Ultra-small coreless brushless high-efficiency hub motor

An in-wheel motor, ironless technology, used in motors, electromechanical devices, electric vehicles, etc., can solve the problems of low motor speed, fast gear wear, small wheel hub, etc., and achieve extended gear life, high transmission efficiency, and coil loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

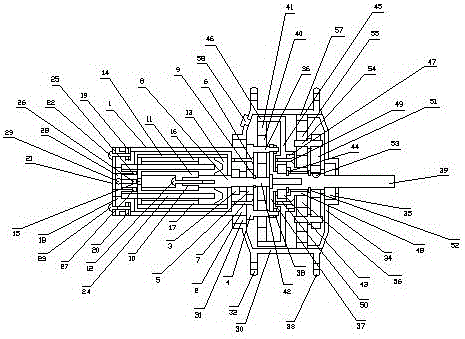

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0011] exist figure 1In the front view sectional structure schematic diagram of the ultra-small ironless brushless high-efficiency hub motor shown, the hub motor is a kind of ironless brushless two-pole permanent magnet DC motor, which is also the left half shaft of the hub, and the hub motor is set Aluminum alloy shell 1, the right end of the aluminum alloy shell is made with the right end cover 2 integrated with the shell, the left end of the right end cover is provided with a bearing frame, the inner circle of the bearing frame is installed with the left bearing 3, the right end of the right end cover is provided with a circular plate frame 4, and the center of the circular plate frame is installed Right bearing 5, the upper and lower countersunk head screws 6 and 7 on the disc frame are screwed in the upper and lower nut holes of the right end cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com