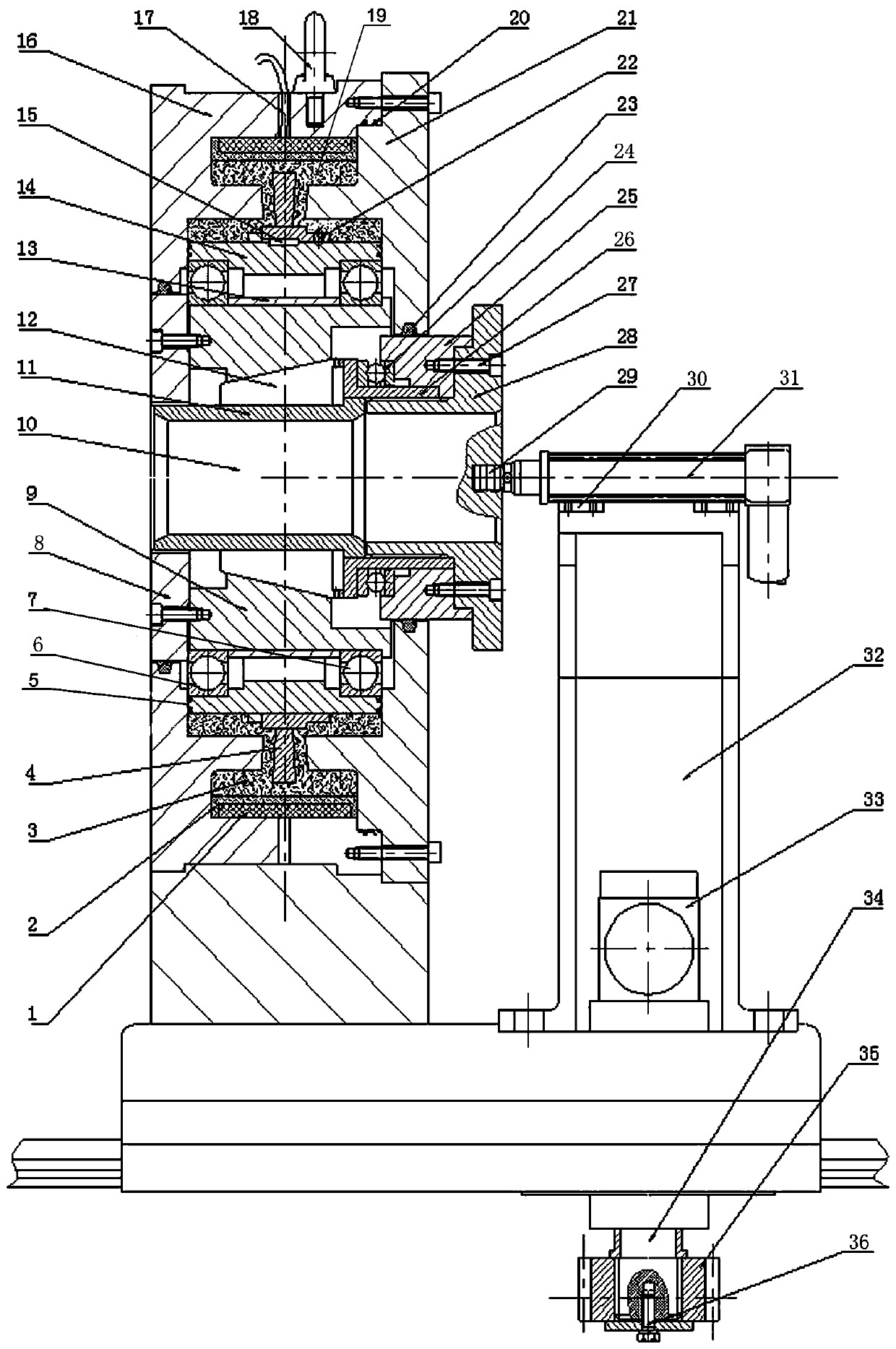

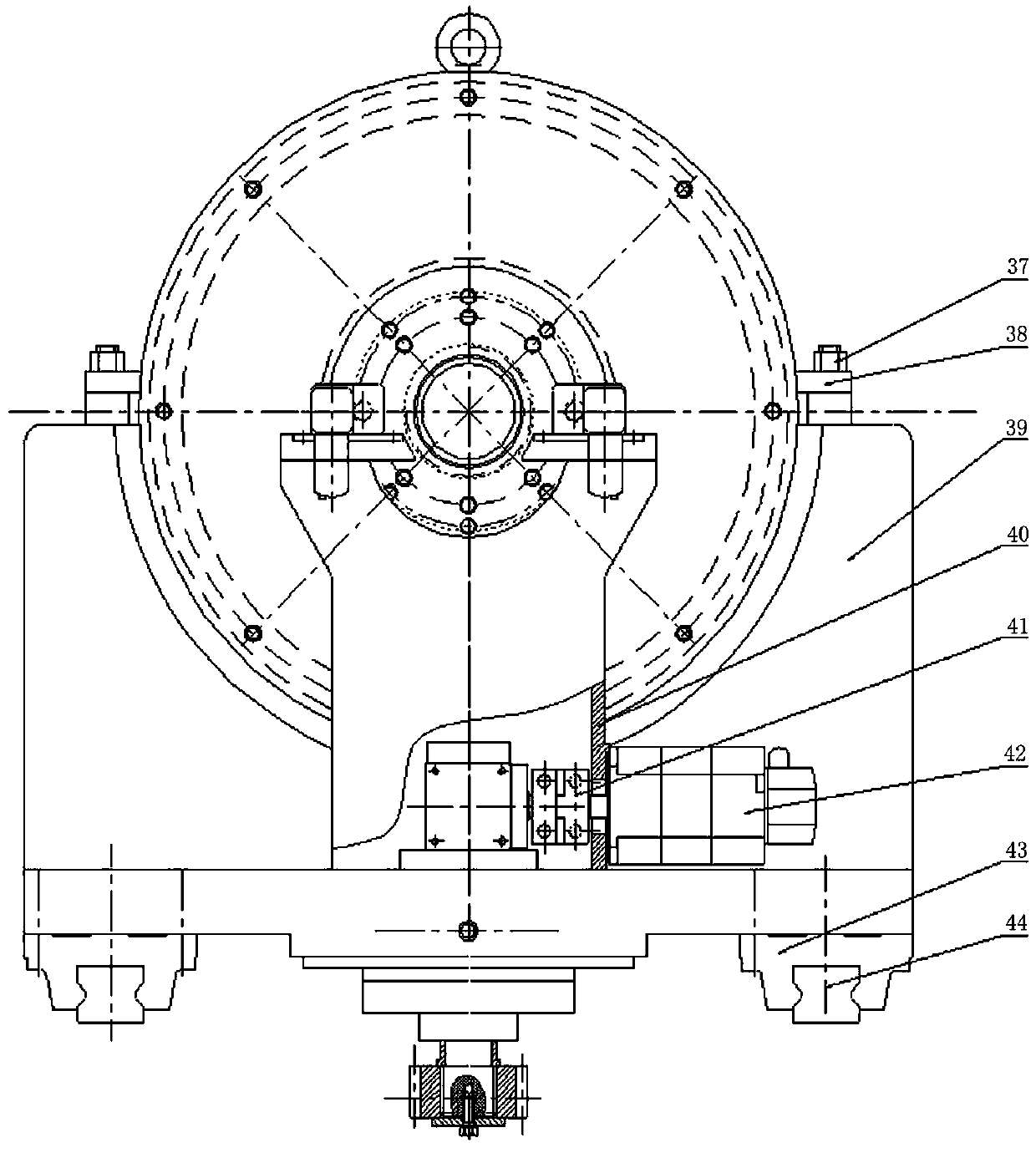

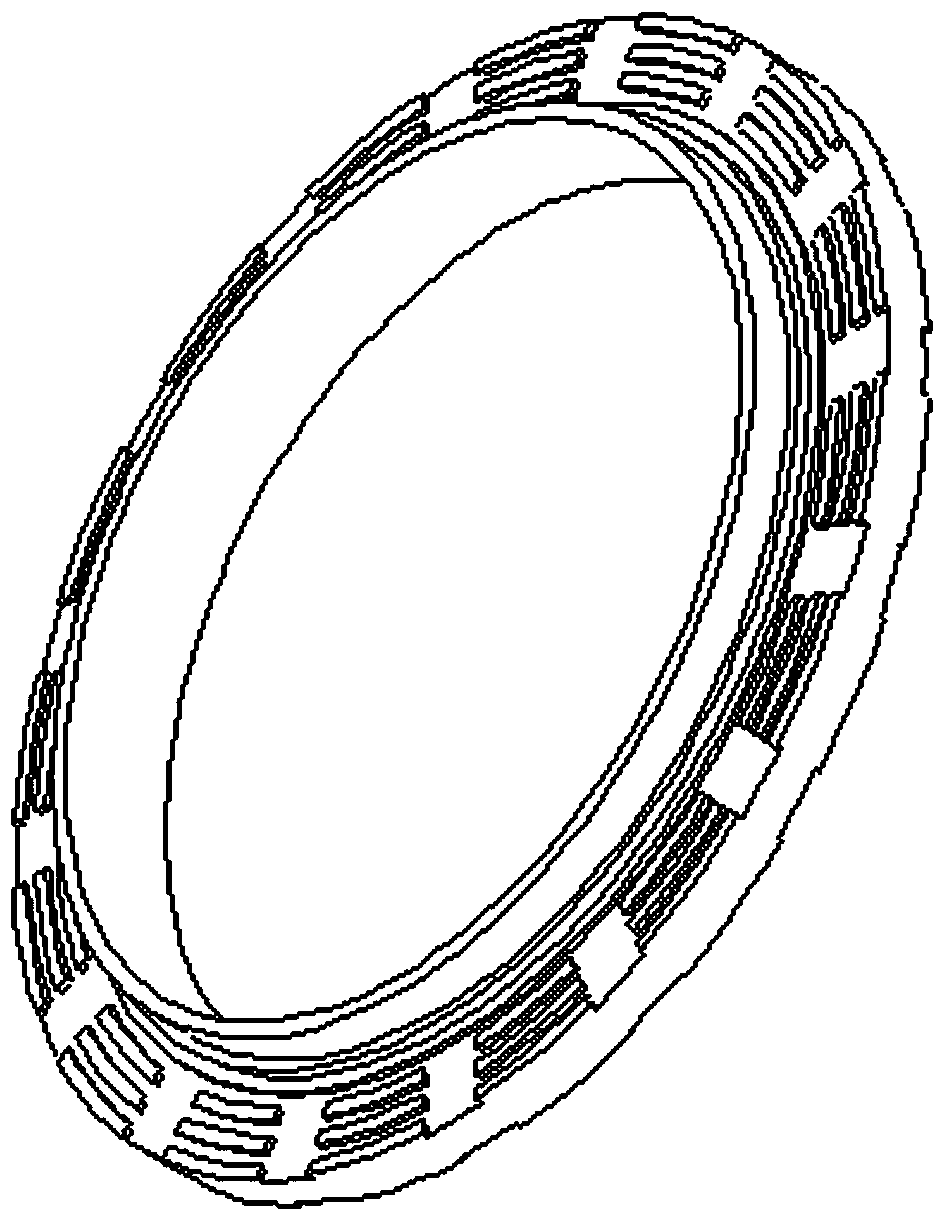

Composite intelligent deep hole processing shock absorber and optimal auxiliary support position self-moving control method

A composite, shock absorber technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as unsatisfactory vibration damping effect, and achieve the effect of compact structure, fast response, and good vibration damping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Experimental parameters: tool diameter is 18.91, drill pipe length is 1800, inner diameter is 11.5 and outer diameter is 17, Young's modulus E is 2.06*10 11 pa, processing alloy steel material, its density is 7.87*10 3 , processing depth 200, cutting fluid density 866kg / m 3 .

[0058] Solve the above equation to determine the position of the first auxiliary support , when the drilling depth ;Pick , to obtain the first five natural frequencies of the drill pipe, respectively 39.538, 103.718, 200.477, 329.390, 490.571; take , to obtain the first five natural frequencies of the drill pipe, respectively 39.261, 103.362, 200.016, 328.823, 482.325; Each value unit The natural frequency of the drill pipe at the node, while the cutting parameters such as the length and speed of the drill pipe remain unchanged during the machining process, compared with the natural frequency at each node, the optimal When , its natural frequency is 35.318, 98.630, 189.329, 318.469, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com