Method for acoustically monitoring blockage of gas extraction pipeline

A gas drainage and sound wave technology is applied in the field of monitoring gas drainage pipeline blockage, which can solve the problems of being unsuitable for underground iron gas drainage pipelines, unable to accurately locate clogging points, and low on-site practicability, and achieve high on-site practicality. Value, improving gas extraction efficiency, and high on-site practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

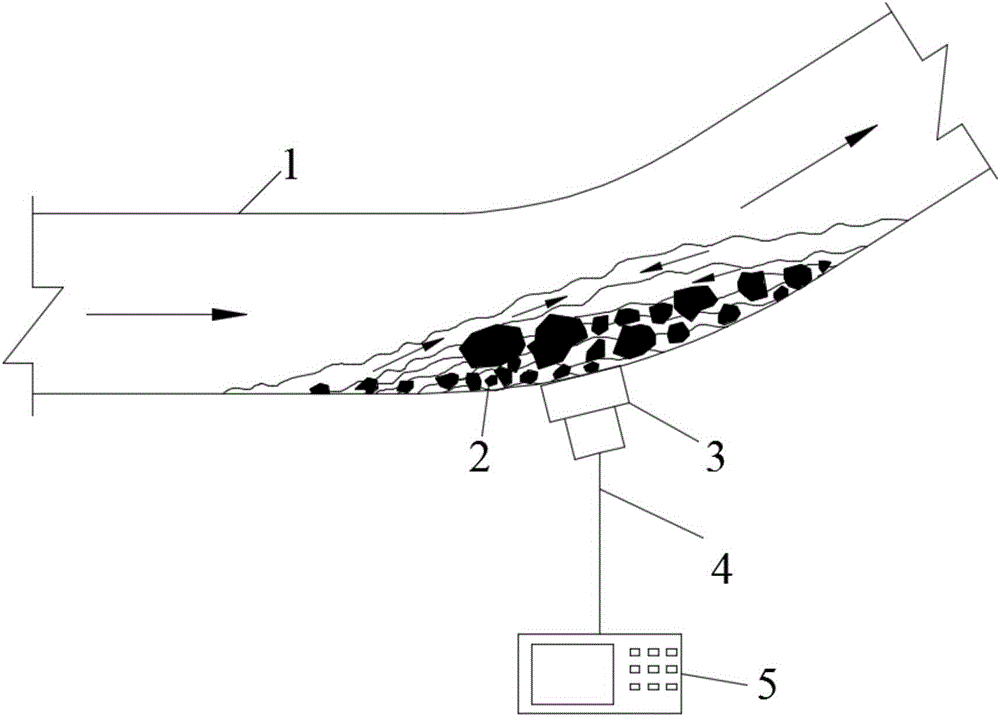

[0026] Such as figure 1 As shown, a method for sonic monitoring of gas drainage pipeline clogging comprises the following steps:

[0027] a. Place the acoustic wave sensor 3 at point A on the wall of the gas drainage pipe 1 to receive the acoustic signals of accumulated water in the pipe and the friction between cinder 2 and the pipe wall, and analyze and process the intensity of the acoustic wave signal by monitoring the host computer 5; the point A is set In the curved section of the gas drainage pipe 1;

[0028] b. Set monitoring point B on the pipe wall at a distance of 3-5m from point A to monitor the acoustic signal strength at point B; the point B is set on the side of point A along the gas flow direction;

[0029] c. If the acoustic signal strength value at point B is greater than that at point A, set monitoring point C in the direction from point A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com