Production method of bipolar membrane electrode

A bipolar membrane and electrode technology, which is applied in the field of low-cost integrated bipolar membrane electrode preparation, can solve difficult problems such as flexible control of proton exchange layer thickness, low integration of fuel cell preparation process, and increased overall system complexity, etc. problems, to achieve lower fixed and variable costs, increased production flexibility, and improved membrane electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of integrated bipolar membrane electrode provided by the present invention, its specific process steps are as follows:

[0031] 1) Preparation of cation exchange resin solution: Mix cation exchange resin material and solvent, dissolve at 100-400°C high temperature to form a uniformly dispersed cation exchange resin solution, wherein, cation exchange resin material:solvent=1:(5-500 ); the cation exchange resin is: perfluorosulfonic acid polymer resin, acid-doped polybenzimidazole polymer resin, etc.

[0032] 2) Preparation of the anode catalyst slurry: the anode catalyst, the cation exchange resin solution and the dispersant are mixed, and after ultrasonic vibration, a uniformly dispersed catalyst slurry is formed. Wherein catalyzer: cation exchange resin solution: dispersant=1: (1-100): (1-300); Described catalyzer is Pt, Ru, Ir, Au, Ni, Co, Zn, Ag or their alloys and oxide.

[0033] 3) Pretreatment of the polymer framework material: soak ...

Embodiment 1

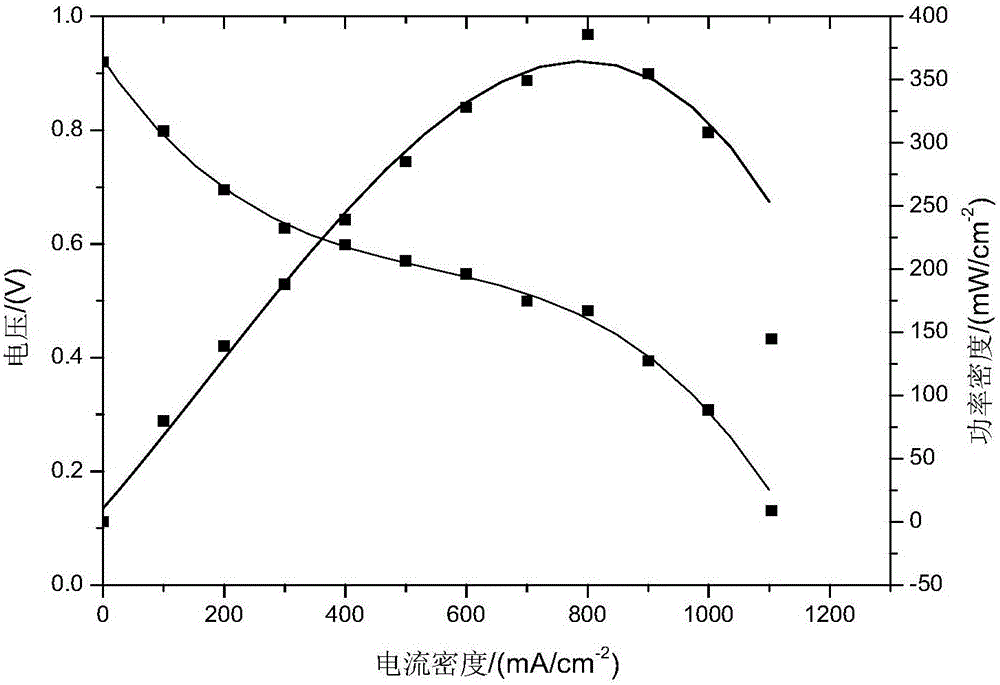

[0043]The perfluorosulfonic acid resin material and the solvent are mixed according to the mass ratio of 1:100, and dissolved at a high temperature of 400°C to form a uniformly dispersed polymer electrolyte slurry. The solvent was prepared according to the mass ratio of isopropanol:water 3:1. Take a part of the polymer electrolyte slurry according to the Pt / C (40%) catalyst:polymer electrolyte slurry:isopropanol mass ratio of 1:10:500, and ultrasonically vibrate for 30 minutes to form a uniform catalyst slurry. Take a 15-micron thick ePTFE membrane as the base frame material, soak it in boiling methanol for half an hour, then soak it in isopropanol solution for 24 hours, and then take it out and spread it on the heating substrate and heat it to 120 degrees. Spray polymer electrolyte slurry on ePTFE to form a viscous proton exchange layer. Next, the catalyst slurry is sprayed on the side of the proton exchange layer to form a tightly bonded anode catalyst layer, and after cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com