A light-emitting component with reflection and current blocking characteristics and a manufacture method thereof

A technology for light-emitting components and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of not considering the loss of external quantum efficiency, increasing equipment costs and production costs, and complicating the process, so as to achieve increased adhesion , high reliability, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

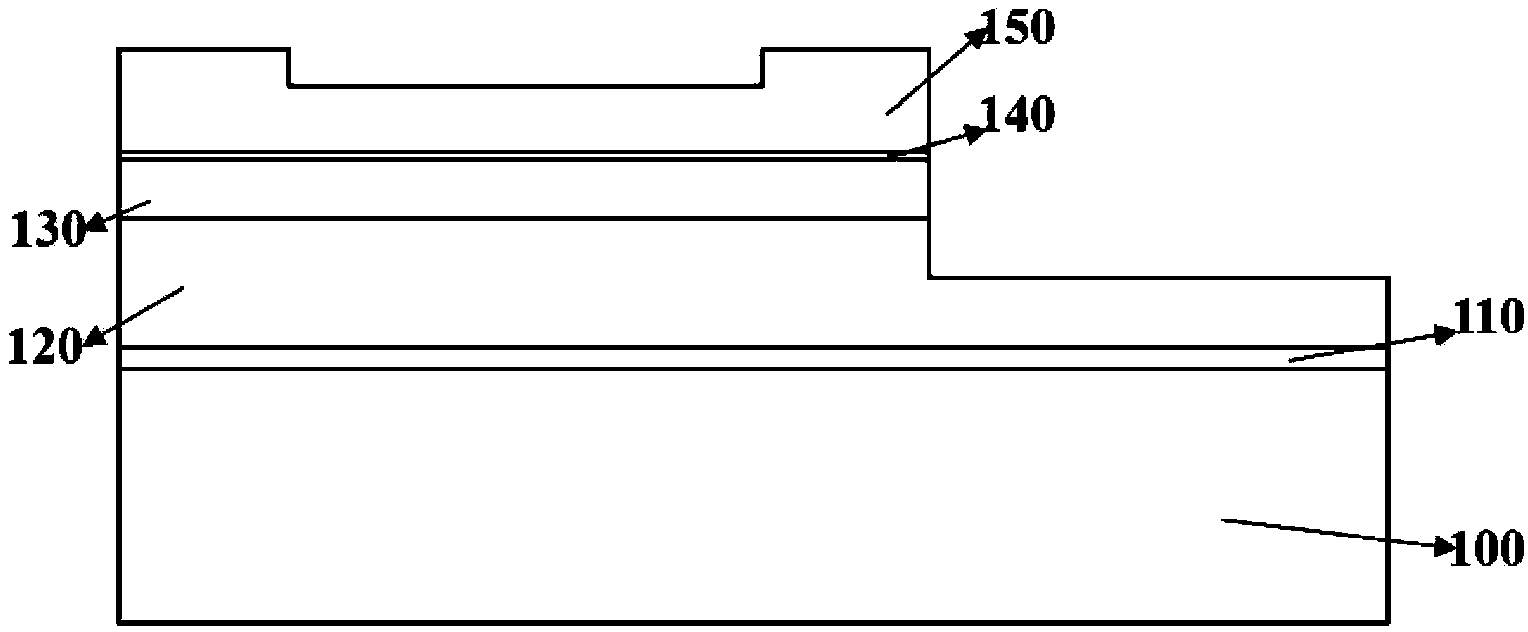

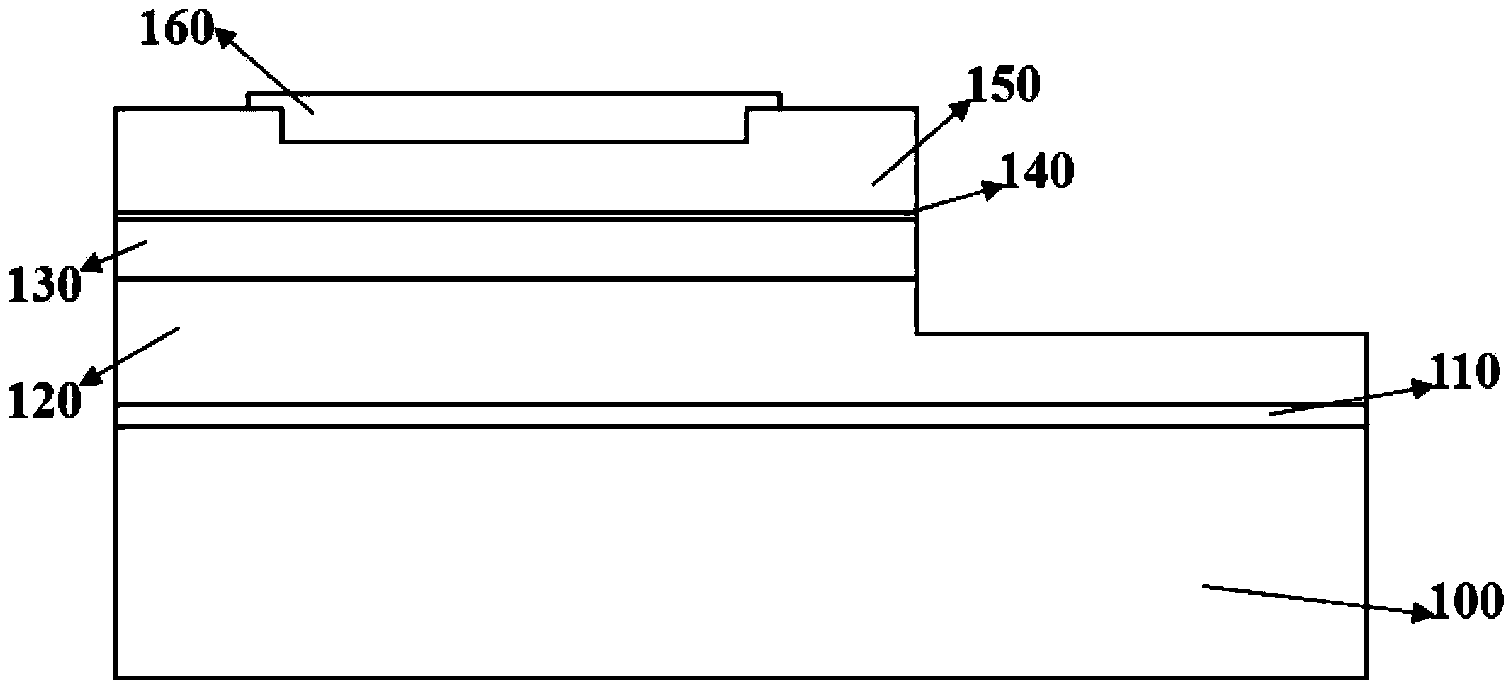

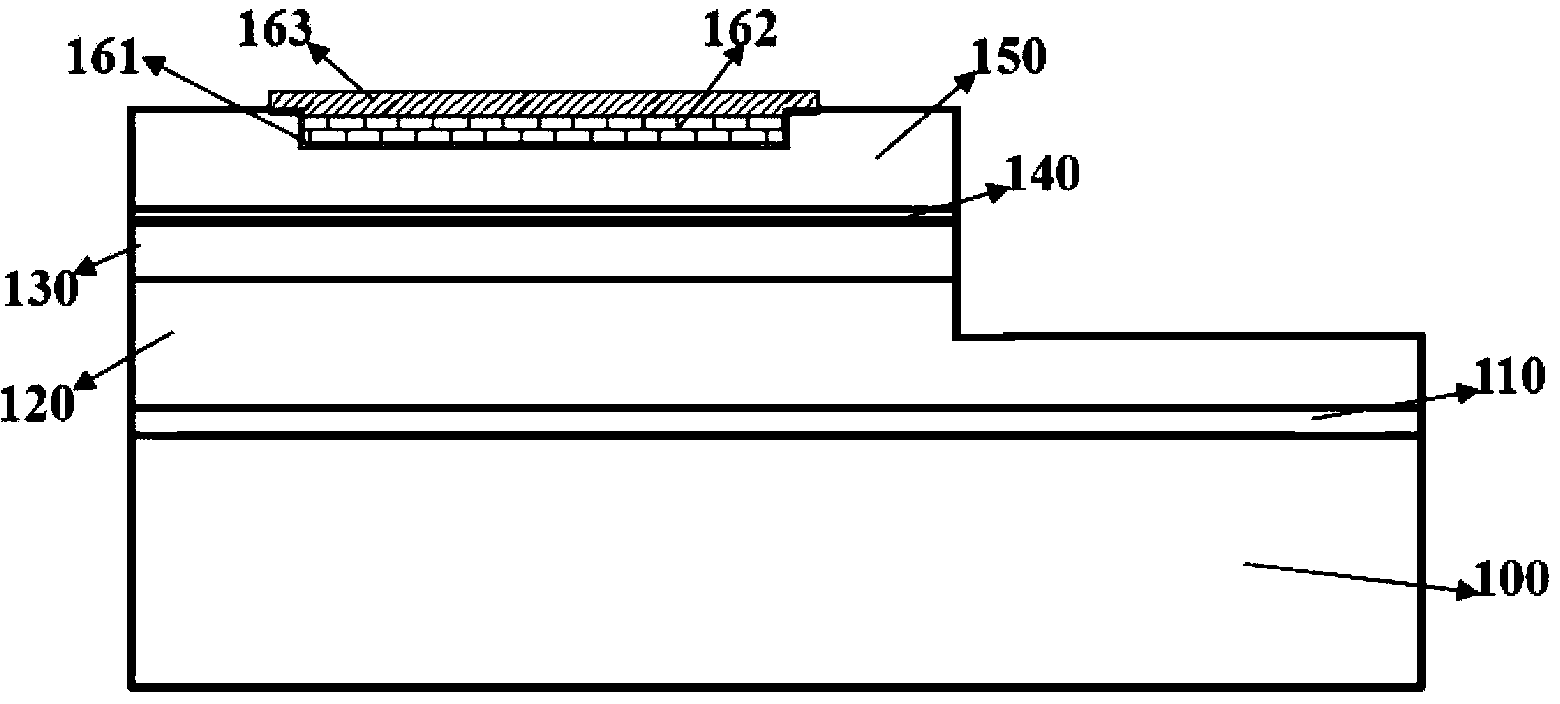

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] According to one embodiment of the present invention, there is provided a light emitting element having reflective and current blocking properties. For gallium nitride-based light-emitting devices, in order to reduce the light emitted by the active layer from being absorbed by the pad to the metal electrode, one way is to introduce a metal reflective layer between the metal electrode and the p-type gallium nitride epitaxial layer , such as silver or aluminum reflective layers. However, direct contact between silver and aluminum and the p-type gallium nitride epitaxial layer is not strong, and the phenomenon of electrode detachment is prone to occur, thus hindering the application of metal reflective electrodes. However, this embodiment overcomes the above-mentioned problems.

[0045] The preparation steps of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com