Backward extrusion forming method of stepped hollow shaft part and die

A forming die and extrusion forming technology, applied in the field of warm extrusion, can solve the problems of inaccurate positioning, difficult forming of inner holes, and high scrap rate, and achieve the effects of high dimensional accuracy, complex forming and high material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

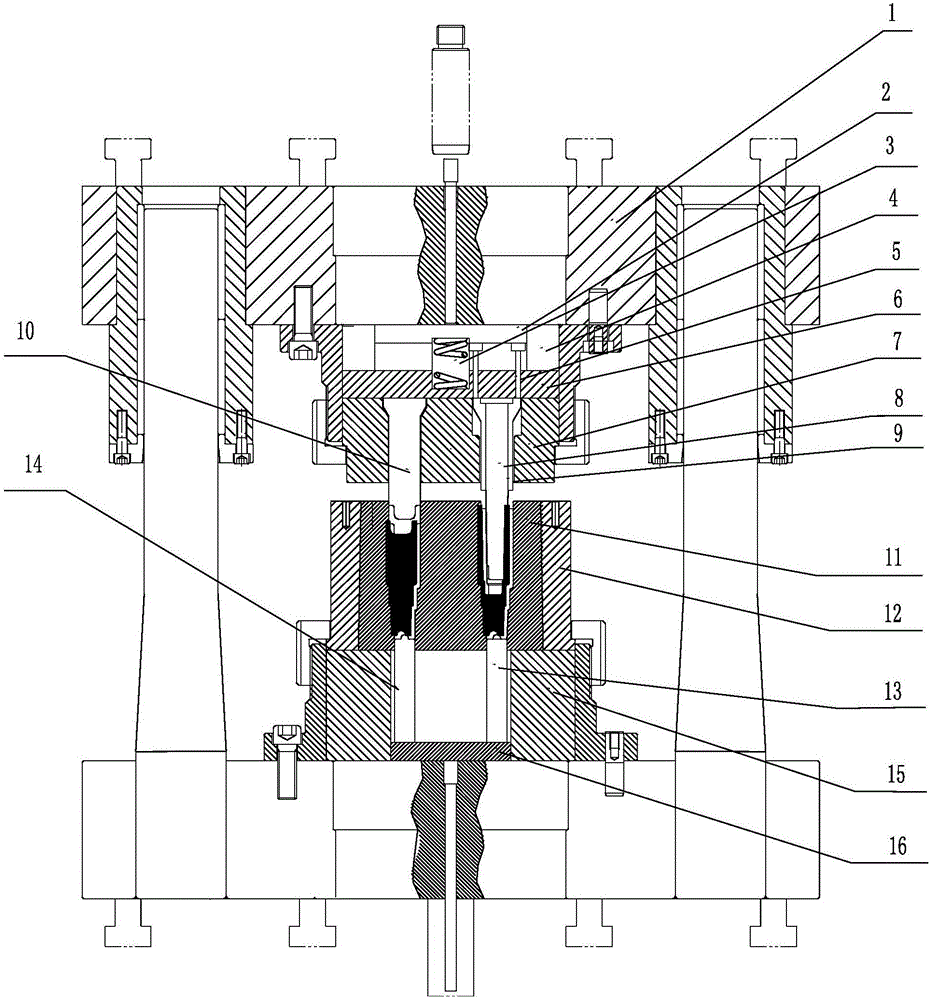

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0028] The invention discloses a reverse extrusion forming method of a stepped hollow shaft, which comprises the following steps:

[0029] 1) Cutting by cylindrical bar sawing machine;

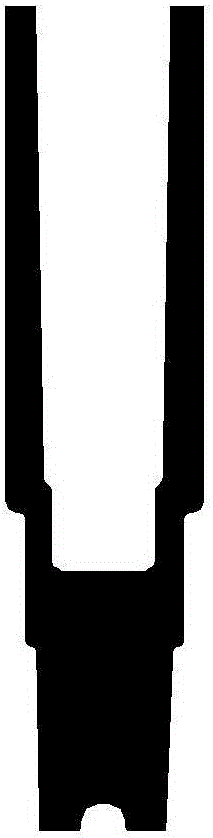

[0030] 2) Heat the material to 750°C through an intermediate frequency diathermy furnace, and then pre-extrude it, such as figure 2 shown;

[0031] 3) Put the pre-extruded forging quickly on the back-extrusion forming mold on one side, and perform closed back-extrusion forming, such as image 3 As shown; this step needs to grasp the speed beat, and minimize the influence of temperature drop on the process;

[0032] 4) Carry out rough turning on extruded parts to remove excess waste;

[0033] 5) Shot blasting is carried out on the forgings to obtain qualified fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com