Nodular cast iron for vehicle speed reducer and preparation process of nodular cast iron

A preparation process and technology for reducers, which are applied in mechanical equipment, belts/chains/gears, transmission parts, etc., can solve the problems of short service life of reducers, small internal structure grains, and large equipment tonnage, etc., and increase the surface area. The effect of hardness, low preparation cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

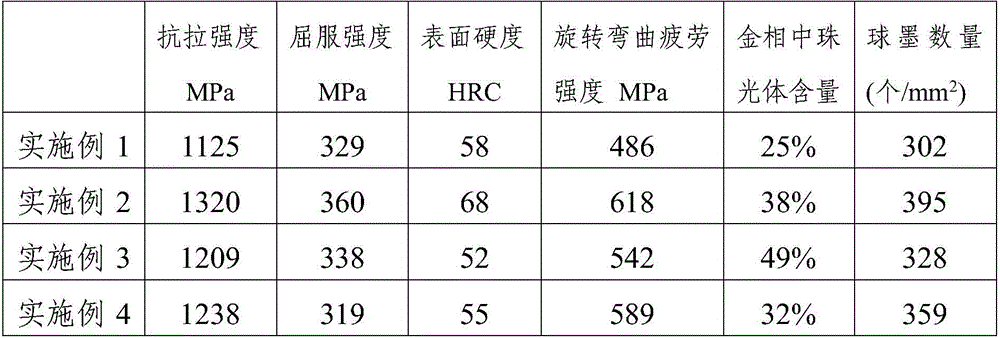

Examples

Embodiment 1

[0019] A preparation process of nodular cast iron for automobile reducer, comprising the following steps:

[0020] (1) Put pig iron and scrap steel into the electric furnace, raise the temperature to 1420-1430°C for smelting, raise the temperature to 1460-1470°C, add ferromanganese, ferromagnesium, rare earth elements and ferrosilicon for alloying treatment, and then adjust the content of each component Ratio, slag removal to remove surface scum;

[0021] (2) Carry out spheroidizing treatment to the molten iron in step (1) by the capping method, add 1.2% spheroidizing agent of the original molten iron quality, add inoculant at the same time, carry out inoculation treatment for the first time, and let stand for 3-5min; After spheroidizing, carry out the second inoculation treatment, add 0.2-0.3% inoculant, and adjust the composition of molten iron to carbon 3.2%, silicon 1.8%, manganese 0.6%, rare earth elements 0.08%, magnesium 0.23%, phosphorus≦0.06% , sulfur≦0.02%, then sla...

Embodiment 2

[0025] A preparation process of nodular cast iron for automobile reducer, comprising the following steps:

[0026] (1) Put pig iron and scrap steel into the electric furnace, raise the temperature to 1420-1430°C for smelting, raise the temperature to 1460-1470°C, add ferromanganese, ferromagnesium, rare earth elements and ferrosilicon for alloying treatment, and then adjust the content of each component Ratio, slag removal to remove surface scum;

[0027] (2) Carry out spheroidization treatment to the molten iron in step (1) by using the cover bag method, add 1.6% nodulizer of the original molten iron quality, add inoculant at the same time, carry out inoculation treatment for the first time, let stand for 3-5min ;After spheroidization, carry out the second inoculation treatment, add 0.2-0.3% inoculant, adjust the composition of molten iron to carbon 3.5%, silicon 1.6%, manganese 1.2%, rare earth elements 0.25%, magnesium 0.21%, phosphorus≦0.06 %, sulfur ≦ 0.02%, then remove ...

Embodiment 3

[0031] A preparation process of nodular cast iron for automobile reducer, comprising the following steps:

[0032] (1) Put pig iron and scrap steel into the electric furnace, raise the temperature to 1430-1440°C for smelting, raise the temperature to 1470-1480°C, add ferromanganese, ferromagnesium, rare earth elements and ferrosilicon for alloying treatment, and then adjust the content of each component The ratio is carbon 3.5-3.8%, silicon 1.8-2.5%, manganese 0.8-1.0%, rare earth elements 0.08-0.16%, magnesium 0.12-0.21%, phosphorus≦0.06%, sulfur≦0.02%, the balance is iron, slag removal remove surface scum;

[0033] (2) Carry out spheroidization treatment to the molten iron in step (1) by using the cover bag method, add 1.5% nodulizer of the original molten iron quality, add inoculant at the same time, carry out inoculation treatment for the first time, let stand for 3-5min ; After spheroidization, carry out the second inoculation treatment, add 0.2-0.3% inoculant, adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com