A multi-station lower plate device for eccentric polishing machine

A work station and polishing machine technology, which is applied to surface polishing machine tools, grinding drive devices, grinding machine parts, etc., can solve the problems of low production efficiency, loading and unloading, unfavorable automatic mass production, etc. rate and production capacity, the effect of continuous polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

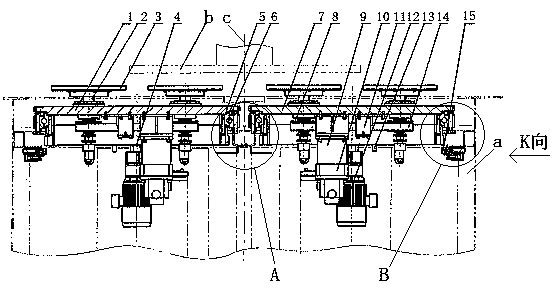

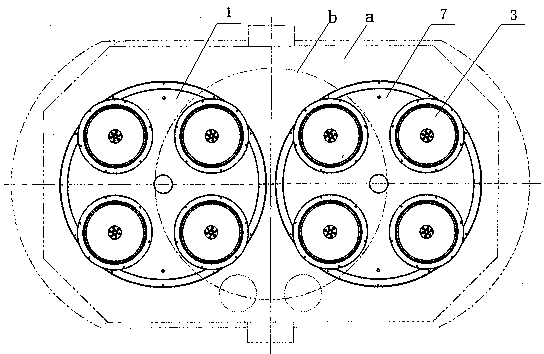

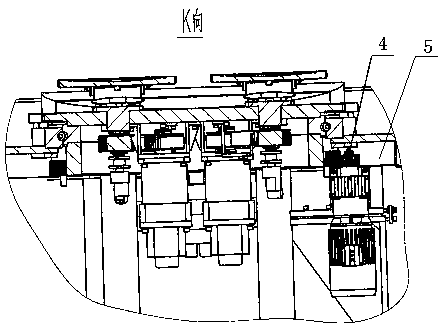

[0016] See figure 1 —— Figure 5 , the multi-station lower plate device for eccentric polishing machine provided by the present invention comprises a station disc 1 and a station disc drive mechanism, a workpiece disc 3 and a workpiece disc drive mechanism on the frame a, and the station disc 1 and 7 are two located under the upper plate b, and the two station plates 1 and 7 are symmetrically distributed on both sides of the center line c of the upper plate b, and each station plate 1 and 7 are evenly distributed four The workpiece disc 3 is such that two workpiece discs 3 are always covered by the upper disc b on each station disc 1,7. Since the upper plate b only indirectly exerts pressure on the half sides of the two station plates 1 and 7, rather than the entire plate surface is evenly stressed, so the station plates 1 and 7 need to bear a large overturning moment. A large-diameter, high-rigidity slewing bearing 6 is respectively designed and installed below the 7 to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com