Oiling method for para-aramid fibers

A technology of para-aramid fiber and oiling agent is applied in the field of oiling para-aramid fiber, which can solve the problems of few active groups and weak binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

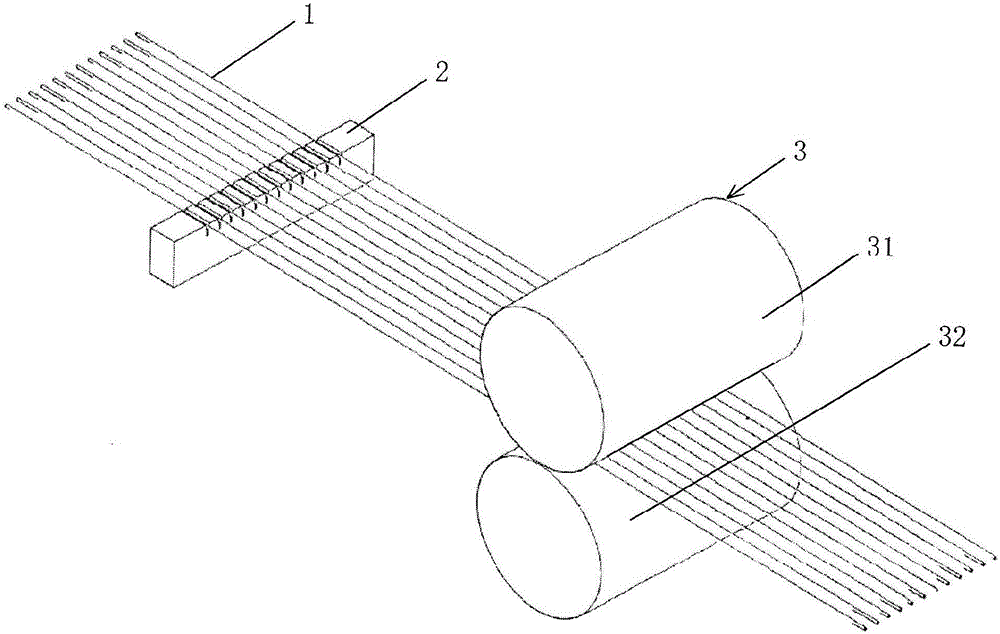

[0025] Please combine figure 1 .

[0026] A) Oiling, heating the oil in the oil tank (not shown in the figure) to 60°C (the oil tank is equipped with heating elements such as electric heating pipes) to improve the fluidity of the oil After spinning, washing, neutralizing, and drying, the para-aramid fiber tow 1 with a denier of 200D and a moisture content of 7% passes through the corresponding oil tank and is equipped with a traveling speed of 400m / min. The oiling device 2 of the nozzles with the same number of para-aramid fiber tows 1, each of the para-aramid fiber tows 1 corresponds to a nozzle, and the nozzle ( That is, the oiling nozzle, the same below) oiling the para-aramid fiber tow 1 to obtain the oiled para-aramid fiber tow;

[0027] B) Infiltration of the oiling agent. After the oiled para-aramid fiber tow in step A) goes out of the oiling device 2, it enters the work roll 31 of the roller extrusion device 3 at a traveling speed of 400m / min Between it and the supportin...

Embodiment 2

[0029] Please combine figure 1 .

[0030] A) Oiling, heating the oil in the oil tank (not shown in the figure) to 80°C (the oil tank is equipped with heating elements such as electric heating tubes) to improve the fluidity of the oil After spinning, washing, neutralizing, and drying, the para-aramid fiber tow 1 with a fineness of 300D and a moisture content of 10% passes through the corresponding oil tank and is equipped with a traveling speed of 600m / min. The oiling device 2 of the nozzles with the same number of para-aramid fiber tows 1, each of the para-aramid fiber tows 1 corresponds to a nozzle, and the nozzle is used to control the flow of the oil in the state of the oil metering pump. The para-aramid fiber tow 1 is oiled to obtain the para-aramid fiber tow after oiling;

[0031] B) Infiltration of the oiling agent. After the oiled para-aramid fiber tow in step A) travels out of the oiling device 2, it enters the work roll 31 of the roll extrusion device 3 at a traveling sp...

Embodiment 3

[0033] Please combine figure 1 .

[0034] A) Oiling, heating the oil in the oil tank (not shown in the figure) to 70℃ (the oil tank is equipped with heating elements such as electric heating pipes) to improve the fluidity of the oil After spinning, washing, neutralizing, and drying, the para-aramid fiber tow 1 with a fineness of 1500D and a moisture content of 10% passes through the corresponding oil tank and is equipped with a traveling speed of 1000m / min. The oiling device 2 of the nozzles with the same number of para-aramid fiber tows 1, each of the para-aramid fiber tows 1 corresponds to a nozzle, and the nozzle is used to control the flow of the oil by the oil metering pump. The para-aramid fiber tow 1 is oiled to obtain the para-aramid fiber tow after oiling;

[0035] B) Infiltration of the oiling agent. After the oiled para-aramid fiber tow in step A) travels out of the oiling device 2, it enters the work roll 31 of the roller extrusion device 3 at a traveling speed of 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com