Self-dust-removal type pyrolyzing and cracking tube cracking reactor

A pyrolysis reactor and cracking tube technology, which is applied in the field of pyrolysis and cracking of fossil fuels, can solve the problems of low value of pyrolysis oil and difficulty in effective utilization of pyrolysis oil, and achieve saving in construction costs, floor space, and structure Simple, high-yield results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification.

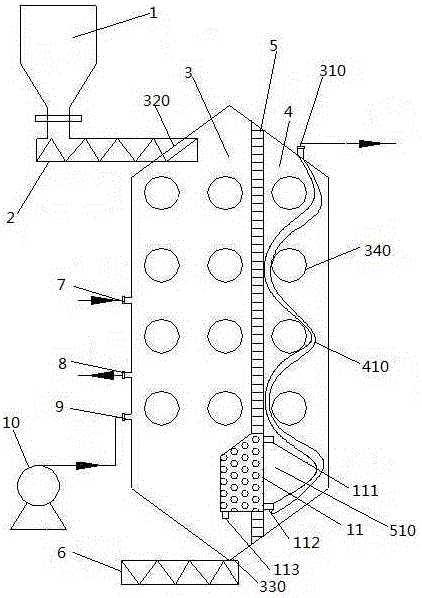

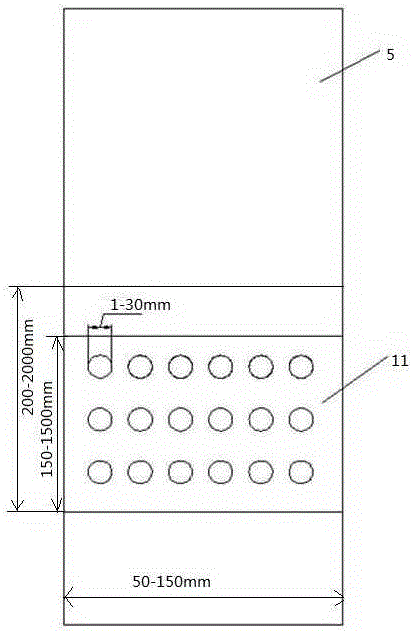

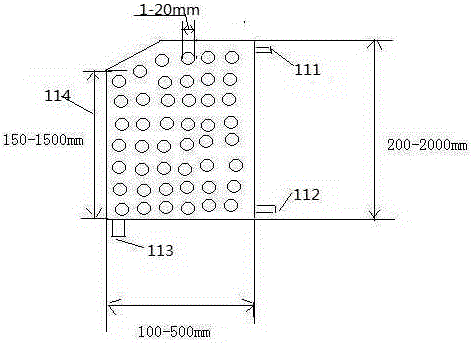

[0033] According to one aspect of the present invention, the present invention provides a kind of self-cleaning type pyrolysis and cracking tube cracking reactor, figure 1 It is the structural diagram of this self-cleaning type pyrolysis and pyrolysis tube pyrolysis reactor, such as figure 1 As shown, the reactor includes a feed inlet 320, a pyrolysis chamber 3, a cracking chamber 4, a pyroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com