Biodegradable material and preparation method thereof

A technology of biodegradable materials and inorganic fillers, applied in the field of biodegradable materials and their preparation, can solve the problems of high water vapor transmission rate of films and failure to meet packaging requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned biodegradable material comprises the following steps:

[0036] Step S110, using a high-speed mixer to stir each component evenly to obtain a mixture.

[0037] Preferably, the rotating speed of the high-speed stirring is 700-1300 rpm.

[0038] Step S120, extruding the mixture with a twin-screw extruder and then granulating to obtain the biodegradable material.

[0039] In one embodiment, the temperature of the twin-screw extruder is 120°C-180°C, the screw speed is 150-350rpm, and the aspect ratio is 30-40.

[0040] The preparation method of the biodegradable material is simple to operate.

[0041] A biodegradable film according to one embodiment is made of the above-mentioned biodegradable material.

[0042] In one embodiment, the thickness of the biodegradable film is 0.05-0.085 mm.

[0043] Dry the above biodegradable material at 85° C. for 3 hours, and use a blown film machine or cast film machine to prepare a biodegra...

Embodiment 1

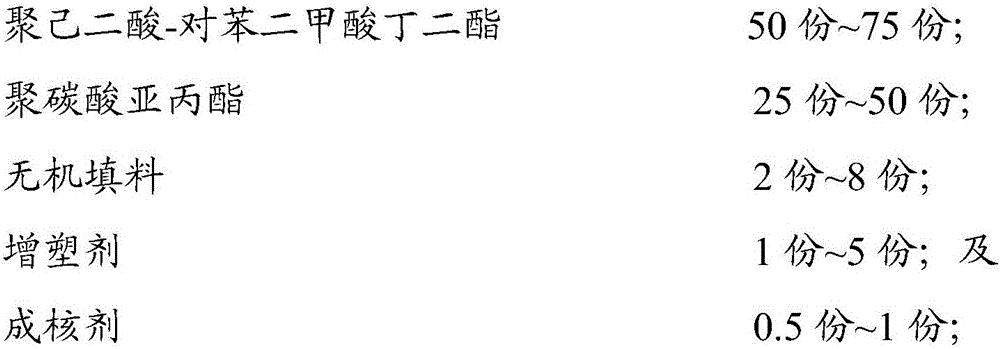

[0048] The composition of the biodegradable material of embodiment 1 is:

[0049]

[0050] Wherein, mica is mica modified by silane coupling agent.

[0051] The above-mentioned components were stirred for 0.5 hours with a high-speed mixer, and then extruded and granulated with a twin-screw extruder to obtain a biodegradable material. Twin-screw extruder temperature: 120°C, 135°C, 155°C, 165°C, 170°C, 175°C, 170°C, die head temperature 170°C, screw speed 250rpm, aspect ratio 36.

[0052] Dry the biodegradable material at 85°C for 3 hours, and use a film blowing machine to obtain a biodegradable film.

[0053] The thickness of the biodegradable film is 0.05mm.

Embodiment 2

[0055] The composition of the biodegradable material of embodiment 2 is:

[0056]

[0057] Wherein, the modified montmorillonite is montmorillonite modified by octadecyltrimethylammonium bromide.

[0058] The above components were stirred by a high-speed mixer for 0.5 hours, and then extruded and granulated by a twin-screw extruder to obtain a biodegradable material. Twin-screw extruder temperature: 120°C, 145°C, 155°C, 165°C, 175°C, 180°C, 175°C, die head temperature 170°C, screw speed 300rpm, aspect ratio 40.

[0059] Dry the biodegradable material at 85°C for 3 hours, and use a film blowing machine to obtain a biodegradable film.

[0060] The thickness of the biodegradable film is 0.085mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com