Hydraulic separating all-in-one machine for garbage

A technology of hydraulic separation and all-in-one machine, applied in the directions of magnetic separation, solid separation, wet separation, etc., can solve the problems of inability to distinguish the types of wastes heavier than water, complex structure, etc., achieve compact structure, long residence time, separation thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The patent of the present invention will be further described below in conjunction with the accompanying drawings.

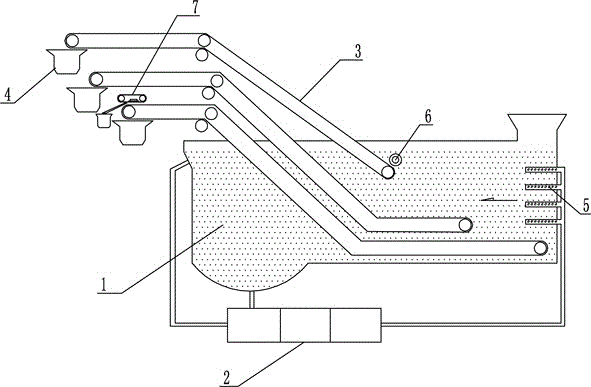

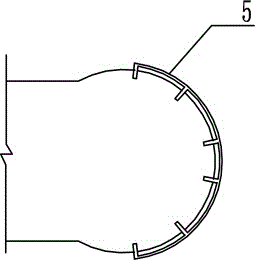

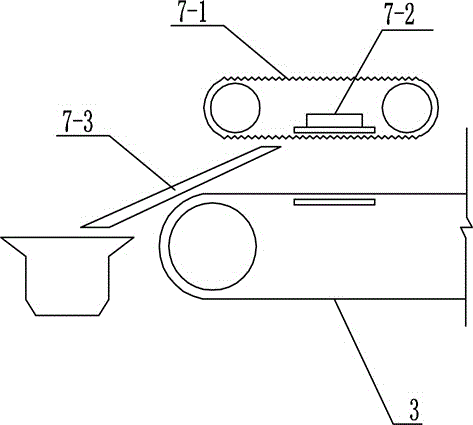

[0021] The garbage hydraulic sorting integrated machine is characterized in that it includes a working pool 1, a sewage treatment system 2, a conveyor belt 3 and a discharge port 4, wherein: the top of the working pool 1 is provided with a feed port, and several A group of water spray pipes 5, each group of water spray pipes 5 is arc-shaped around the side of the feed inlet; an overflow port is provided at the end of the water flow direction of the working pool 1, and the overflow port is connected to the sewage treatment system 2, and the purification outlet of the sewage treatment system 2 passes through the water pump and The water spray pipe 5 is connected; the bottom of the working pool 1 is provided with a downward depression along the water flow direction, and the depression is connected with the sewage treatment system 2; three sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com