Method and device for measuring diesel injector needle valve movement rule of diesel engine based on visualization method

A motion law, diesel engine technology, used in measuring devices, fuel injection devices, machines/engines, etc., can solve problems such as inability to measure the eccentric movement of needle valves and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

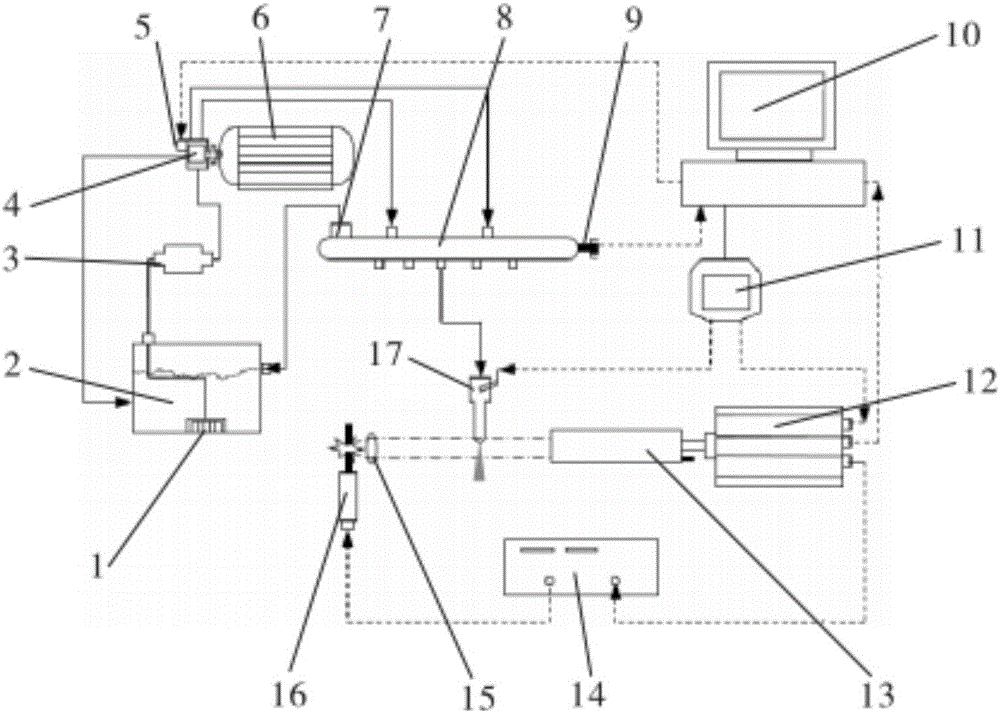

[0020] A device for measuring the movement law of the needle valve of a diesel engine injector, including two parts: a high-pressure common rail injection system and a data acquisition system;

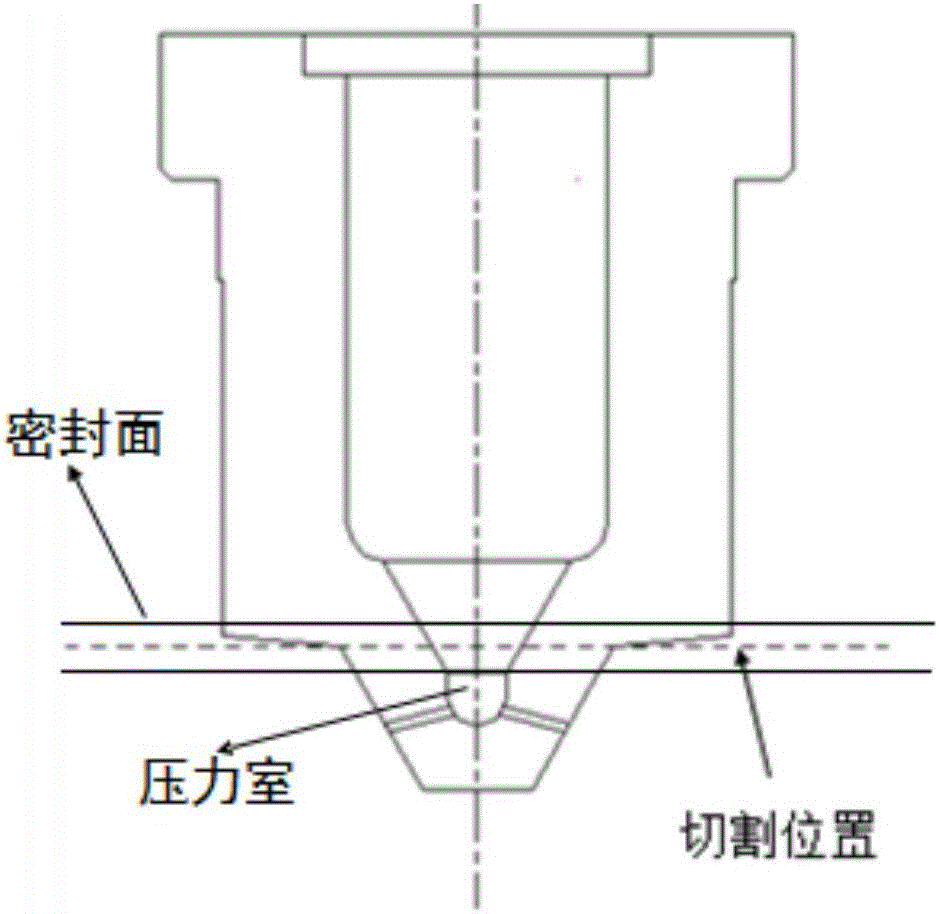

[0021] The high pressure common rail injection system includes diesel filter fuel tank 1, fuel tank 2, low pressure fuel pump 3, high pressure fuel pump 4, fuel metering valve 5, variable frequency motor 6, pressure relief valve 7, common rail pipe 8, and common rail pressure sensor 9. Control computer 10, electronically controlled fuel injector 17 with transparent head;

[0022] The data acquisition system includes a synchronization and delay controller 11, a high-speed camera 12, a microscope lens 13, a nanosecond flash controller 14, a convex lens 15, and a nanosecond flash 16.

[0023] Further, the fuel tank 1 of the diesel filter placed in the fuel tank 2 is connected to the low-pressure fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com