Remediation conditioner for chromium-contaminated soil and remediation method adopting remediation conditioner

A technology of chromium-contaminated soil and conditioner, applied in the field of soil remediation, can solve the problems of soil affecting sustainable utilization, etc., and achieve the effects of improving the passivation remediation effect, combining stability and being beneficial to growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A chromium-contaminated soil remediation improver, the soil composite improver is composed of the following raw materials in weight percentage: 20% ferrous sulfate, 20% calcium polysulfide, 20% humic acid resin, 20% cow dung, 20% bacterial residue .

[0039] Humic acid resin is obtained by the following method: Take sodium sulfonated humate and grind it, pass through a 80-120 mesh sieve, and mix the crushed sodium sulfonated humate with phenolic resin and hydrochloric acid with a concentration of 37wt% in a ratio of 1:2:1 After mixing evenly, cross-link and solidify at 260°C for 4 hours, wash with water until colorless, dry at 60°C for 7 hours, grind, and sieve. The particle size after sieving is ≤0.25mm, and then the obtained The crude humic acid resin was soaked in a calcium acetate solution with a concentration of 2mol / L for 5 hours, filtered, washed, and dried at 60°C for 7 hours.

[0040] The method for remediating chromium-contaminated soil by using the chromium-...

Embodiment 2

[0047] A chromium-contaminated soil repair and improver, the soil composite improver is composed of the following raw materials in weight percentage: 10% ferrous sulfate, 10% calcium polysulfide, 30% humic acid resin, 25% cow dung, 25% bacterial residue .

[0048] The preparation method of humic acid resin is the same as embodiment 1.

[0049] The method for remediating chromium-contaminated soil by using the chromium-contaminated soil remediation improver, the steps are as follows:

[0050] (1) Take the chromium-contaminated soil and crush it to a particle size below 2mm;

[0051] (2) Take ferrous sulfate (FeSO 4 ) and calcium polysulfide (CPS) are evenly mixed with the crushed chromium-contaminated soil to obtain the chromium-contaminated soil mixture; ferrous sulfate (FeSO 4 ) and the mass ratio of chromium-contaminated soil is 1:15;

[0052] (3) adding water to adjust the water content of the chromium-contaminated soil mixture is 28wt%, stirring for 8 minutes;

[0053...

experiment example

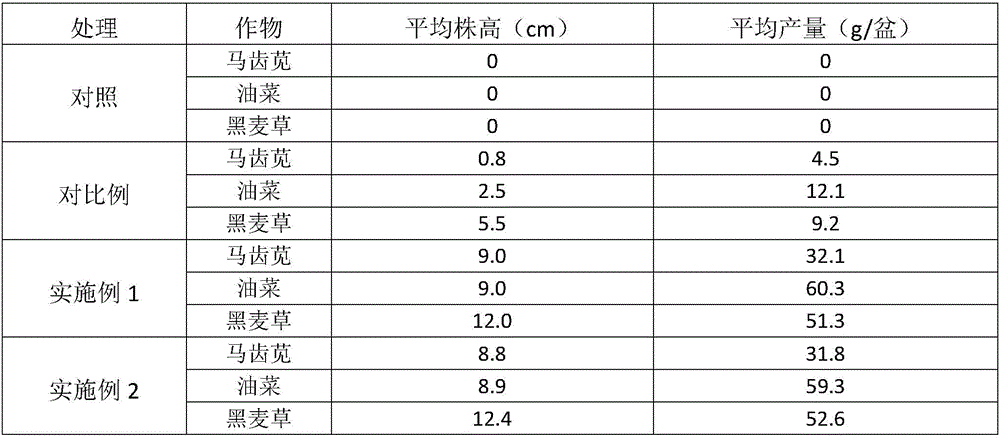

[0063] Experimental example: the application of the composite improver of the present invention in the remediation of chromium-contaminated soil and the growth of crops

[0064] 1. Test overview

[0065] 1.1. Test site: Chromium-contaminated soil was taken from Jiyang. The basic physical and chemical properties are as follows: pH is 7.83, organic matter content is 9.14g / kg, alkaline nitrogen content is 21.36mg / kg, available phosphorus content is 30.08mg / kg, available Potassium content is 170mg / kg, Cr 6+ The content is 95mg / kg. The tested crops were purslane, rapeseed and ryegrass.

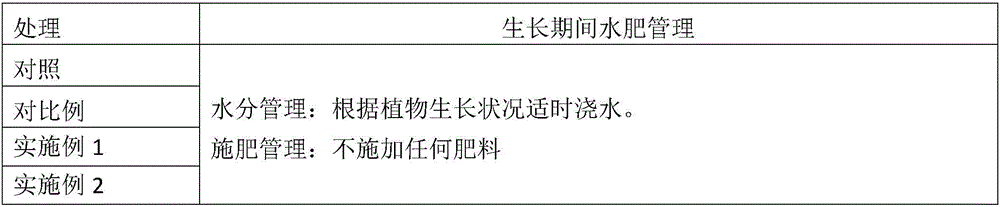

[0066] 1.2. Test settings

[0067] 1.2.1 Restoration test: The chromium-contaminated soil was repaired according to the method in Example 1.

[0068] 1.2.2 Pot test: 4 treatments (table 1) are set in the test, which are respectively control (unrepaired soil), treatment 1 (embodiment 1), treatment 2 (embodiment 2), treatment 3 (comparative example), each Treatments were repeated 4 times.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com