Preparation method for MnO2/C composite fibres

A composite fiber and hybrid fiber technology, which is applied in fiber processing, fiber chemical characteristics, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as application limitations and poor conductivity, and achieve simple preparation methods, high specific capacitance, and surface distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

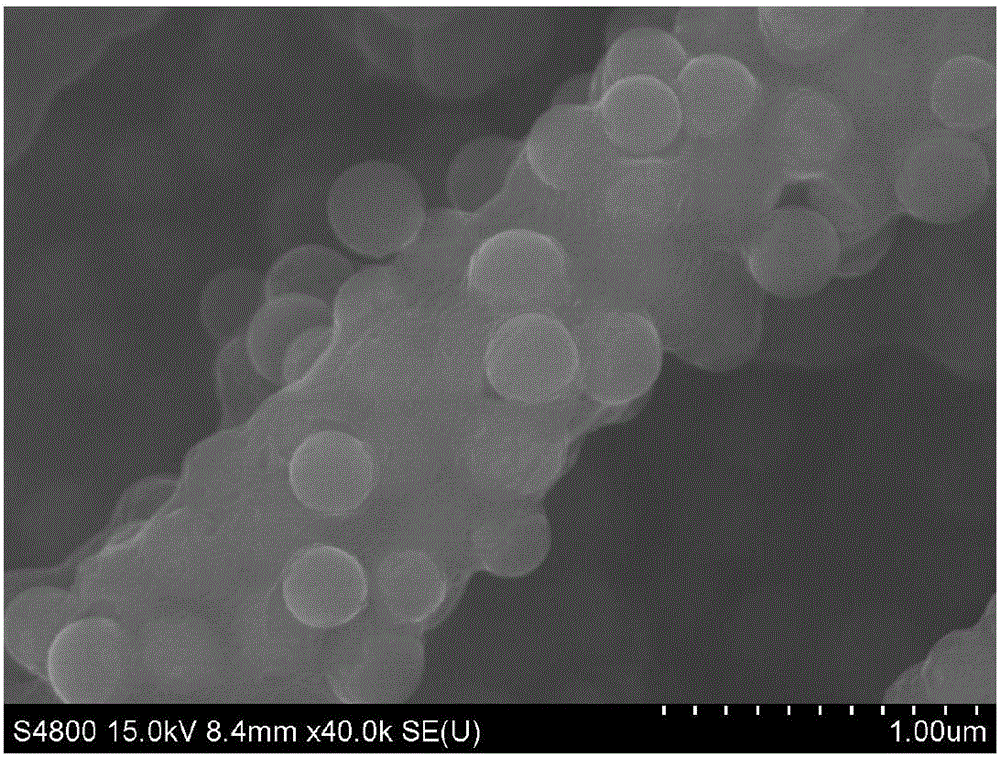

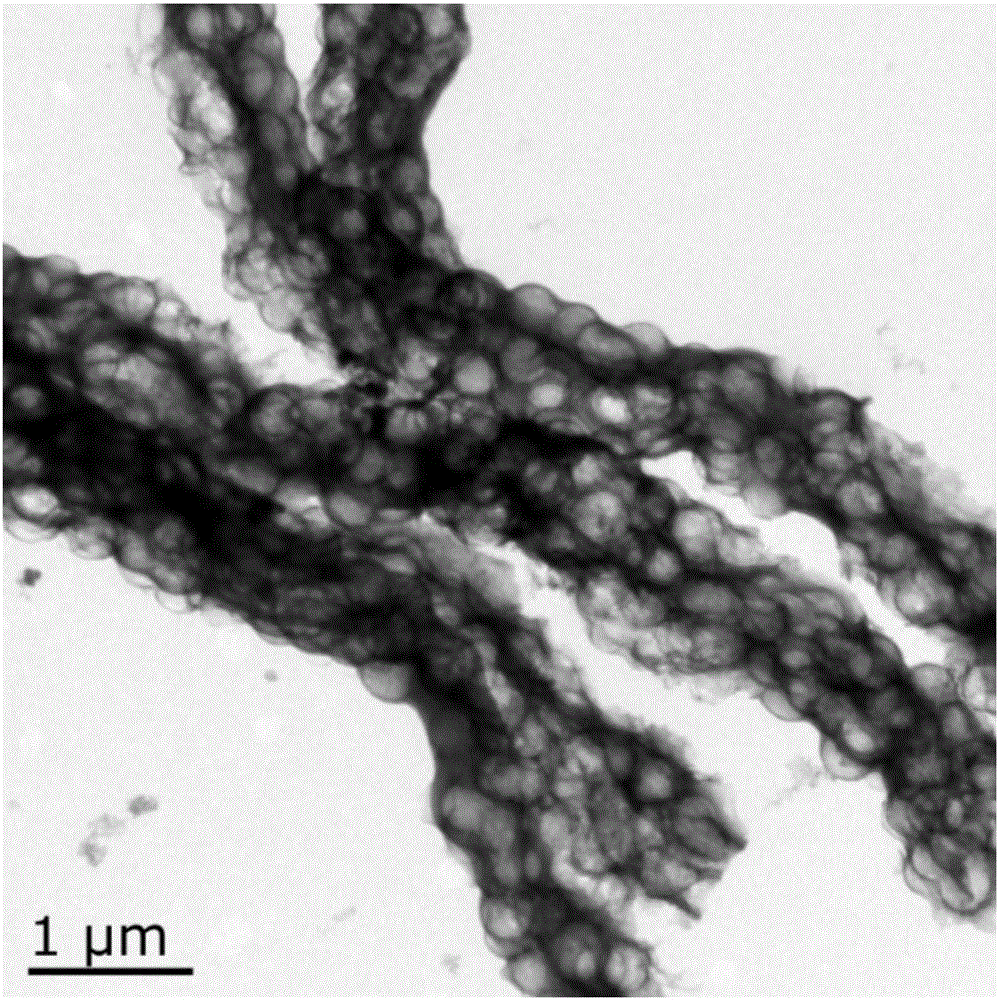

Image

Examples

Embodiment 1

[0028] 1. Preparation of SiO 2 / PAN / PVP mixed fiber: Dissolve 0.76g PVP in 4mL DMF solution and stir until uniform. 1.52g of SiO 2 Add to 4mL DMF solution, ultrasonic for 1h to make SiO 2 Disperse evenly, add it to PVP DMF (4mL) solution, stir and mix well. Add 0.76g PAN to the above mixture in portions and stir for 4-5h until a transparent colloid is formed. The above mixture was injected into a 10 mL syringe equipped with a needle with an inner diameter of 6 mm and placed on an electrospinning machine with a voltage of 15 kV, a distance of 15 cm between the needle and the receiving plate, and a spray speed of 0.2 mm / min for electrostatic spinning.

[0029] 2. Preparation of SiO 2 / C fiber: take the SiO prepared above 2 The / PAN / PVP mixed fiber was placed in a vacuum tube furnace, and nitrogen was introduced for 20 minutes in advance, and a heating program was set to 1°C / min to 250°C for 1 hour, and 5°C / min to 800°C for 2 hours to obtain a black fiber membrane.

[0030] 3. Prepar...

Embodiment 2

[0033] 1. Preparation of SiO 2 / PAN / PVP mixed fiber: Dissolve 0.76g PVP in DMF solution and stir until uniform. 1.52g of SiO 2 Add to 4mL DMF solution, ultrasonic for 1h to make SiO 2 Disperse evenly, add it to PVP DMF (4mL) solution, stir and mix well. Add 0.76g PAN to the above mixture in portions and stir for 4-5h until a transparent colloid is formed. The above mixture was injected into a 10 mL syringe equipped with a needle with an inner diameter of 6 mm and placed on an electrospinning machine with a voltage of 15 kV, a distance of 15 cm between the needle and the receiving plate, and a spray speed of 0.2 mm / min for electrospinning.

[0034] 2. Preparation of SiO 2 / C fiber: take the SiO prepared above 2 The / PAN / PVP mixed fiber was placed in a vacuum tube furnace, and nitrogen was introduced for 20 minutes in advance, and a heating program was set to 1°C / min to 250°C for 1 hour, and 5°C / min to 800°C for 2 hours to obtain a black fiber membrane.

[0035] 3. Preparation of ni...

Embodiment 3

[0038] 1. Preparation of SiO 2 / PAN / PVP mixed fiber: Dissolve 0.76g PVP in DMF solution and stir until uniform. 1.52g of SiO 2 Add to 4mL DMF solution, ultrasonic for 1h to make SiO 2 Disperse evenly, add it to PVP DMF (4mL) solution, stir and mix well. Add 0.76g PAN to the above mixture in portions and stir for 4-5h until a transparent colloid is formed. The above mixture was injected into a 10 mL syringe equipped with a needle with an inner diameter of 6 mm and placed on an electrospinning machine with a voltage of 15 kV, a distance of 15 cm between the needle and the receiving plate, and a spray speed of 0.2 mm / min for electrospinning.

[0039] 2. Preparation of SiO 2 / C fiber: take the SiO prepared above 2 The / PAN / PVP mixed fiber was placed in a vacuum tube furnace, and nitrogen was introduced for 20 minutes in advance, and a heating program was set to 1°C / min to 250°C for 1 hour, and 5°C / min to 800°C for 2 hours to obtain a black fiber membrane.

[0040] 3. Preparation of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com