A crucible manufacturing process for smelting rare and precious metals

A technology of rare and precious metals and manufacturing technology, which is applied in the field of crucible manufacturing, can solve the problems of inability to form and affect the service life of the crucible, and achieve the effects of low cost, high promotion and application value, and optimized sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

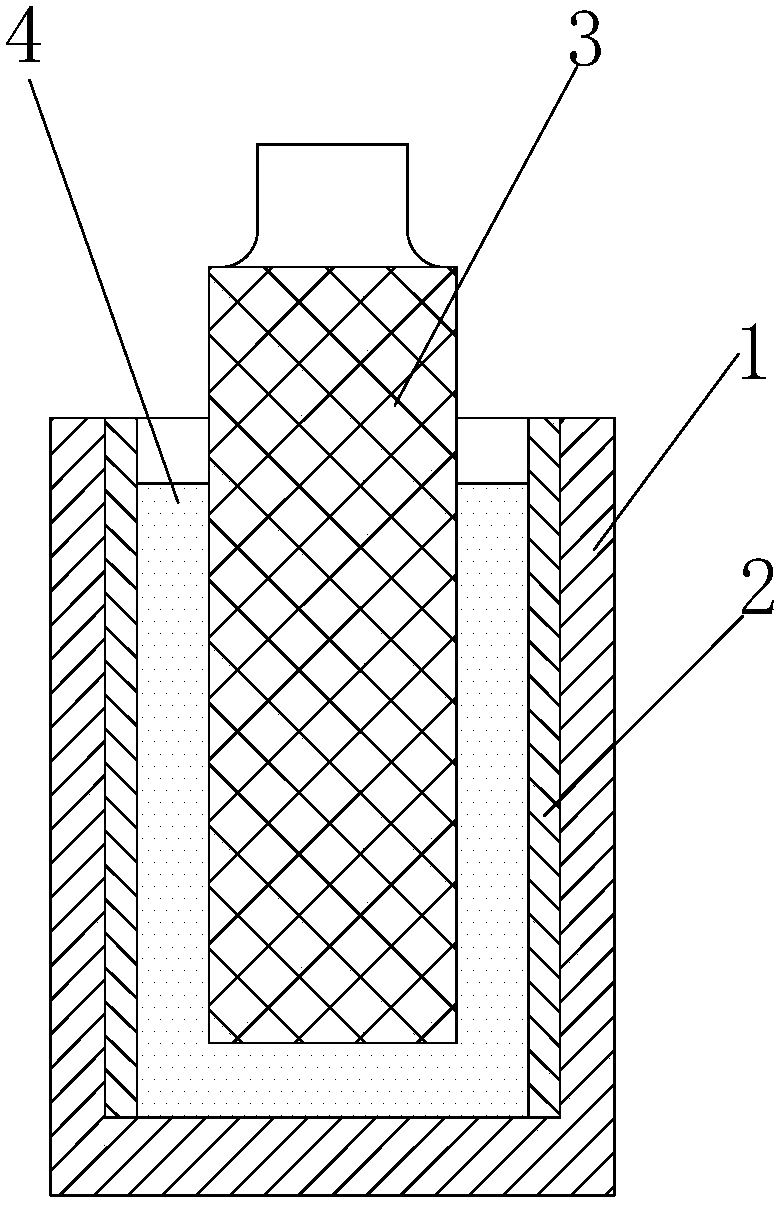

Image

Examples

Embodiment 1

[0032] The crucible for smelting rare and precious metals required in this embodiment is a crucible for smelting beryllium. The manufacturing process of the crucible for smelting rare and precious metals in this embodiment includes the following steps:

[0033] Step 1, using a powder press to press the oxide powder of rare and precious metals into a block-shaped billet, then placing the block-shaped billet in a crusher for crushing, and then using a sieving machine to sieve the crushed block-shaped billet to obtain Billets with multiple particle sizes; the billets with multiple particle sizes include: fine-grained billets with a particle diameter of less than 2 mm, medium-grained billets with a particle diameter of 2 mm to 5 mm, and coarse grains with a particle diameter greater than 5 mm and less than 10 mm. Particle size blank;

[0034] In this embodiment, the oxide powder of the rare metal is beryllium oxide powder;

[0035] Step 2, adding the fine-grained billet, medium-...

Embodiment 2

[0042] The crucible for smelting rare and precious metals required in this embodiment is a crucible for smelting vanadium. The manufacturing process of the crucible for smelting rare and precious metals in this embodiment includes the following steps:

[0043] Step 1, using a powder press to press the oxide powder of rare and precious metals into a block-shaped billet, then placing the block-shaped billet in a crusher for crushing, and then using a sieving machine to sieve the crushed block-shaped billet to obtain Billets with multiple particle sizes; the billets with multiple particle sizes include: fine-grained billets with a particle diameter of less than 2 mm, medium-grained billets with a particle diameter of 2 mm to 5 mm, and coarse grains with a particle diameter greater than 5 mm and less than 10 mm. Particle size blank;

[0044] In this embodiment, the oxide powder of the rare metal is vanadium oxide powder;

[0045] Step 2, adding the fine-grained billet, medium-gr...

Embodiment 3

[0052] The crucible for smelting rare and precious metals required in this embodiment is a crucible for smelting beryllium. The manufacturing process of the crucible for smelting rare and precious metals in this embodiment includes the following steps:

[0053] Step 1, using a powder press to press the oxide powder of rare and precious metals into a block-shaped billet, then placing the block-shaped billet in a crusher for crushing, and then using a sieving machine to sieve the crushed block-shaped billet to obtain Billets with multiple particle sizes; the billets with multiple particle sizes include: fine-grained billets with a particle diameter of less than 2 mm, medium-grained billets with a particle diameter of 2 mm to 5 mm, and coarse grains with a particle diameter greater than 5 mm and less than 10 mm. Particle size blank;

[0054] In this embodiment, the oxide powder of the rare metal is beryllium oxide powder;

[0055] Step 2, adding the fine-grained billet, medium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com