Crane with curve motion function

A crane and curve technology, which is applied in the directions of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problems of high cost, complex structure of wheel set consumables, and difficulty in running track to meet the operation of gantry cranes, and achieves a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

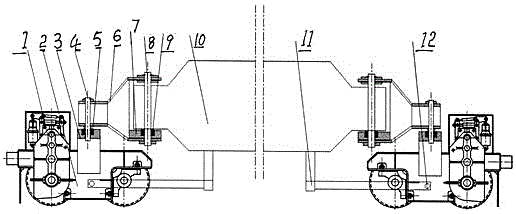

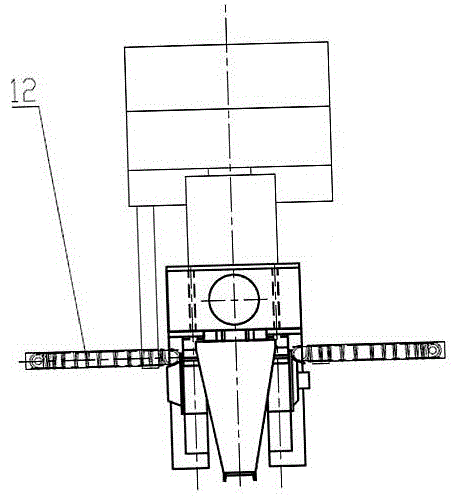

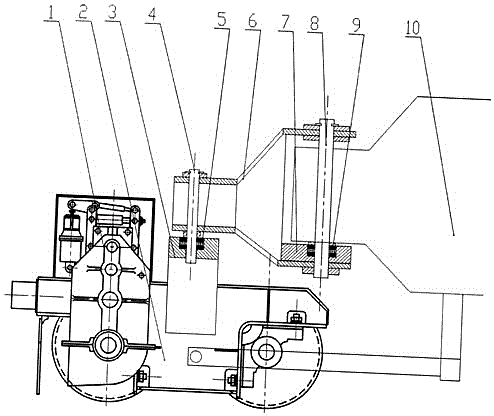

[0009] An embodiment of a crane capable of curve operation in the present invention is as follows: Figure 1-5 As shown, the cart running mechanism 1 is mounted on the trolley 2 for walking of the cart. The cart running mechanism is the same as the traditional cart running mechanism, and is also composed of a motor, a brake wheel coupling, a brake, Composed of reducer and wheels, the wheels are double rims, and the specific connection structure will not be described in detail.

[0010] The upper middle part of the trolley 2 is equipped with a trolley pressure bearing chamber 3, and a pressure bearing 5 is housed therein. Further, a trolley pressure bearing chamber 3 is respectively arranged in the middle of each wheel group and fixed on the on the trolley,

[0011] The two ends of the ground beam are respectively connected with a rocking arm 6, and the rocking arm 6 is as Figure 4 As shown, the diameter of the head end 6-1 of the rocker arm 6 is small, and the opening diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com