Preparation method of degradable waterborne polyurethane paint and product

A technology of water-based polyurethane and coatings, which is applied in the field of preparation of degradable water-based polyurethane coatings, can solve the problems of not widely used marine coatings, and achieve the effects of convenient operation, cheap raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

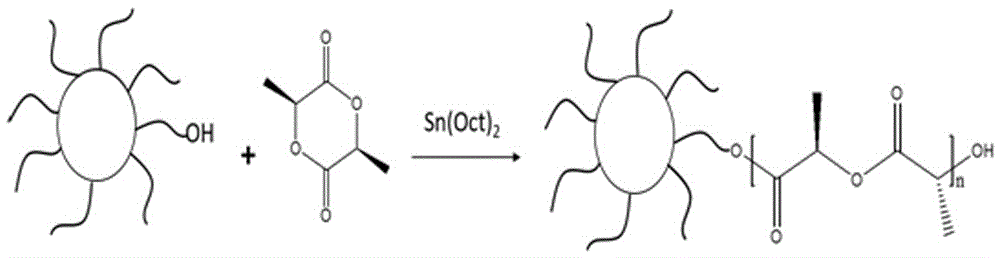

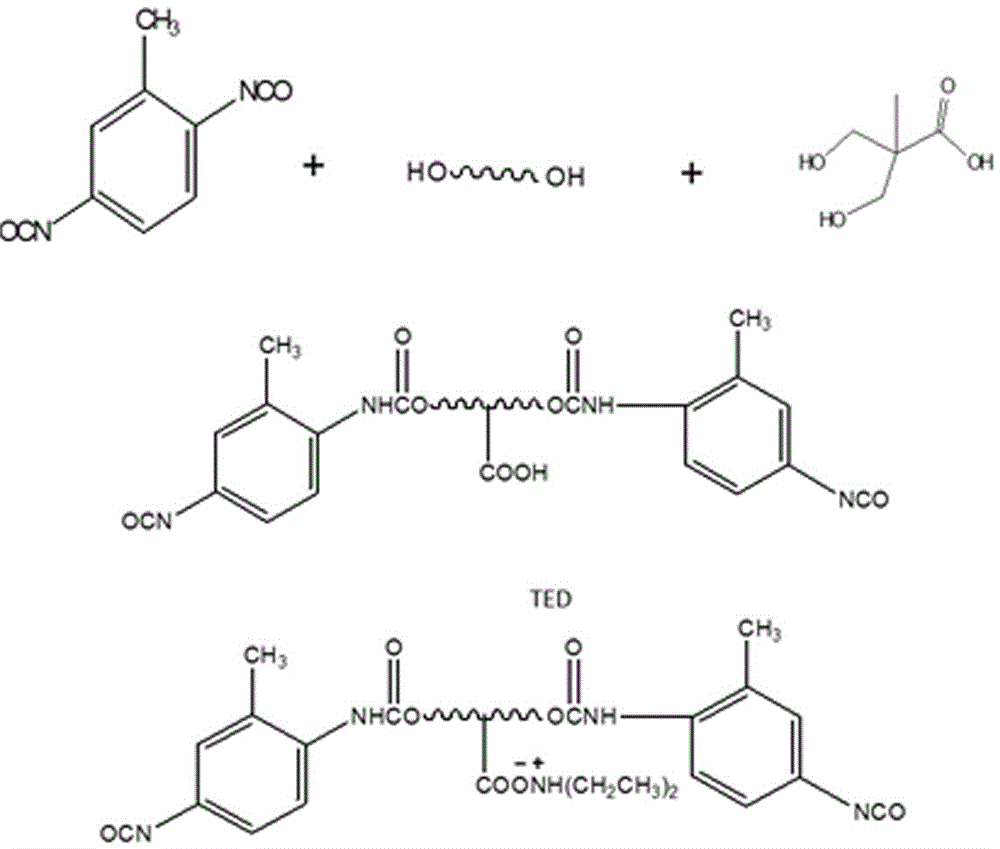

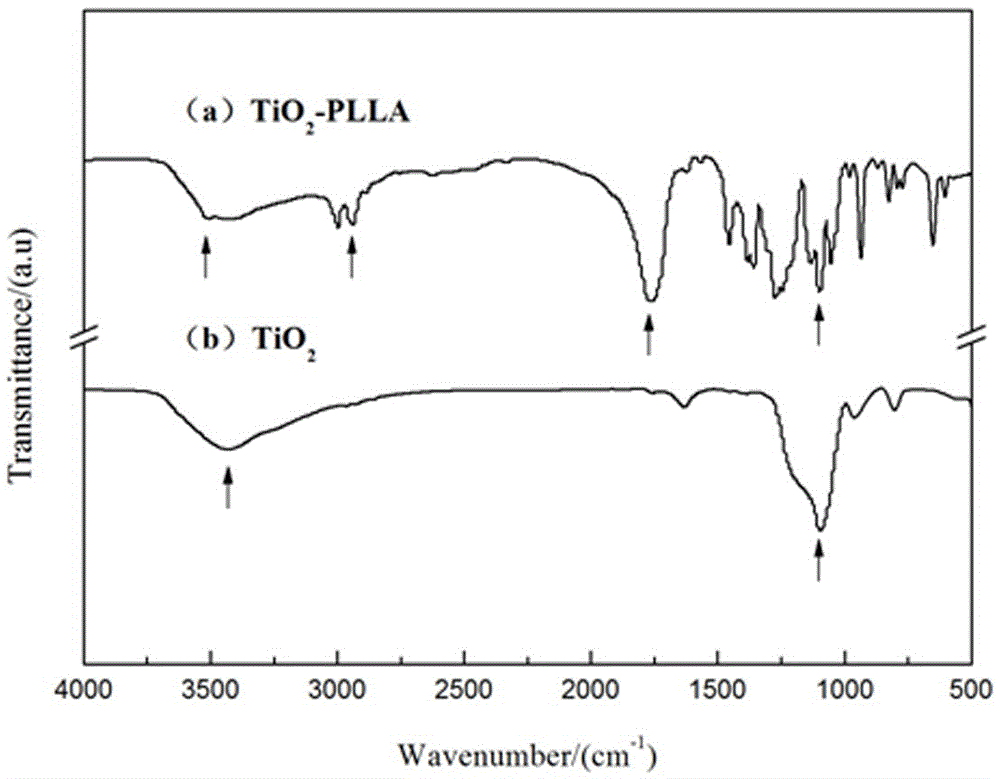

[0030] Vacuum-dry nano-titanium dioxide at 50°C for 24 h, fully mix 2.0 g of nano-titanium dioxide with 50 mL of anhydrous toluene, and disperse evenly by ultrasonic waves. Under the condition of nitrogen protection and constant temperature stirring at ℃ for 12 h, the hydroxyl group on the surface of nano-titanium dioxide initiates the ring-opening of lactide, and the titanium dioxide / polylactic acid composite material and anhydrous toluene mixture obtained by the reaction are added dropwise to 8 times the volume of n-hexane , and filtered under reduced pressure, the product was dried at 50°C for use. 2,2-Dihydroxymethylpropionic acid is dehydrated at 110°C, and polypropylene glycol is dehydrated at 110°C. Mix and stir 2.5 g of dry polypropylene glycol and 0.3 g of 2,2-dihydroxymethylpropionic acid, slowly add 0.25 g of toluene diisocyanate dropwise, and react at a constant temperature of 75°C for 8 h under nitrogen protection and strong stirring, then cool down After reachin...

Embodiment 2

[0032] Vacuum-dry nano-titanium dioxide at 50°C for 24 h, fully mix 2.0 g of nano-titanium dioxide with 50 mL of anhydrous toluene, and disperse evenly with ultrasonic waves. Under the condition of nitrogen protection and constant temperature stirring at ℃ for 12 h, the hydroxyl group on the surface of nano-titanium dioxide initiates the ring-opening of lactide, and the titanium dioxide / polylactic acid composite material and anhydrous toluene mixture obtained by the reaction are added dropwise to 8 times the volume of n-hexane , and filtered under reduced pressure, the product was dried at 50°C for use. 2,2-Dihydroxymethylpropionic acid is dehydrated at 110°C, and polypropylene glycol is dehydrated at 110°C. Mix and stir 2.5 g of dry polypropylene glycol and 0.3 g of 2,2-dihydroxymethylpropionic acid, slowly add 0.5 g of toluene diisocyanate dropwise, and react at a constant temperature of 75°C for 10 h under nitrogen protection and strong stirring, then cool down After reach...

example 3

[0034] Vacuum-dry nano-titanium dioxide at 50°C for 24 h, fully mix 2.0 g of nano-titanium dioxide with 50 mL of anhydrous toluene, and disperse evenly by ultrasonic waves. Under the condition of nitrogen protection and constant temperature stirring at ℃ for 12 h, the hydroxyl group on the surface of nano-titanium dioxide initiates the ring-opening of lactide, and the titanium dioxide / polylactic acid composite material and anhydrous toluene mixture obtained by the reaction are added dropwise to 8 times the volume of n-hexane , and filtered under reduced pressure, the product was dried at 50°C for use. 2,2-Dihydroxymethylpropionic acid is dehydrated at 110°C, and polypropylene glycol is dehydrated at 110°C. Mix and stir 5.0 g of dry polypropylene glycol and 0.6 g of 2,2-dihydroxymethylpropionic acid, slowly add 0.5 g of toluene diisocyanate dropwise, and react at a constant temperature of 75°C for 12 h under nitrogen protection and strong stirring, then cool down After reachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com