High-strength urban underground comprehensive pipe gallery

A comprehensive pipe gallery and high-strength technology, applied to underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of low space utilization, plate arc deformation, and weak price advantage, and achieve the ability to resist uneven settlement Improved performance, improved dynamic load resistance, and improved structural cracking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

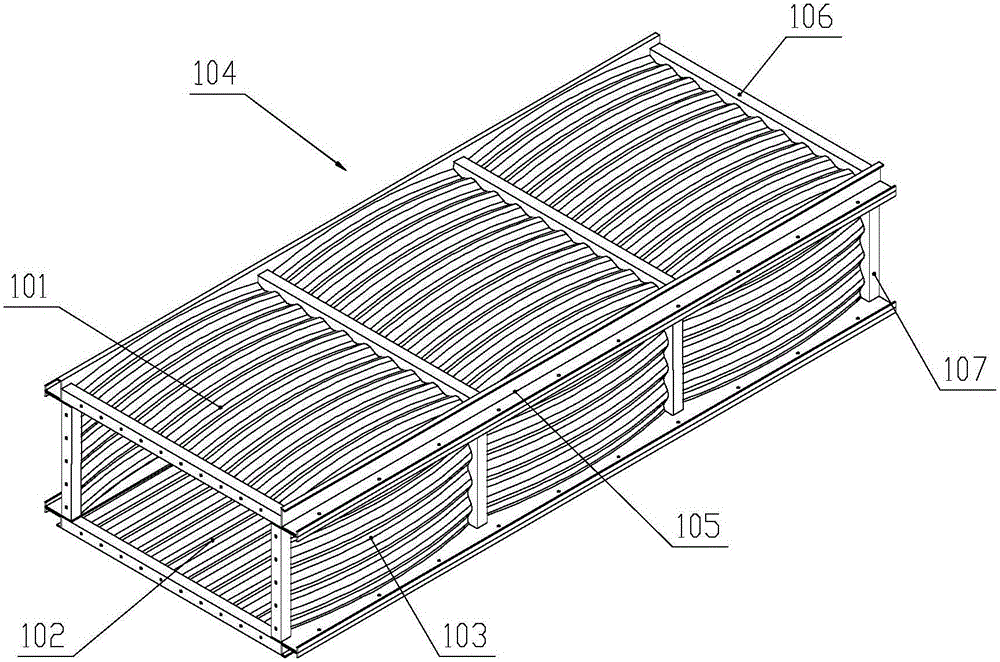

[0050] Such as figure 1 As shown, a high-strength urban underground comprehensive pipe gallery of the present invention includes a box-shaped pipe joint 104 assembled from a top plate 101, a bottom plate 102, and two side plates 103. Specifically, welding, flange connection or hidden bolt connection can be used. connection method. The box-shaped pipe joint 104 is rectangular. At the same time, the box-shaped pipe joint 104 can be as long as 15 to 25 meters. As long as the transportation conditions permit, the length can be longer, so that the joints of the entire pipe gallery are reduced and the sealing performance is better; the obtained box The pipe joints 104 are assembled in the axial direction to form a high-strength urban underground comprehensive pipe gallery 100, and adjacent box-shaped pipe joints 104 are connected by welding, flange connection or hidden bolts.

[0051] The top board 101 , bottom board 102 and side boards 103 are corrugated boards with protrusions on...

Embodiment 2

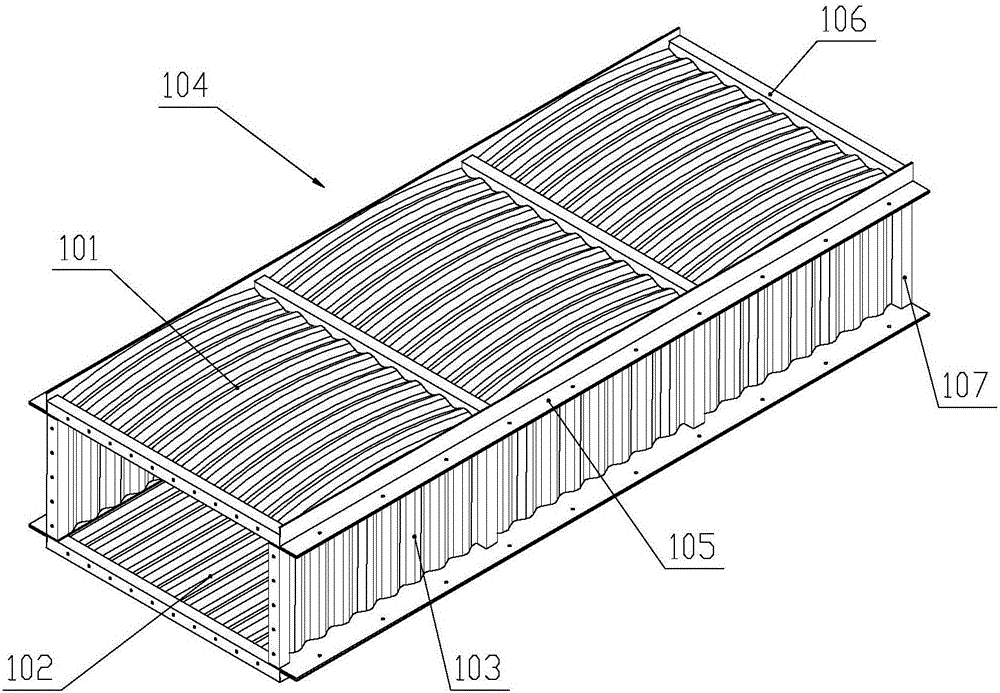

[0060] Such as figure 2 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1, the difference is that: the side plate 103 is a straight corrugated plate, and the direction of the arched pattern is consistent with the extending direction of the column. The corrugated steel web bridge principle is used for the side panels whose pattern direction is consistent with the direction of the column in the comprehensive pipe corridor. The pressure has been greatly increased.

Embodiment 3

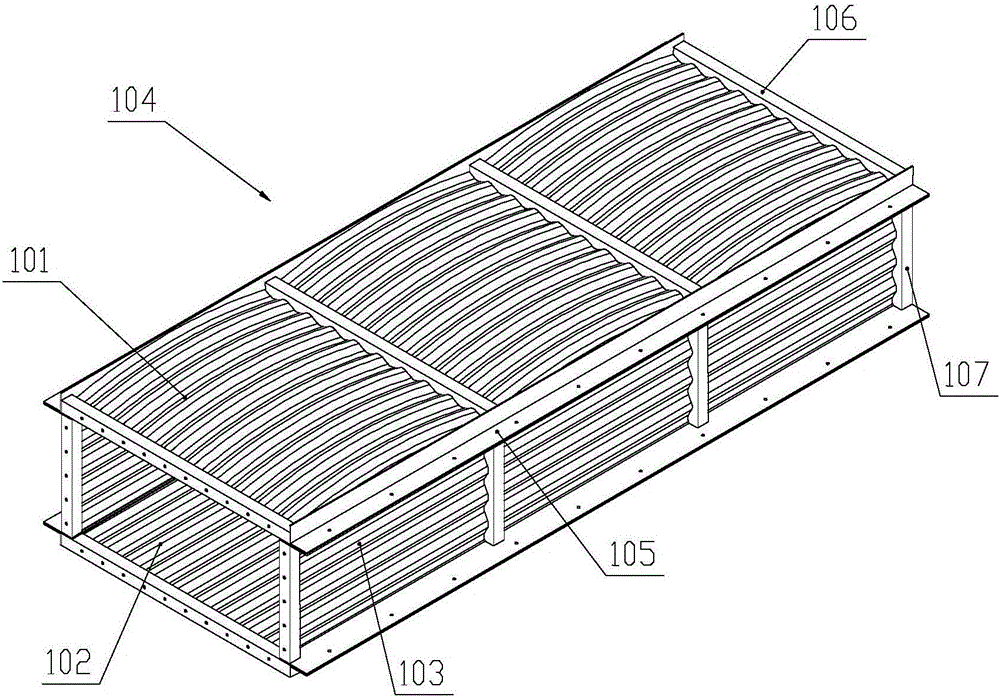

[0062] Such as image 3 As shown, the structure of embodiment 3 is basically the same as that of embodiment 1, the difference is that the side plate 103 is a straight corrugated plate, and the direction of its arching pattern is consistent with the extending direction of the pipe gallery. The plate with protrusions adopts the principle of large moment of inertia. The principle of large moment of inertia is to form a straight plate into a plate with a raised structure in section, so that its section moment of inertia is greatly improved, and it is resistant to bending, torsion and deformation. The capacity is significantly improved, and then the load-carrying capacity of the plate is greatly improved compared with the flat plate, and the degree of performance improvement depends on the shape and size of the protrusions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com