Ag2CrO4-loaded g-C3N4 composite photocatalyst and preparation method and application thereof

A technology of g-c3n4 and -g-c3n4, which is applied in the field of g-C3N4 composite photocatalyst and its preparation, can solve the problems of unfavorable material loading and dispersion, inability to form flakes, low photocatalytic activity, etc., and achieve inhibition of photocorrosion Phenomenon, enhanced photoresponse degree, small particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

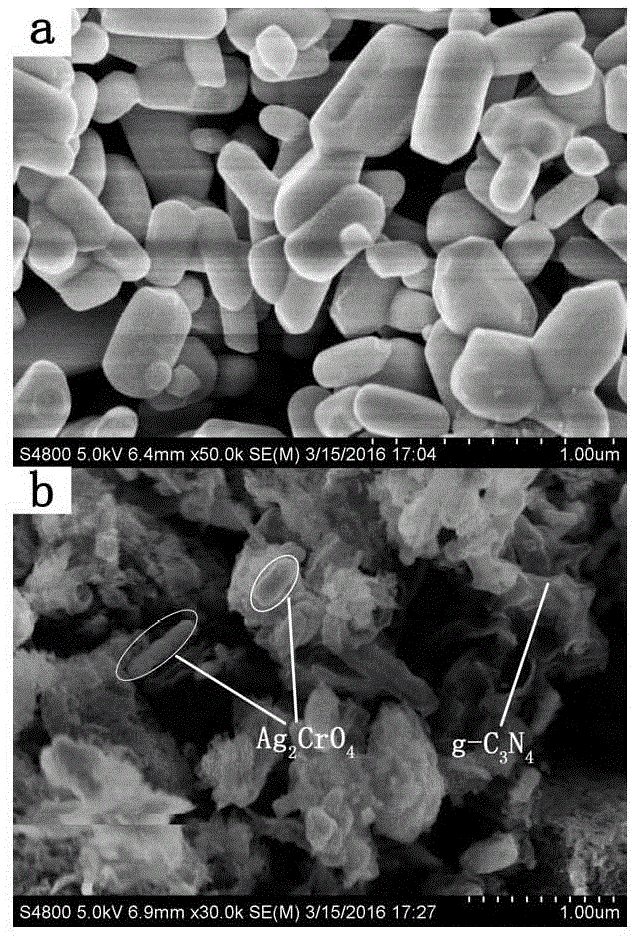

[0039] A kind of Ag of the present invention 2 CrO 4 Loaded g-C 3 N 4 Composite photocatalyst, Ag 2 CrO 4 Loaded g-C 3 N 4 Composite photocatalyst with g-C 3 N 4 Nanosheet as carrier, g-C 3 N 4 Nanosheet carrier modified with Ag 2 CrO 4 nanoparticles.

[0040] Among them, Ag 2 CrO 4 Nanoparticles were aggregated on g-C by co-precipitation method 3 N 4 The surface of the nanosheet carrier, Ag 2 CrO 4 and g-C 3 N 4 The mass ratio is 1:2.

[0041] The above Ag 2 CrO 4 Loaded g-C 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0042] (1) Put 5.0 g of melamine in a ceramic crucible, cover it with a lid, place it in a muffle furnace for roasting, raise the temperature from room temperature to 500 °C at a rate of 2 °C / min, and keep it for 2 h; The temperature was raised to 520 °C, kept for 2 h, cooled to room temperature, and ground to obtain g-C 3 N 4 Powder material.

[0043] (2) Weigh 1.0 g of g-C obtained in s...

Embodiment 2

[0056] A kind of Ag of embodiment 1 2 CrO 4 Loaded g-C 3 N 4 The application of composite photocatalyst in methyl orange dye wastewater treatment comprises the following steps:

[0057] (1) Weigh 20 mg of Ag prepared in Example 1 2 CrO 4 Loaded g-C 3 N 4 The composite photocatalyst was added to 100 mL of methyl orange dye wastewater with an initial concentration of 10 mg / L in a light-proof environment to obtain a mixed solution, which was placed in a photocatalytic reaction device after adsorption for 2 h.

[0058] (2) A 300W xenon lamp was used for photocatalytic reaction. Measure the absorbance value of the reaction solution at a wavelength of 464 nm at time t, combine the standard curve to obtain the concentration C of methyl orange at time t, and calculate the removal rate D of methyl orange according to the formula D=(Co-C) / Co×100% , where Co is the initial concentration of methyl orange.

[0059] Weigh respectively 20 mg of g-C prepared in Example 1 3 N 4 and ...

Embodiment 3

[0063] Ag after the reaction in embodiment 2 2 CrO 4 / g -C 3 N 4 The composite catalyst material was collected by centrifugation, washed with a large amount of water and ethanol, and dried in an oven at 60 °C for 12 h, and then the photocatalytic process in Example 2 was repeated. The test was repeated 5 times, and the photocatalytic experiment was tested 5 times After Ag 2 CrO 4 / g -C 3 N 4 Composite catalyst material to the removal rate of dyestuff, cycle experiment result sees Figure 7 . Depend on Figure 7 It can be seen that in the fifth photocatalytic experiment, the photocatalytic removal rate can still reach 80%, indicating that this material has good photocatalytic stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com