Injection mould of automotive plate structure

A technology of injection mold and flat plate, which is applied to flat products, household utensils, and other household utensils. It can solve the problems of poor injection molding quality, long machining time, and low efficiency, so as to increase injection molding quality, increase injection molding efficiency, and facilitate use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

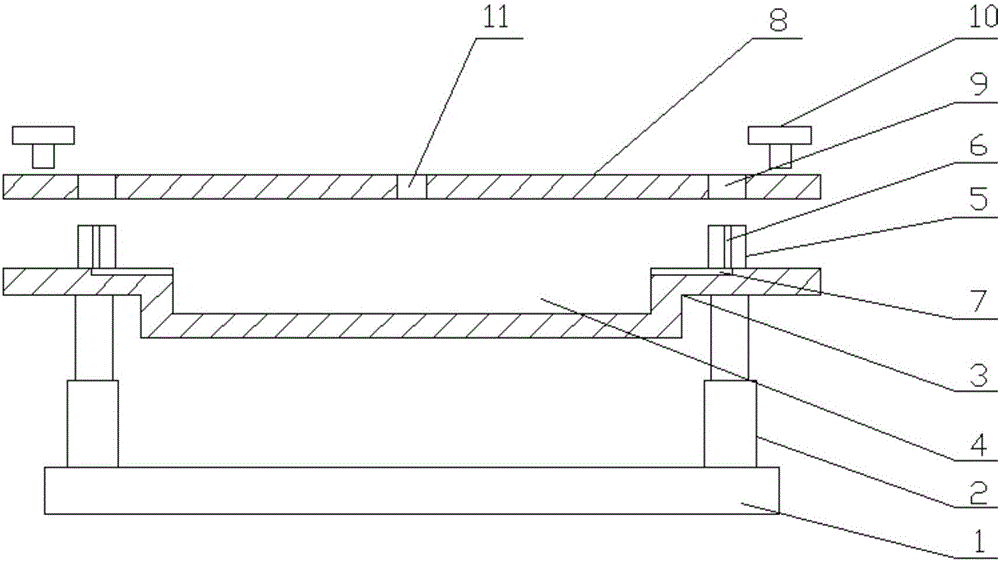

[0014] Such as figure 1 Shown, a kind of injection mold of automobile plate structure, comprises a base 1, and the both sides of described base 1 is equipped with support bar 2, and the upper end of described support bar 2 is equipped with mold body 3; Described mold body 3 The middle part is provided with a mold cavity 4 that is sunken downward; An injection channel 7 communicating with the injection port 6 is also provided on the upper side surface, and the injection channel 7 extends into the mold cavity 4 .

[0015] The top of the mold body 3 is also provided with a mold cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com