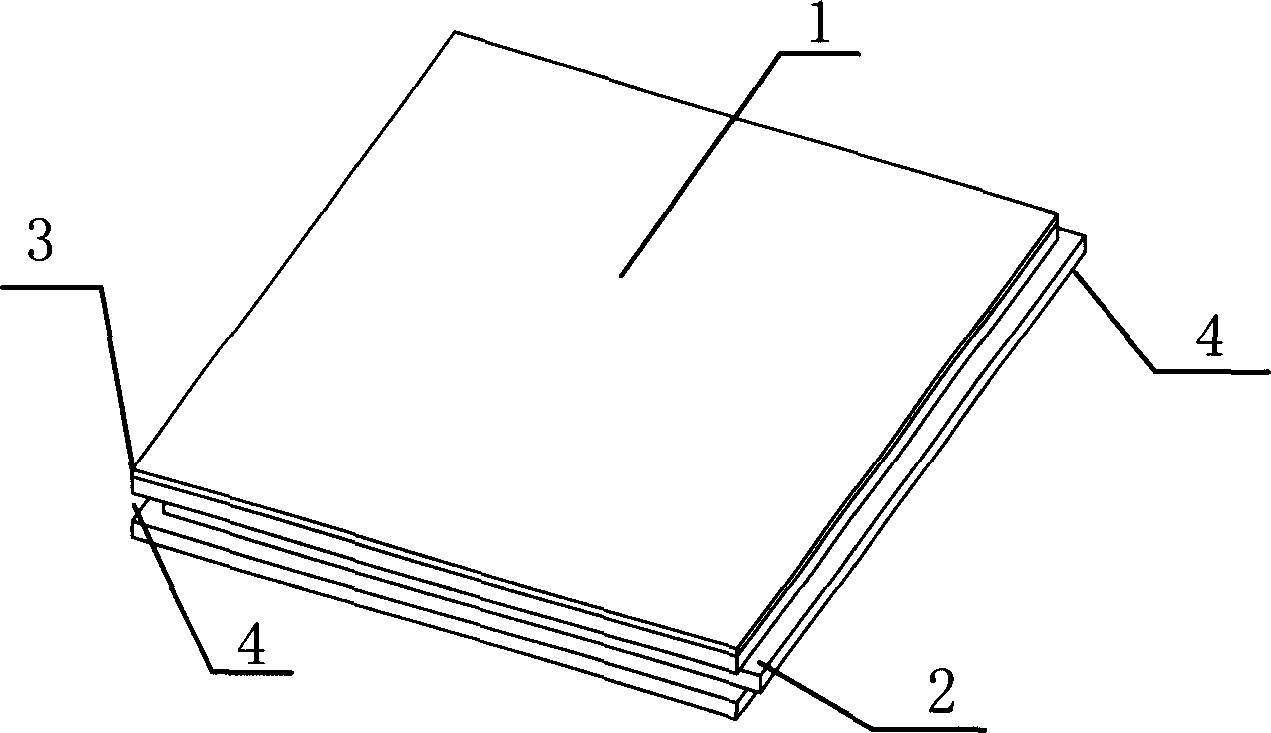

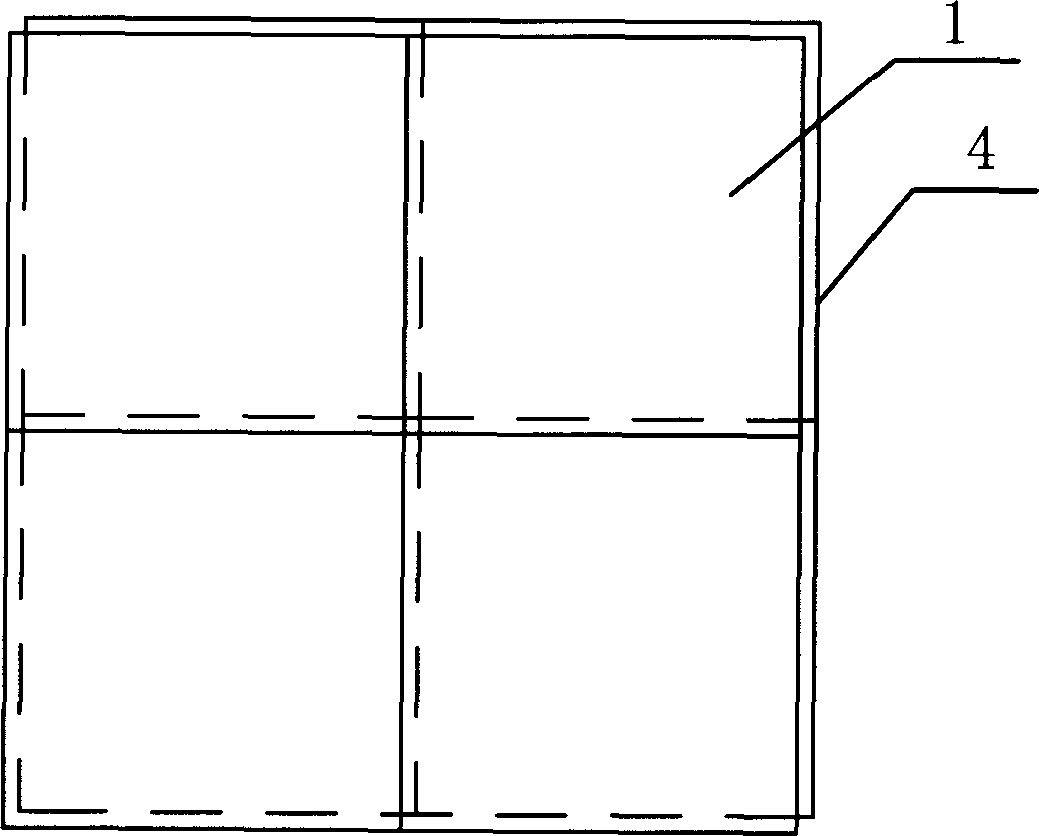

[0021] figure 1 The middle plate body 1 is composed of an insulating layer 2 and at least one protective layer 3 covering it. Wedge 4 is arranged on the periphery of insulation layer 2, and wedge 4 has 1 / 2 side length to be groove by insulation layer 2 peripheral side lengths, and another 1 / 2 side length is convex groove. When the two boards 1 are plugged together, the insulation layer 2 is completely plugged in, and there is no thermal bridge between them. There is a gap between the protective layers 3, and flexible waterproof fillers can be embedded in the gap. The shape of the plate body 1 is square, rectangular, rhombus or other special shapes, the area of the insulation layer 2 is less than 0.5 square meters, and its material can be flame-retardant expanded polystyrene board, XPS extruded board, rigid polyurethane foam board, phenolic Resin foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com