Method for preparing sheet-shaped nanometer Mg(OH)2 by using electrolyte diaphragm discharge plasma

A diaphragm discharge and electrolyte technology, applied in the field of preparation of flake nano-Mg2, can solve the problems of complicated preparation process and harsh conditions, and achieve the effect of simple equipment, controllable process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Treatment of magnesium bars: Take a piece of high-purity magnesium sheet with a size of 3 mm × 20 mm × 1.5 mm, smooth it with water sandpaper, polish it, soak it in acetone for 1 h, and then ultrasonically wash it in ethanol and deionized water for 10 minutes, respectively. min, to remove the grease on the surface, and use the magnesium sheet as the anode.

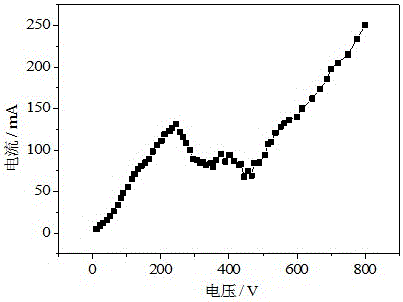

[0035] (2) Installation of diaphragm discharge device: take 250 mL temperature-controlled reactor 1, add 200 mL 2g / L sodium sulfate solution into the reactor as electrolyte 2, insert a graphite carbon rod with a diameter of 5 mm in the electrolyte as The cathode rod 3 (the depth inserted into the electrolyte is 1.5 cm) and the quartz tube 4, the anode magnesium piece 5 is placed in the quartz tube 4, and a small hole with a diameter of 0.5 mm is opened on the quartz tube 4 at a distance of 1 cm from the bottom of the quartz tube. Hole 6; make the anode and cathode electrolytes connected through this small hole. ...

Embodiment 2

[0038] (1) The processing of magnesium bar: with embodiment 1;

[0039] (2) Installation of the diaphragm discharge device: same as in Example 1;

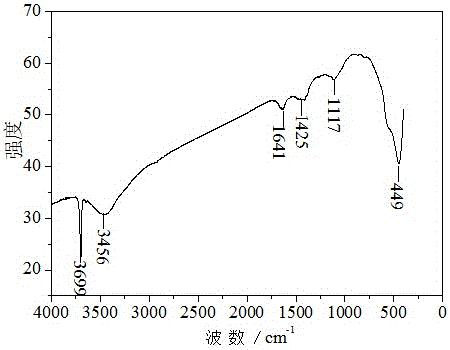

[0040] (3) Nanosheet Mg(OH) 2 Preparation: control the discharge voltage at 700 V, after continuous discharge for 2 h, white Mg(OH) 2 Turbid liquid; the Mg(OH) 2 After the turbid liquid was ultrasonically dispersed for 10 min, it was centrifuged at a speed of 10000 r / min, washed several times with distilled water to remove the electrolyte sodium sulfate, washed several times with absolute ethanol, and centrifuged. Vacuum dry at 60°C to constant weight and grind to obtain nanometer Mg(OH) 2 , the scanning electron microscope results are shown in Figure 5 b. For the uniformity of the solution, the solution was continuously stirred at 120 r / min.

Embodiment 3

[0042] (1) The processing of magnesium bar: with embodiment 1;

[0043] (2) Installation of the diaphragm discharge instrument: same as in Example 1;

[0044] (3) Nanosheet Mg(OH) 2 Preparation: control the discharge voltage at 750 V, and after continuous discharge for 3 hours, white Mg(OH) 2 Turbid liquid; the Mg(OH) 2 After the turbid liquid was ultrasonically dispersed for 10 min, it was centrifuged at a speed of 10000 r / min, washed several times with distilled water to remove the electrolyte sodium sulfate, washed several times with absolute ethanol, and centrifuged. Vacuum-dry at 70°C to constant weight and grind to obtain nano-Mg(OH) 2 , the scanning electron microscope results are shown in Figure 5 c. For the uniformity of the solution, the solution was continuously stirred at 140 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com