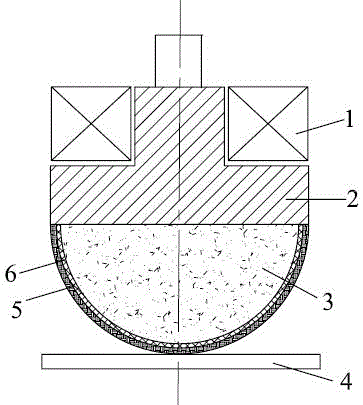

Flexible polishing method and device based on magnetorheological colloid or magnetorheological foam material

A foam material and flexible polishing technology, applied in the field of flexible polishing and devices based on magnetorheological colloids or magnetorheological foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Step 1. The elastic polishing pad is elastically supported by the magnetorheological colloid or the magnetorheological foam material, and the initial stiffness of the magnetorheological colloid or the magnetorheological foam material is determined according to the process parameters of the polished part;

[0019] Magnetorheological colloid is a new type of magnetorheological material composed of magnetic particles, carrier liquid and polymer glue. The main difference between magnetorheological glue and magnetorheological fluid is that colloid is added to magnetorheological colloid, and colloid Part of the network structure formed in the carrier liquid is adsorbed on the surface of the magnetic particles, and part of it is dispersed in the carrier liquid. On the one hand, the gravity of the particles is evenly distributed in the matrix, thereby significantly improving their sedimentation stability; on the other hand, the particle surface The network structure increases th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com