A kind of preparation method of anti-pilling and snagging lace fabric

A ball snagging and lace technology, which is applied in the anti-pilling and snagging lace fabric and its preparation field, can solve the problem of poor softness of glass fiber and polyamide fiber, which affects the thin and elegant performance of lace fabric, and the film thickness is difficult to control And other problems, to achieve the effect of good wear resistance, good elasticity and small fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

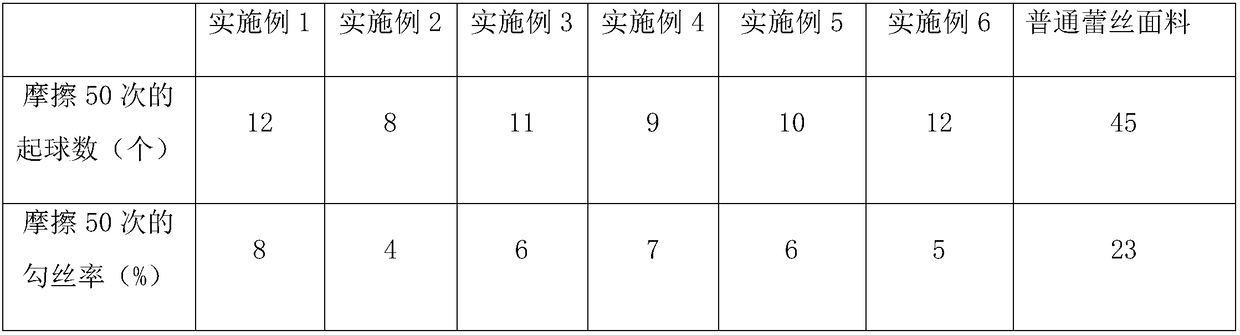

Examples

Embodiment 1

[0025] (1) Make 1 strand of 80D nylon 66, 2 strands of 40D superfine spandex fiber spandex and 1 strand of 150D DTY network yarn into strands, and then combine nylon strands, spandex strands and polyester strands After the gas is sprayed horizontally, it is twisted and paralleled with an intensity of 200 twists / 10cm to form a composite filament with network nodes.

[0026] (2) On the lace machine, the composite silk thread is manufactured to form a lace fabric with a horizontal density of 10 wales / cm and a vertical density of 45 rows / cm.

[0027] (3) After presetting the lace gray cloth at 150°C for 30s, spray fatty acid softener on both sides of the fabric respectively. The amount of fatty acid softener is 0.01% of the mass of the lace gray cloth. ℃ temperature and 55% humidity under high temperature and humidity setting for 1 min, to obtain the anti-pilling and snagging lace fabric.

Embodiment 2

[0029] (1) 1 strand of 80D nylon 66, 4 strands of 20D superfine spandex fiber spandex and 1 strand of 150D triangular matte yarn are formed into strands, and then nylon strands, spandex strands and polyester strands After the gas is sprayed horizontally, it is twisted and paralleled at a strength of 400 twists / 10cm to form a composite filament with network nodes.

[0030] (2) On the lace machine, the composite silk thread is manufactured to form a lace fabric with a horizontal density of 12 wales / cm and a vertical density of 50 rows / cm.

[0031] (3) After pre-setting the lace fabric at 160°C for 60s, spray fatty acid softener on both sides of the fabric respectively. The amount of fatty acid softener is 0.03% of the mass of the lace fabric. and 65% humidity under high temperature and humidity setting for 2 minutes to obtain a lace fabric with anti-pilling and snagging.

Embodiment 3

[0033] (1) Make 1 strand of 80D nylon 66, 2 strands of 20D superfine spandex fiber spandex and 1 strand of 150D DTY network yarn into strands, and then combine nylon strands, spandex strands and polyester strands After the gas is sprayed horizontally, it is twisted and paralleled with an intensity of 300 twists / 10cm to form a composite filament with network nodes.

[0034] (2) The composite silk thread is manufactured on a lace machine to form a lace fabric with a horizontal density of 11 wales / cm and a vertical density of 47 rows / cm.

[0035] (3) After pre-setting the lace fabric at 155°C for 40s, spray fatty acid softener on both sides of the fabric respectively. The amount of fatty acid softener is 0.02% of the mass of the lace fabric. and 60% humidity under high temperature and humidity setting for 1.5 minutes to obtain a lace fabric with anti-pilling and snagging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com