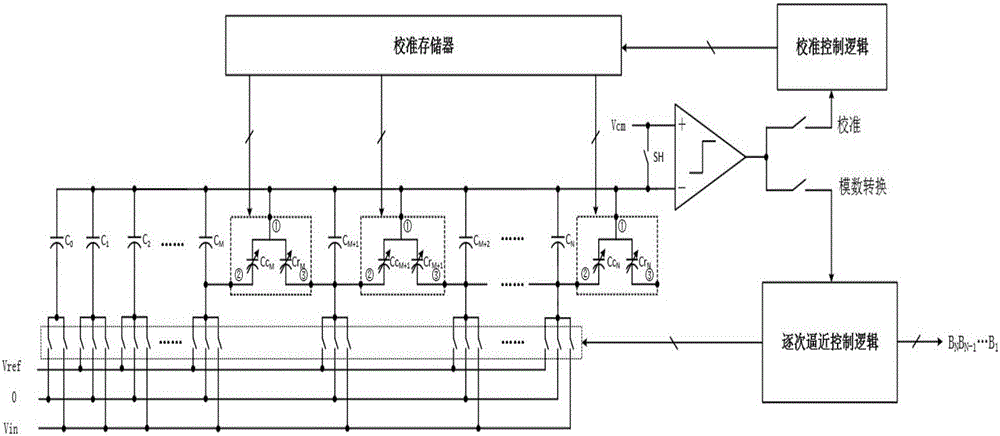

Novel high-precision capacitor self-calibration analog-to-digital converter of successive approximation type

An analog-to-digital converter and successive approximation technology, applied in the field of microelectronics, can solve the problems of high cost of laser correction technology, inaccurate calibration parameters, and mechanical stress effects, and achieve the effects of reducing errors, reducing power consumption, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below through embodiments.

[0026] The high-precision SAR ADC in the present invention has two working modes: a self-calibration mode and an analog-to-digital conversion mode, and the two working modes share a comparator.

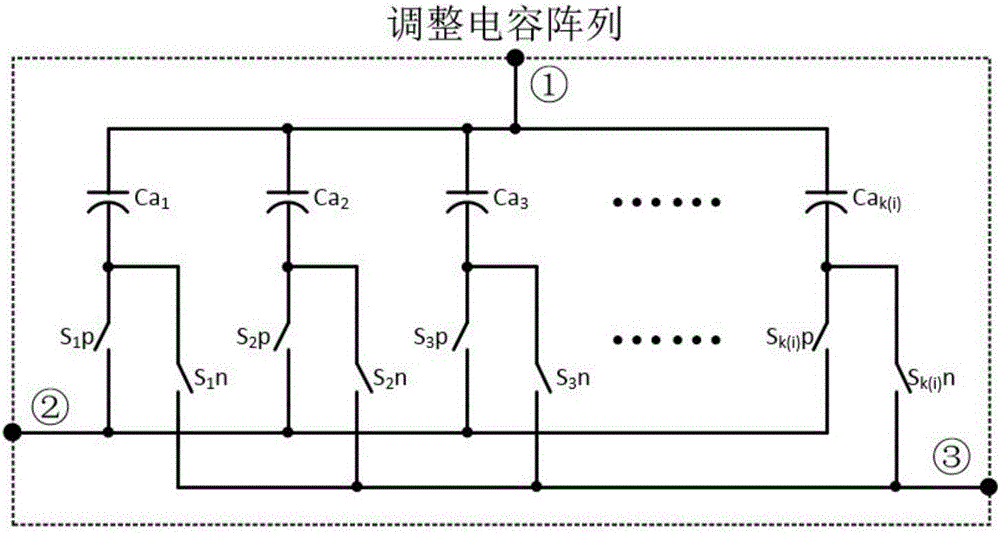

[0027] The self-calibration working mode of the high-precision SAR ADC can be divided into two stages, which are reset stage and adjustment stage. During the reset phase, the sampling switch SH is closed to eliminate the offset error at the comparator input. Then enter the adjustment stage: disconnect the sampling switch SH. Determine the sampling capacitor C to be adjusted i , sampling capacitor C from the lowest bit to be adjusted M start. Initialize the sampling capacitor C to be adjusted i The adjustment capacitor array, select a part of the capacitor as the compensation capacitor Cc i connected to C i Middle; use the comparator and switch timing to compare the size of the sum of the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com