Transparent packaging tin bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

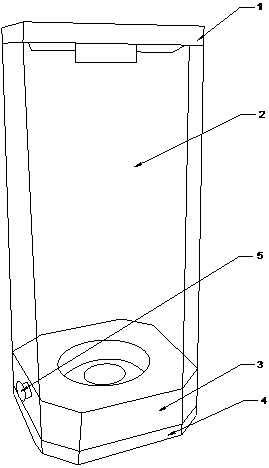

[0010] see figure 1 , a tinplate transparent packaging barrel, comprising a top cover 1, a transparent barrel body 2, a base 3 and a bottom plate 4, the transparent barrel body 2 is located between the upper cover 1 and the base 3, and the upper cover 1 is made of tinplate material, so The upper cover is located on the upper side of the transparent barrel body 2 , the base 3 is located on the lower side of the transparent barrel body 2 , and the base 3 is installed above the base 4 through snap buttons 5 .

[0011] In the present invention, both the upper cover 1 and the base 3 are made of tinplate material, which has no harm to the human body during the production process and has no impact on environmental pollution. The high-tech in-mold injection molding process is used to closely combine the plastic parts and the tinplate. The parts are wrappe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com