Storage conveying system and conveying method thereof

A conveying system and warehousing technology, which is applied in the warehousing and conveying system and its conveying field, can solve the problems of complex drive control mechanism, unreliable control, and complex control system of the battery quick-change system, so as to save track layout space and improve space utilization , The effect of improving the accumulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numerals indicate the same or similar components. It should be understood that the present invention is not limited to storage and transportation of rechargeable batteries. It is also suitable for storage and transportation of other goods, especially single Model of cargo components.

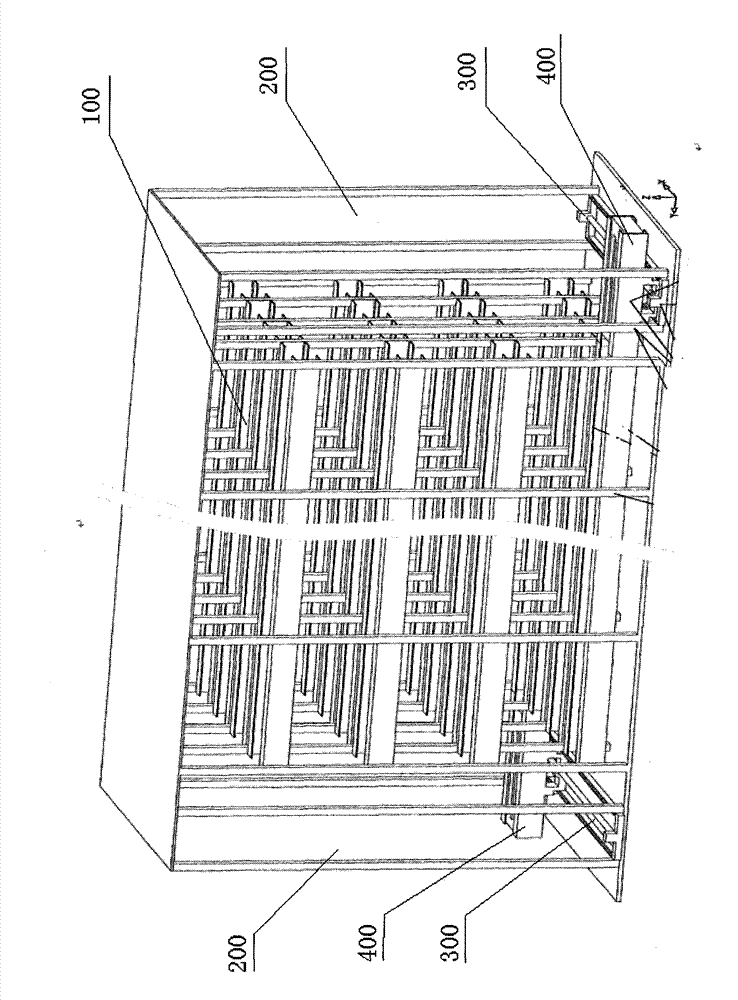

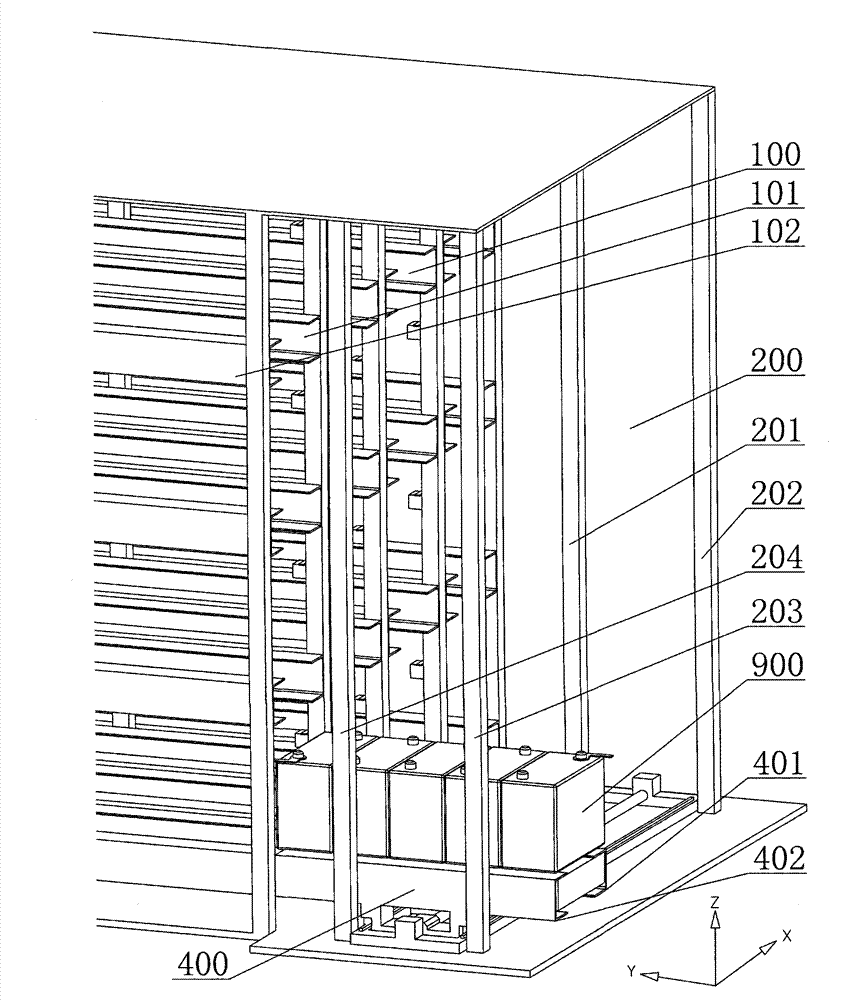

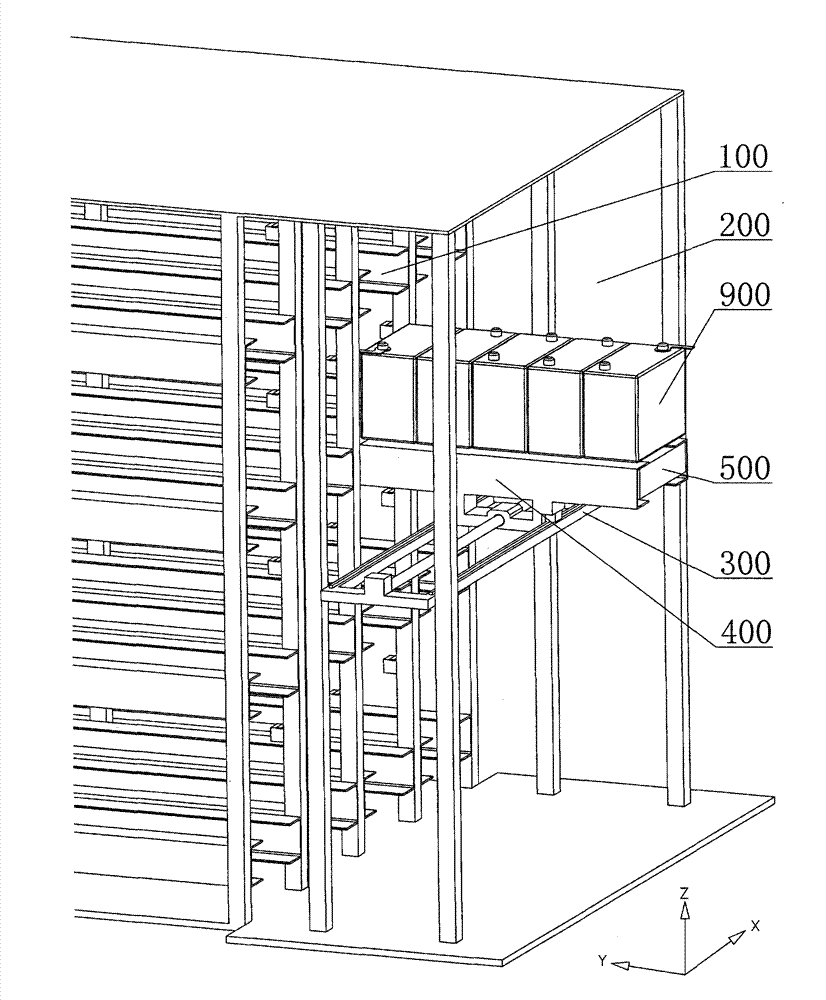

[0043] figure 1 It is the overall structure diagram of the storage and transportation system of the present invention, figure 2 Shows the working state of the rail docking transition device 400 of the present invention placed in the first-layer lifting frame; image 3 It shows the working state of the rail docking transition device 400 of the present invention placed in the third-layer lifting frame.

[0044] Such as figure 1 As shown, the storage and transportation system of the present invention includes a multi-layer and multi-row rack rail 100,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com