Automobile intake and exhaust flange and forging technology thereof

An air intake and exhaust and flange technology, which is applied in the field of mechanical forging, can solve the problems of insignificant improvement of material utilization rate, high production cost of cold plate, unstable edge density of products, etc. The effect of improving efficiency and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

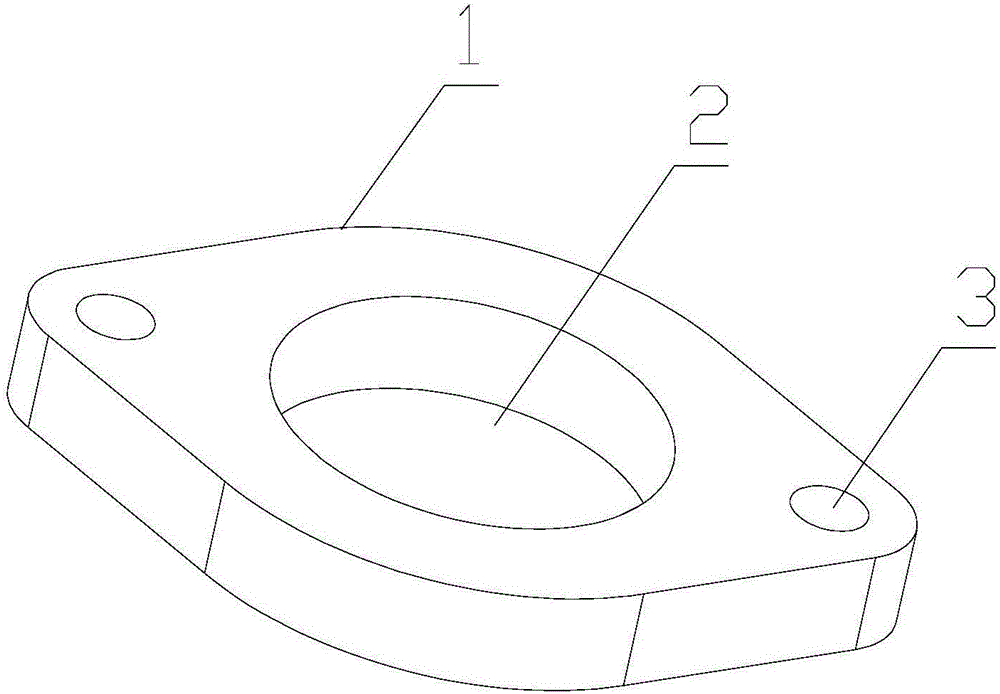

[0033] Such as figure 1 As shown, it is the automobile intake and exhaust flange of the present invention. The flange includes a main body 1 with a middle hole 2 and a mounting hole 3 at both ends of the middle hole 2 . The length of the mounting hole 3 and the aperture ratio of the mounting hole 3 are 1.3-1.5:1. In this embodiment, the thickness of the flange is 15 mm, the diameter of the mounting hole 3 is 11.5 mm, and the ratio of the length of the mounting hole 3 to the aperture It is 1.3, that is, the flange is a thick flange.

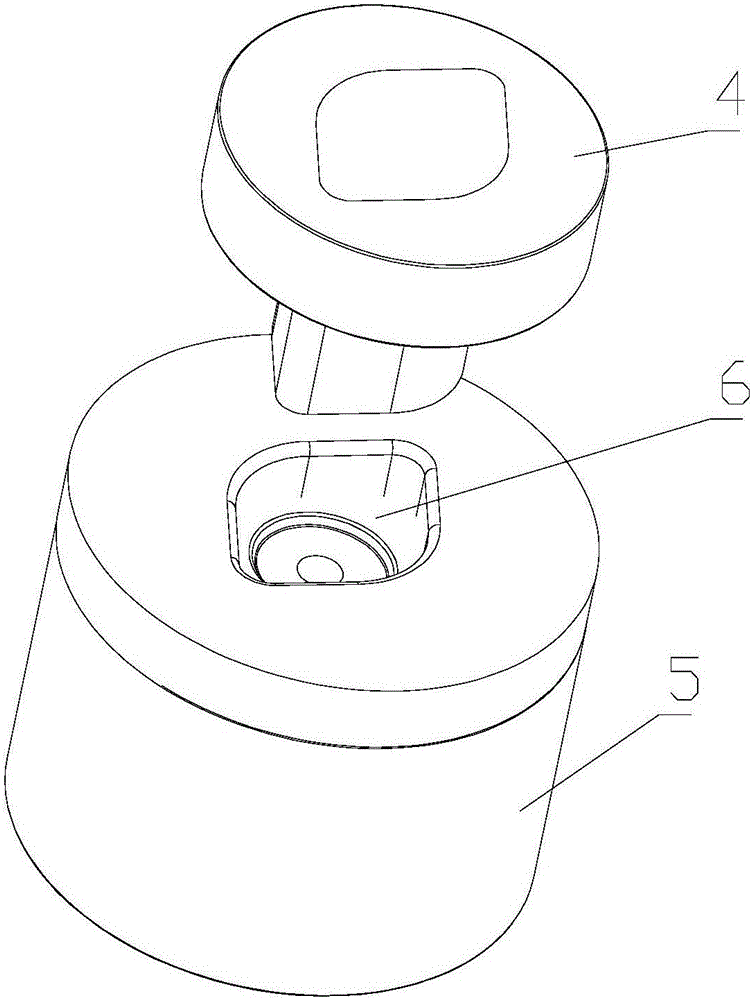

[0034] Such as figure 2 Shown, be the closed mold of the present invention, described closed mold comprises upper mold 4 and lower mold 5, and upper mold 4 and lower mold 5 surround and form molding cavity 6, and the shape of molding cavity 6 and described flange The shape fits.

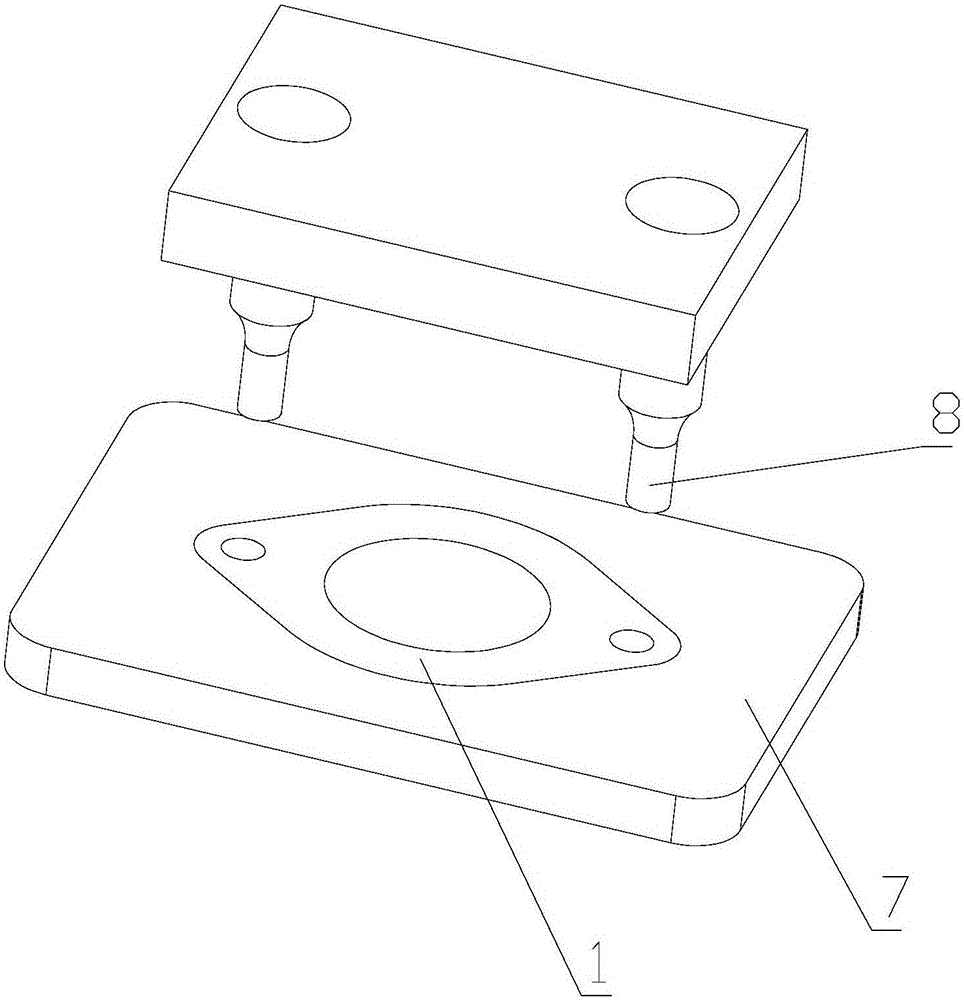

[0035] Such as image 3 Shown is the hydraulic press of the present invention, the hydraulic press includes a workbench 7 and a punch 8, the workbench 7 is provided...

Embodiment 2

[0049] In this embodiment, the structure of the flange, closed die and hydraulic press is the same as in Embodiment 1, the difference lies in the forging process of the flange, as follows:

[0050] A forging process for an automobile intake and exhaust flange, comprising the following steps:

[0051] (a) Cutting: Use a cutting machine or a band sawing machine to saw the rod-shaped raw material into a spare blank of the size required by the process;

[0052] (b) Heating: heat the billet through an intermediate frequency furnace for 4S, and the heating temperature is 1100°C;

[0053] (c) Pre-forging: the heated billet is flattened with a mold, the working pressure of the machine tool for flattening the billet is 70T, and the temperature of the flattened billet is 1200°C;

[0054] (d) Final forging: put the flattened blank into the closed die cavity for processing, and the final forging working pressure of the machine tool is 850T to obtain the blank;

[0055](e) punching the c...

Embodiment 3

[0060] In this embodiment, the structure of the flange, closed die and hydraulic press is the same as in Embodiment 1, the difference lies in the forging process of the flange, as follows:

[0061] A forging process for an automobile intake and exhaust flange, comprising the following steps:

[0062] (a) Cutting: Use a cutting machine or a band sawing machine to saw the rod-shaped raw material into a spare blank of the size required by the process;

[0063] (b) Heating: heat the billet through an intermediate frequency furnace for 7S, and the heating temperature is 1200°C;

[0064] (c) Pre-forging: flatten the heated billet with a mold, the working pressure of the machine tool to flatten the billet is 50T, and the temperature of the flattened billet out of the furnace is 1200°C;

[0065] (d) Final forging: put the flattened blank into the closed die cavity for processing, and the final forging working pressure of the machine tool is 750T to obtain the blank;

[0066] (e) pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com