An eccentric multi-station polishing machine

A multi-station, polishing machine technology, applied in the direction of grinding frame, grinding workpiece support, grinding bed, etc., can solve the problems of unable to increase production capacity and low utilization rate, achieve continuous polishing and improve utilization rate and the effect on production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

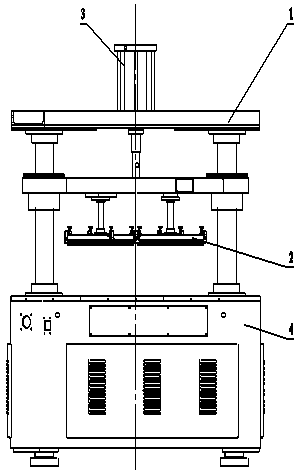

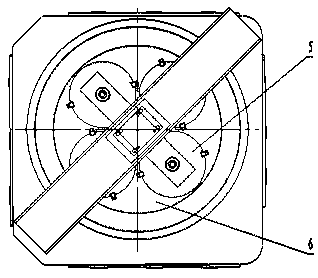

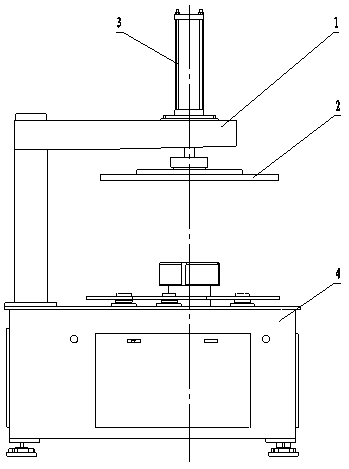

[0014] See Figure 5 , Image 6 , the eccentric multi-station polishing machine provided by the present invention includes a frame 4, a polishing disc 2 arranged on the frame, a workpiece disc 5, a station disc 6, 7 and a pressurizing system 3; the polishing disc 2 is set At the upper end of the frame, the pressurization system 3 is arranged on the frame 4 through the support 1; the work disks 5 distributed in the circumference are arranged on the work station disks 6 and 7; The two workstation discs 6, 7 are placed below the polishing disc 2 and distributed eccentrically and symmetrically with respect to the center line of the polishing disc 2, so that part of the workpiece disc 5 on the workstation discs 6, 7 is covered by the polishing disc 2 ; The pressurization system 3 drives the polishing disc 2 to lift and press the workpiece on the workpiece disc 5 through the cylinder, and the rotation of the workpiece disc 5 is connected to the servo motor by the rotary spindle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com