Organic fertilizer stack-type fermentation method with mushroom dreg as substrate

A fermentation method and organic fertilizer technology, applied in the direction of organic fertilizers, organic fertilizer preparation, inorganic fertilizers, etc., can solve the problem of organic fertilizer decomposing, the degree of organic fertilizer decomposing is not mentioned, and the production process is complicated. problems, to achieve the effects of good product quality, shortened fermentation time, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

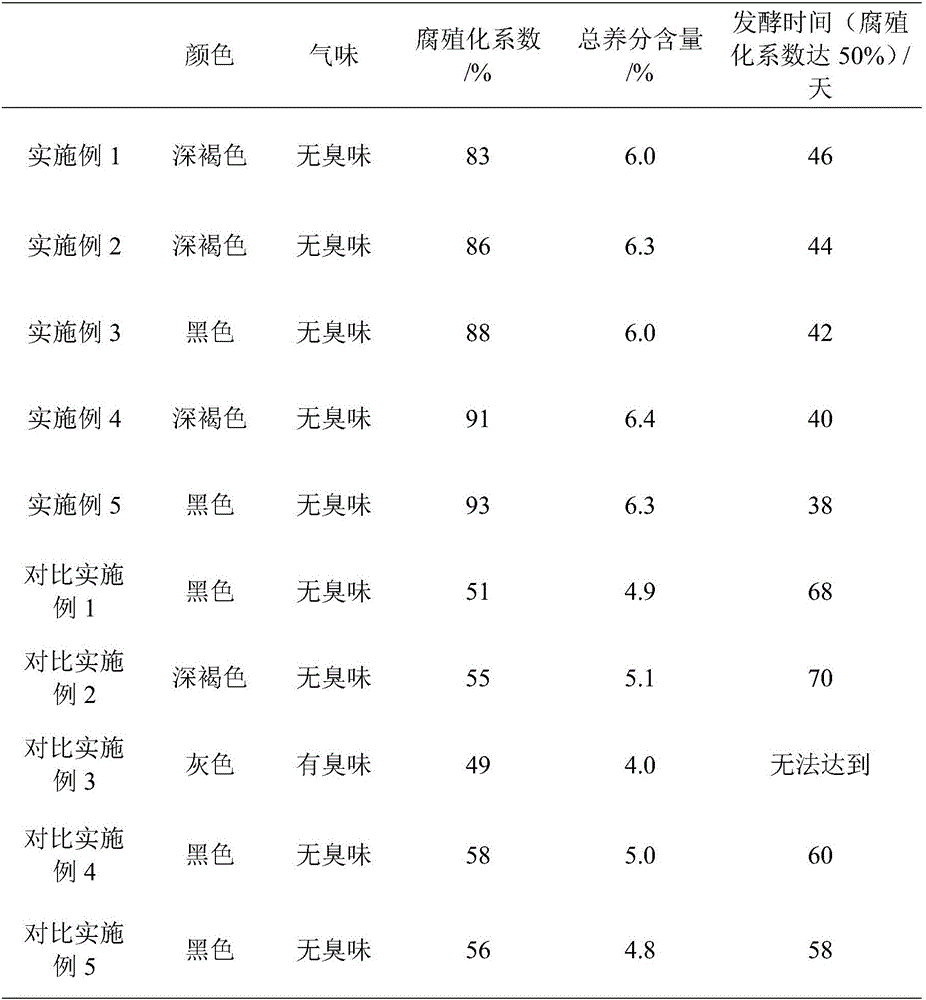

Examples

Embodiment 1

[0026] Follow the steps below to prepare organic fertilizer by stack fermentation:

[0027] (1) Preparation of fermentation raw materials: Take 50 parts of bacterial residue, 30 parts of pig manure, and 20 parts of kitchen waste and mix them uniformly, add Bacillus subtilis and nitrogen fertilizer, phosphate fertilizer, and potash fertilizer to it to adjust the total mixture The C / N ratio is 20, and the total nutrient content is 6.0%;

[0028] (2) Pre-fermentation: The fermented raw materials obtained in step (1) are composted in stacks. The pile height is set to 2m, and holes are punched at intervals of 1m. The hole diameter is 3cm, and the hole depth is to the bottom. When the temperature of the pile increases When it reaches 50°C, turn the fertilizer once and transfer it to the composting fermentation area;

[0029] (3) Composting fermentation: the result of step (2) is composted and fermented, the height of the pile is set to 3m, and the temperature of the pile at a depth of 30c...

Embodiment 2

[0032] Follow the steps below to prepare organic fertilizer by stack fermentation:

[0033] (1) Preparation of fermentation raw materials: Take 50 parts of bacterial residue, 30 parts of pig manure, and 20 parts of kitchen waste and mix them uniformly, add Bacillus subtilis and nitrogen fertilizer, phosphate fertilizer, and potash fertilizer to it to adjust the total mixture The C / N ratio is 20, and the total nutrient content is 6.0%;

[0034] (2) Pre-fermentation: The fermented raw materials obtained in step (1) are composted in stacks. The height of the stack is set to 2m, and the holes are punched at intervals of 1m. The diameter of the holes is 3cm, and the hole depth is to the bottom. When the temperature of the stack increases When it reaches 50°C, turn the fertilizer once and transfer it to the composting fermentation area;

[0035] (3) Composting fermentation: the result of step (2) is composted and fermented, the height of the pile is set to 3m, and the temperature of the p...

Embodiment 3

[0039] Follow the steps below to prepare organic fertilizer by stack fermentation:

[0040] (1) Preparation of fermentation raw materials: Take 60 parts of bacteria residue, 30 parts of cow dung, and 10 parts of food waste and mix uniformly by weight, add Bacillus subtilis, Bacillus licheniformis, nitrogen fertilizer, phosphate fertilizer, potash fertilizer, and adjust The C / N ratio of the total mixture is 22, and the total nutrient content is 6.3%;

[0041] (2) Pre-fermentation: The fermented raw materials obtained in step (1) are composted in stacks. The height of the pile is set to 1.5m, and holes are punched at intervals of 1m. The diameter of the holes is 4cm, and the depth of the holes is to the end. When the temperature of the pile rises When the temperature reaches 52℃, the fertilizer will be turned once and transferred to the composting fermentation area;

[0042] (3) Pile fermentation: The result of step (2) is piled and fermented. The height of the pile is set to 2.5m. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com