vacuum pump

一种真空泵、转子室的技术,应用在泵、泵元件、旋转活塞式泵等方向,能够解决妨碍干式真空泵的工艺气体吸入等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

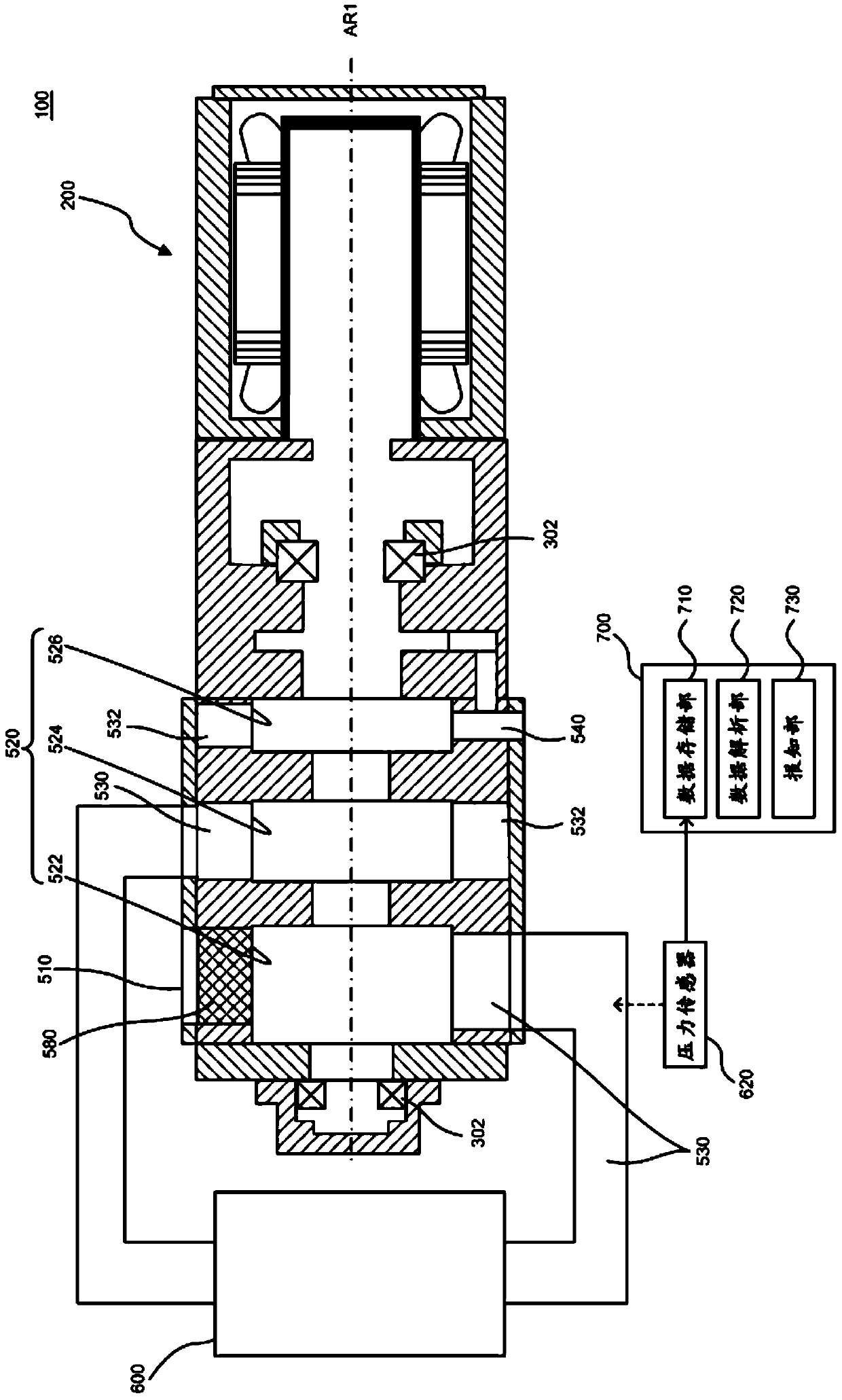

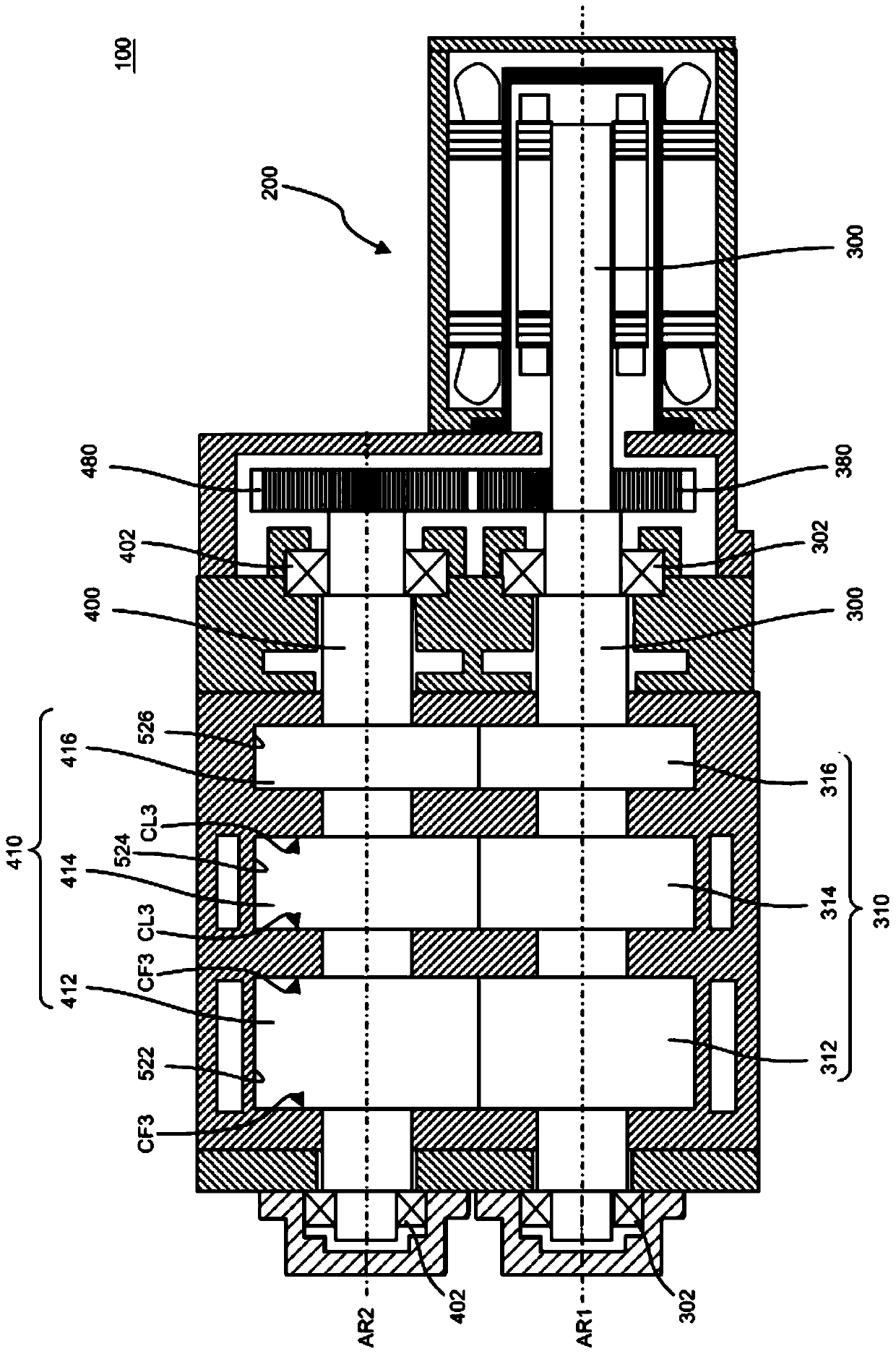

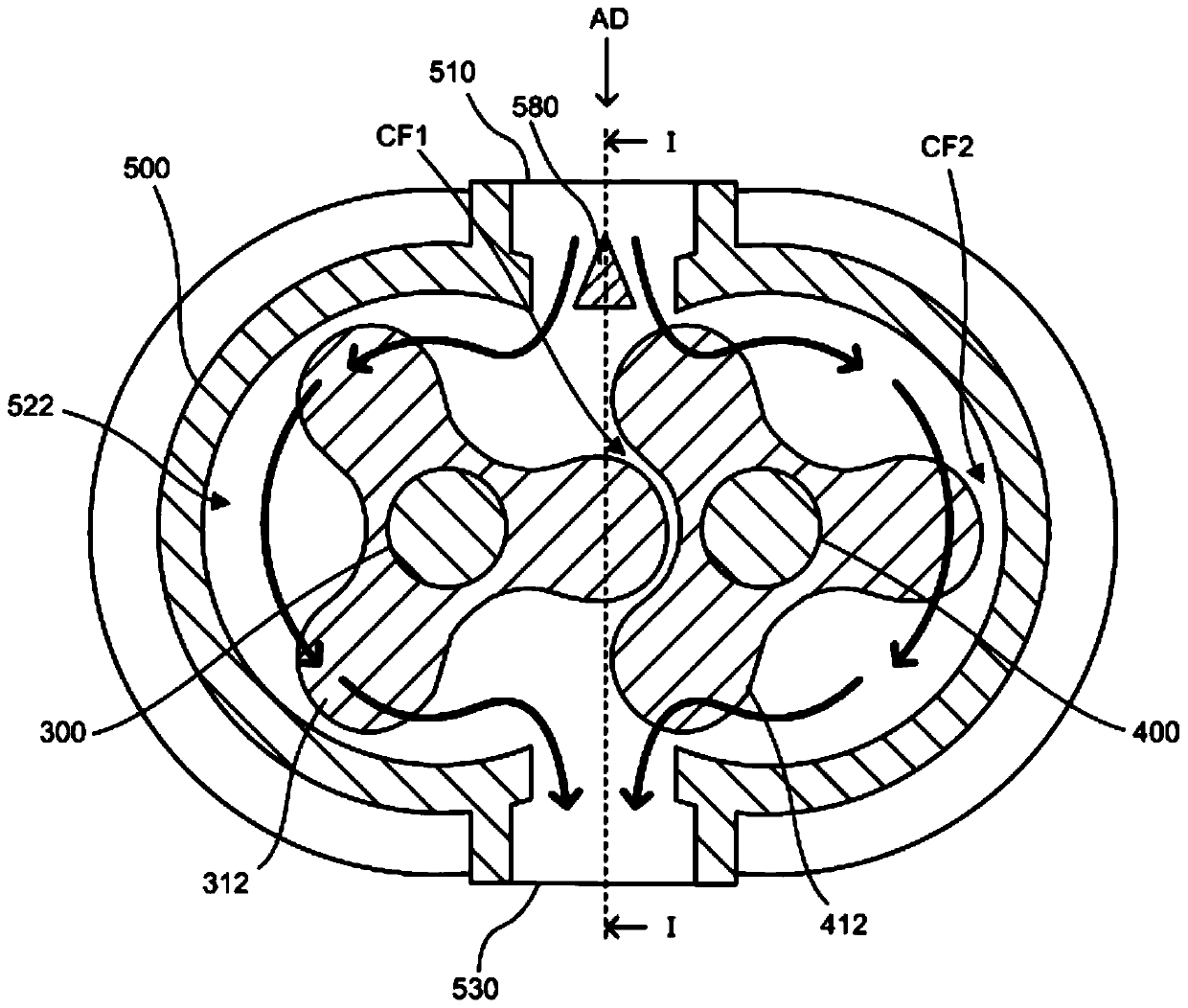

[0068] figure 1 It is a schematic configuration diagram showing the vacuum pump device of the present embodiment. figure 2 It is a schematic configuration diagram showing the vacuum pump device of this embodiment from another cross section. The vacuum pump device of the present embodiment is connected to a vacuum chamber (not shown) for performing CVD (Chemical Vapor Deposition), for example, and exhausts gas from the vacuum chamber. The vacuum pump device of the present embodiment can be suitably applied to a vacuum chamber in which the gas in the vacuum chamber contains solid foreign matter, especially when the solid foreign matter is a non-sublimable solid, but is not limited thereto. In addition, the vacuum pump device of this embodiment can be suitably applied to a vacuum chamber that generates light gas such as hydrogen, but is not limited thereto.

[0069] figure 1 A cross section including an axis line AR1 of one pump rotor 310 among a pair of pump rotors 310 and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com