Preparation method and application of a fast ion conductor coating modified lithium ion battery positive electrode material

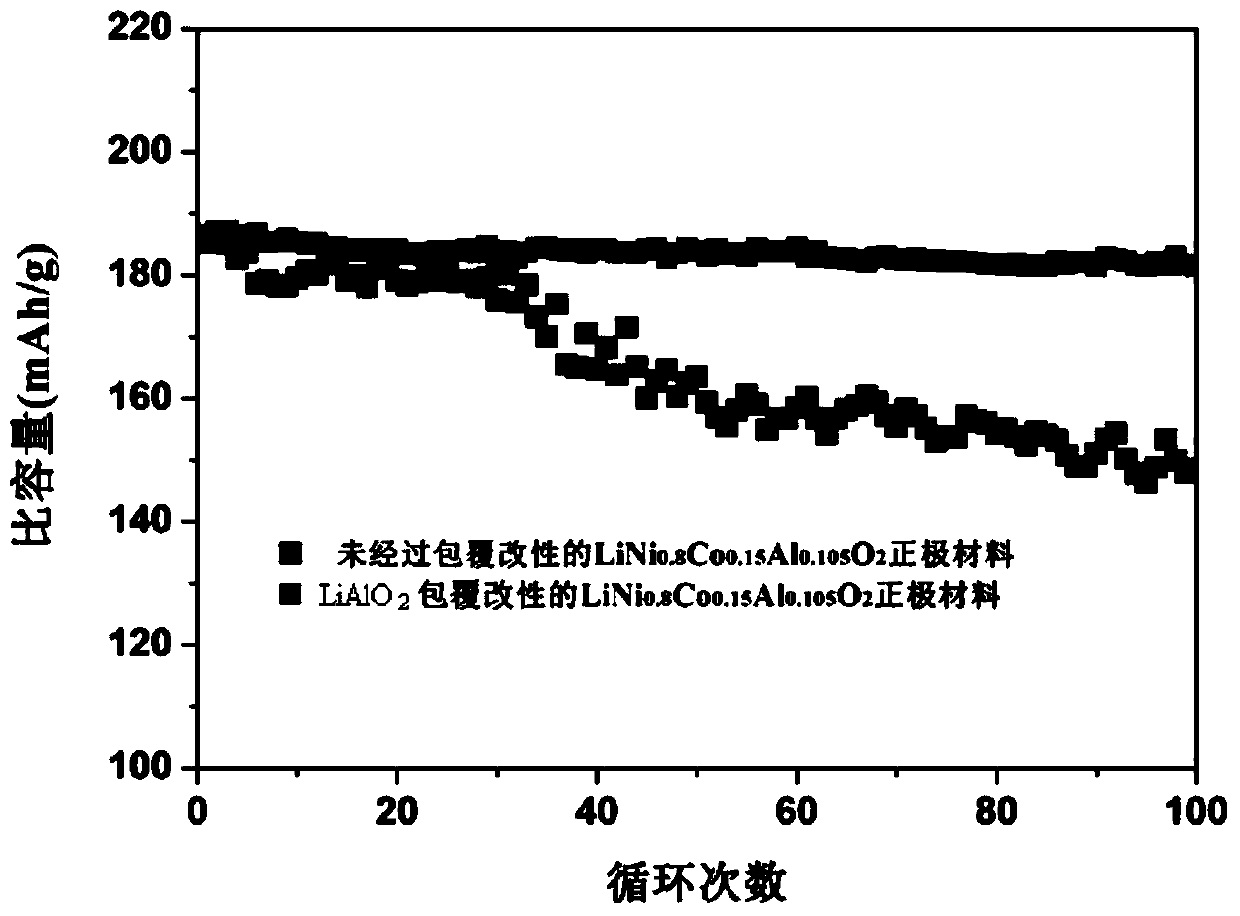

A technology of lithium ion battery and positive electrode material is applied in the preparation of fast ion conductor coating modified lithium ion battery positive electrode material, application in lithium ion battery, and the field of preparation of modified lithium ion battery positive electrode material, which can solve the problem of fast ion conductor The operation is complicated, it is difficult to industrialize production, and the cost is high. It can improve the electrochemical performance, prevent dissolution and loss, and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

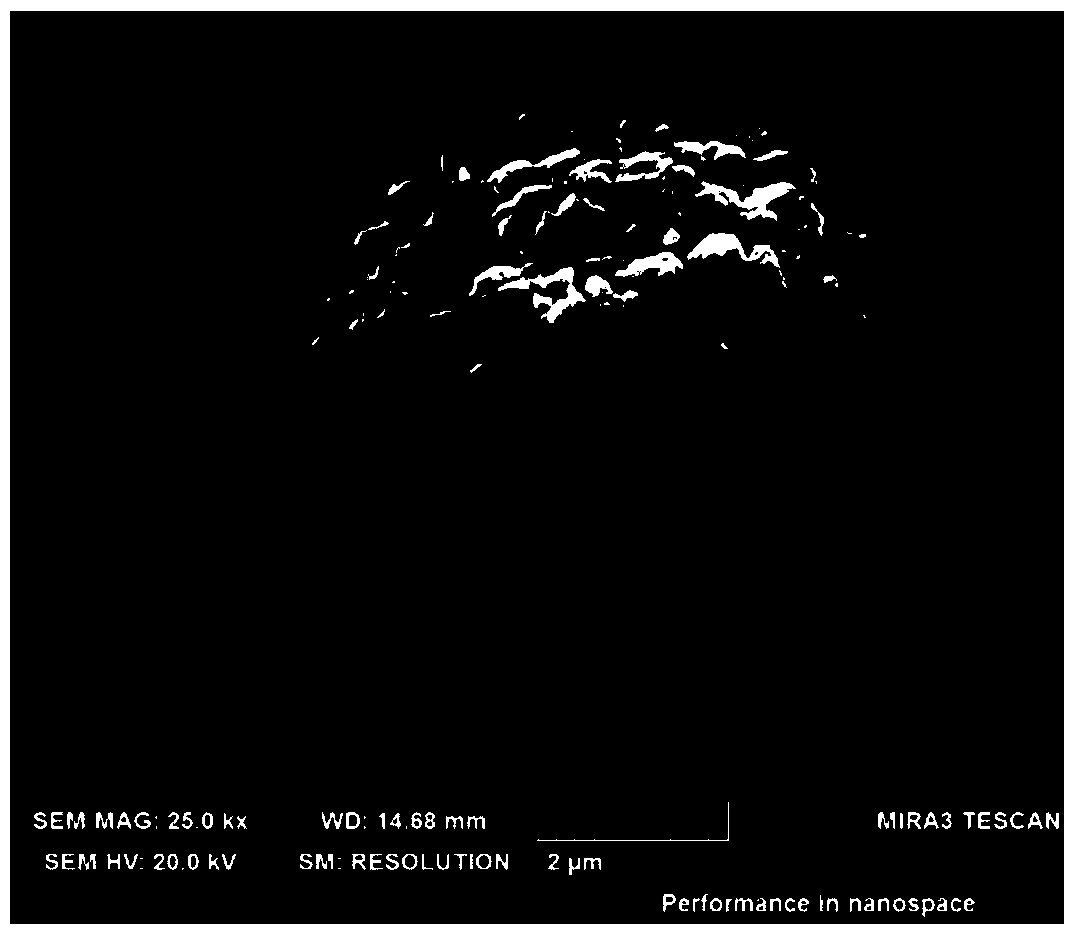

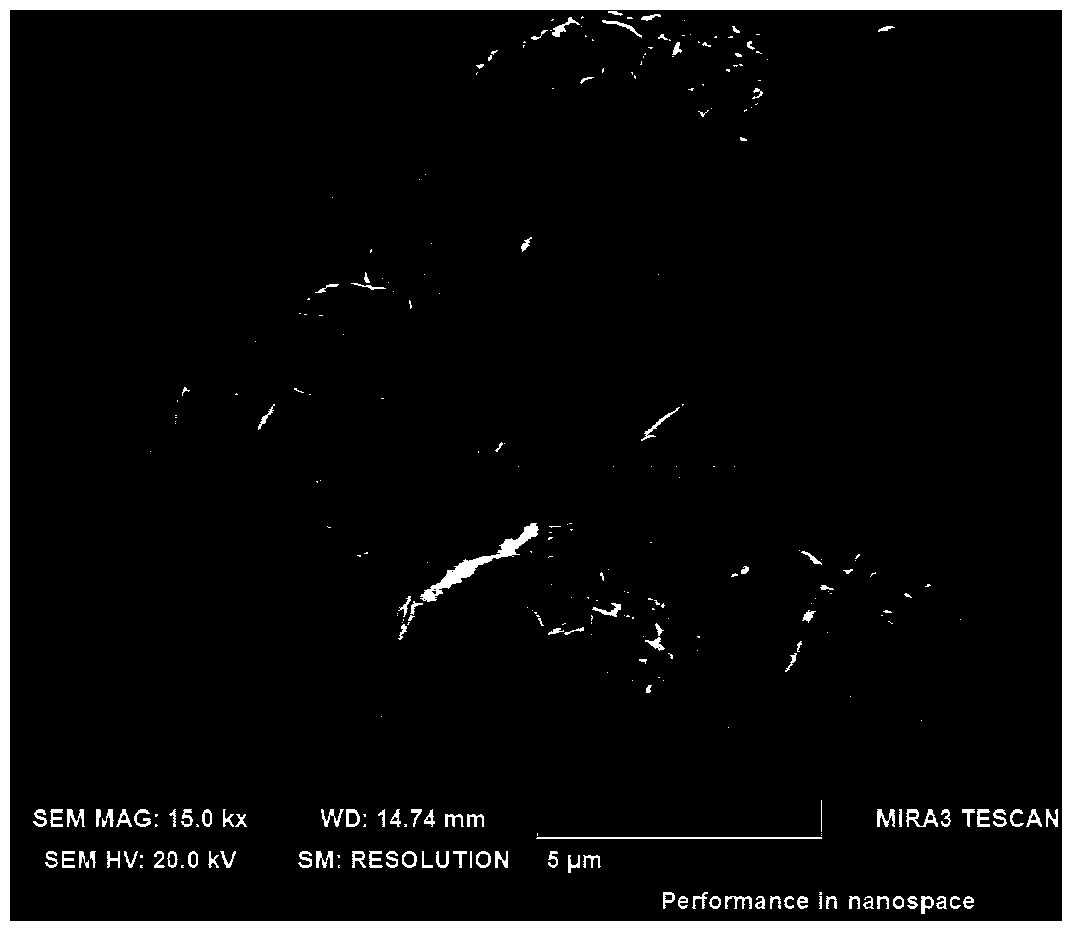

[0035] (1) According to LiAlO 2 The relative positive electrode material is 1% mass percent to weigh ultrafine (nanoscale) aluminum powder and LiNi powder with a particle diameter of 300nm 0.5 co 0.2 mn 0.3 o 2 The positive electrode material was added to a steel ball mill jar containing agate balls with a capacity of 250mL, and then the speed was adjusted to 400p / min for grinding for 2h.

[0036] (2) aluminum powder and LiNi after grinding activation in step (1) 0.5 co 0.2 mn 0.3 o 2 The positive electrode material mixture was added into a three-necked flask containing 100 mL of a LiCl solution with a concentration of 1 mol / L, and stirred and reacted at 50° C. for 1 h.

[0037] (3) Wash the precipitate obtained in step (2) with deionized water for 3 times, then wash with absolute ethanol for 3 times, then filter, and keep the filter cake in a blast oven at 80°C for 12 hours to obtain xLi + ·Al(OH) 3 ·yH 2 The precursor of O-coated cathode materials.

[0038] (4) Pu...

Embodiment 2

[0045] (1) According to LiAlO 2 The relative positive electrode material is 0.5% mass percent to weigh ultrafine aluminum powder (nano-scale) and LiNi with a particle diameter of 100nm respectively. 0.85 co 0.05 mn 0.1 o 2 Add the positive electrode material into a 250mL steel ball mill jar filled with agate balls, and then adjust the rotation speed to 500p / min for grinding for 4h.

[0046] (2) aluminum powder and LiNi after grinding activation in step (1) 0.85 co 0.05 mn 0.1 o 2 The positive electrode material mixture is added to the 100mL concentration of 0.5mol / L LiNO 3 In the three-necked flask of the solution, the reaction was stirred at 60° C. for 2 h.

[0047] (3) Wash the precipitate obtained in step (2) with deionized water for 3 times, then wash with absolute ethanol for 3 times, then filter, and keep the filter cake in a blast oven at 80°C for 12 hours to obtain xLi + ·Al(OH) 3 ·yH 2 The precursor of O-coated cathode materials.

[0048] (4) Put the precu...

Embodiment 3

[0052] (1) According to LiAlO 2 The relative positive electrode material is 2% mass percent to take the superfine aluminum powder (nano-scale) and LiNi with a particle diameter of 100nm 0.333 co 0.333 mn 0.333 o 2 The positive electrode material was added to a 250mL steel ball mill jar filled with agate balls, and then the speed was adjusted to 600p / min for grinding for 5h.

[0053] (2) aluminum powder and LiNi after grinding activation in step (1) 0.333 co 0.333 mn 0.333 o 2 The positive electrode material mixture was added into a three-necked flask containing 100 mL of LiOH solution with a concentration of 2 mol / L, and stirred and reacted at 80° C. for 5 h.

[0054] (3) Wash the precipitate obtained in step (2) with deionized water for 3 times, then wash with absolute ethanol for 3 times, then filter, and keep the filter cake in a blast oven at 80°C for 12 hours to obtain xLi + ·Al(OH) 3 ·yH 2 The precursor of O-coated cathode materials.

[0055] (4) Put the precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com