A fingerprint recognition module and preparation method thereof

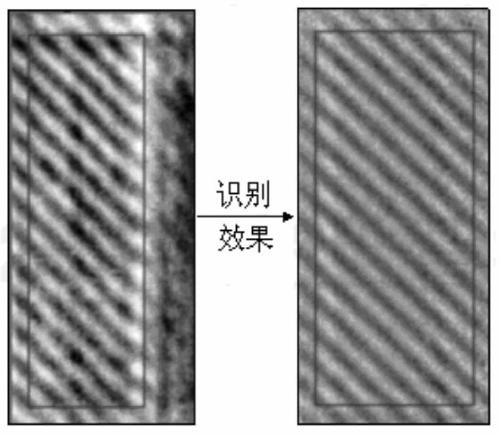

A fingerprint recognition module and speed control technology, which is applied in character and pattern recognition, fingerprint/palmprint acquisition/organization, print image collection, etc., can solve problems such as difficult color matching, easy scratches, and low surface hardness cost, solve the effect of easy falling off, and improve the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

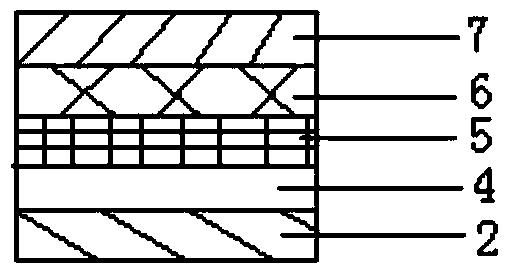

[0043] A. Use the UV wire drawing process to form the required texture on the glass surface: use the graphic transfer technology to form a 10μm wire drawing texture on the surface of the glass substrate (550mm*650mm, 0.2mm thickness), the specific steps:

[0044] 1) The UV glue is evenly distributed on the drawing template in a straight line, and the starting point is aligned with the left and right sides of the mold;

[0045] 2) The automatic UV film of the machine is used for UV glue pressing operation, the roller pressure is 0.4MPa, and the speed is 60mm / s;

[0046] 3) UV exposure curing, UV energy 2000mj / cm 2 ;

[0047] B. Using NCVM technology (non-conductive metal coating technology), a non-conductive metal film (such as silicon with a thickness of about 5 nanometers) is formed on the surface of the UV layer of the plain glass substrate;

[0048] C. By controlling the cutting depth and speed of the cutter wheel or controlling the energy and speed of the laser engraving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com