Metal film etching liquid and method for etching printed circuit board

A technology for printed circuit boards and metal films, which is applied to printed circuits, printed circuit manufacturing, and removal of conductive materials by chemical/electrolytic methods. Etching speed is fast and the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

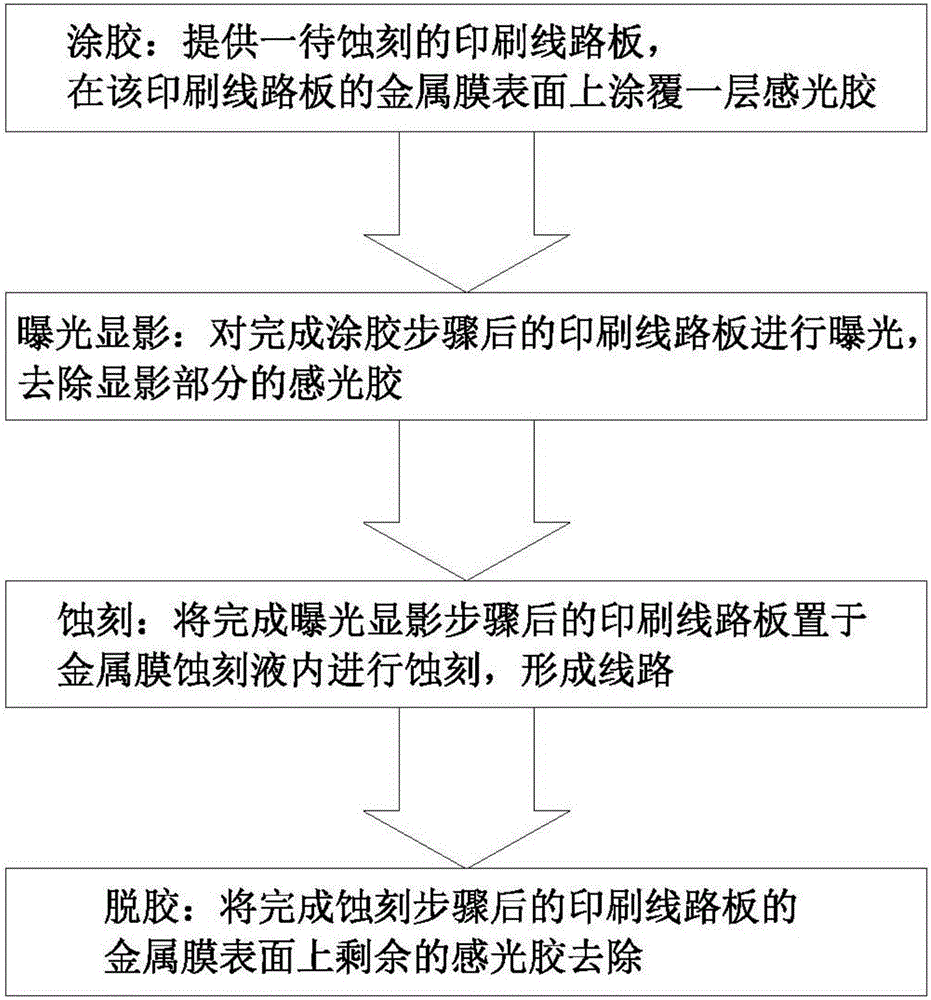

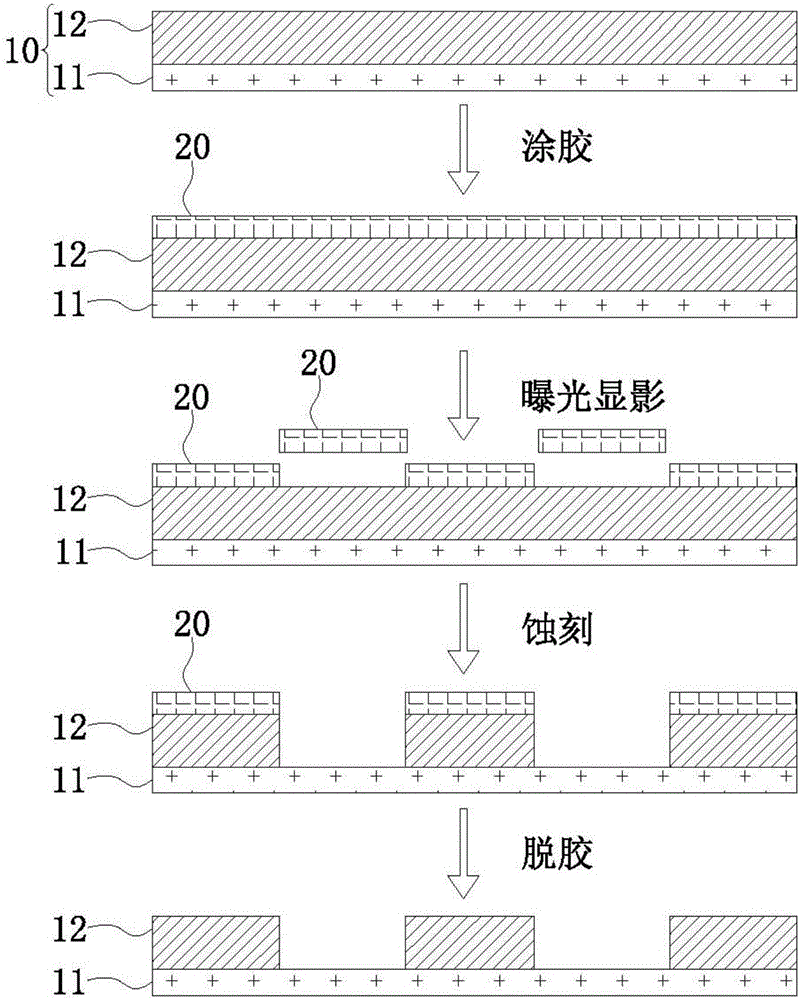

Method used

Image

Examples

Embodiment 1

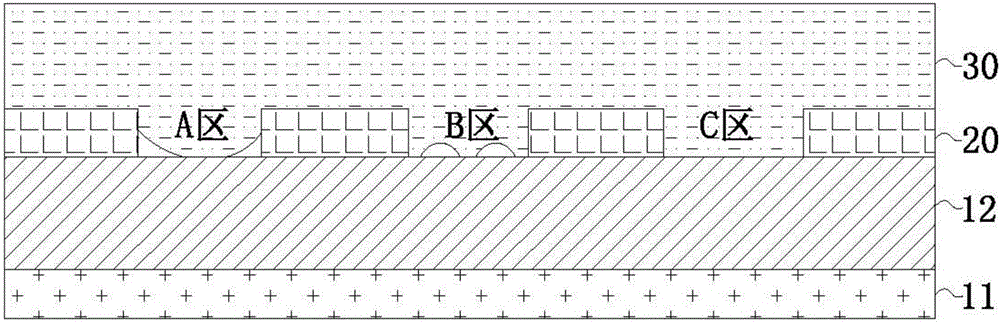

[0074] The mass percent of each component of the metal film etching solution 30 is: 3% FeCl 3 , 4% HCl, 0.5% NaClO 3 , 0.001% surfactant and the balance water, and the surface tension is 30mN / m, the pH is 5.8, and the temperature is 38°C. The mass ratio of the metal in the etched metal film 12 is 90% copper and 10% nickel, and the etching time is 150s. After the etching is completed, the width difference between the lines is within 5 μm, which meets the process requirements.

Embodiment 2

[0076] The mass percent of each component of the metal film etching solution 30 is: 16% FeCl 3 , 17% HCl, 3.12% NaClO 3 , 0.18% surfactant and the balance water, and the surface tension is 40mN / m, the pH is 6.8, and the temperature is 45°C. The metal mass ratio in the etched metal film 12 is 70% copper, 10% zinc and 20% nickel, the etching time is 180s, and the width difference between lines after etching is within 5 μm, which meets the process requirements.

Embodiment 3

[0078] The mass percent of each component of the metal film etching solution 30 is: 8% FeCl 3 , 9% HCl, 1.25% NaClO 3 , 0.02% surfactant and the rest water, and the surface tension is 33mN / m, the pH is 6.1, and the temperature is 40°C. The mass ratio of the metal in the etched metal film 12 is 80% copper and 20% nickel, and the etching time is 120s. After the etching is completed, the width difference between the lines is within 4 μm, which meets the process requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com