A preparation method of a hydrodeoxygenation isomerization catalyst, a hydrodeoxygenation isomerization catalyst and its application

A hydrodeoxygenation and catalyst technology, which is applied in molecular sieve catalysts, fatty acid isomerization, chemical instruments and methods, etc., can solve the problems of poor adjustment of catalyst acidity and high requirements for catalyst selectivity, etc., achieve rich channels and increase catalytic efficiency , high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of a hydrodeoxygenation isomerization catalyst is characterized in that comprising the following steps:

[0041] Step a: Attachment of active components: attaching the active components to carbon nanotubes;

[0042] Step b: synthesis of hydrodeoxygenation isomerization catalyst: mixing and stirring the modified carbon nanotubes with active components attached to deionized water, silica sol, phosphoric acid and pseudo-boehmite, adding the mixture to the template agent and stirring, Recrystallization, washing, calcination and reduction are carried out to obtain the desired hydrodeoxygenation isomerization catalyst.

[0043] In the step b, a precipitant is added to the crystallized mixture for precipitation, and then washing and roasting are performed to precipitate free active components, so as to ensure the effect of the catalyst.

[0044] The process of the step a is as follows: 1) firstly, the carbon nanotubes are hydroxylated to obtain hydroxylat...

Embodiment 1

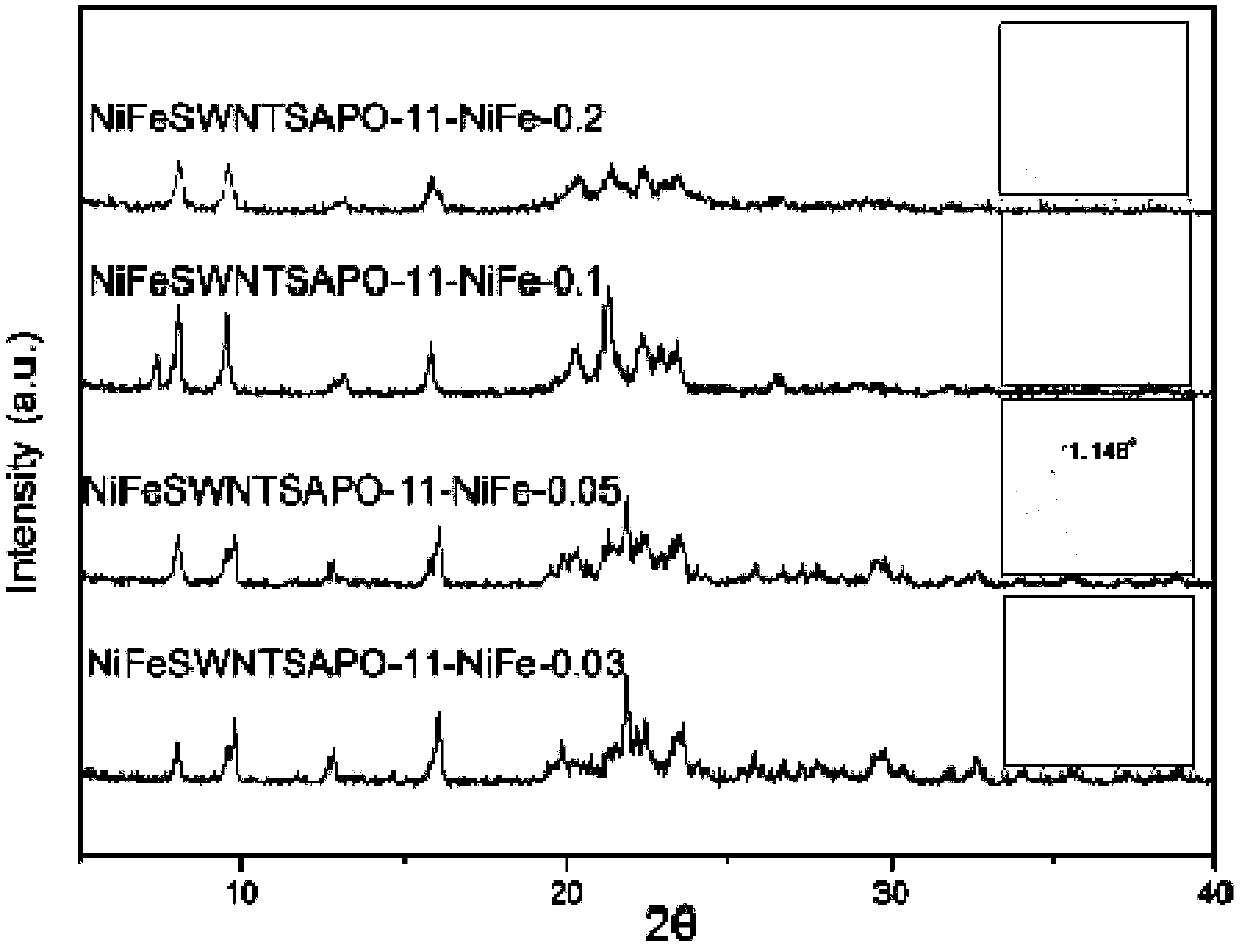

[0067] Example 1: Preparation of NiFeMWNTSAPO-11 catalyst

[0068] (1) NiFeMWNT-NH 2 Preparation steps: first, 10g of carbon nanotubes were added to 30g of 10% potassium hydroxide ethanol solution, refluxed and stirred at 80 ° C for 3-5 hours, and then the obtained mixed solution was vacuum filtered and filtered. The cake was repeatedly washed with distilled water until the pH value of the solution was washed to neutrality, and the filter cake finally obtained was dried in an oven at 110°C for 4-8 hours to obtain MWNT-OH. Then, the obtained 5g MWNT-OH powder was added to 15g DMF solution, refluxed and stirred at 110°C for half an hour, and then 1.5g KH-570 was added to continue stirring under this condition for 10 hours, and then the obtained mixed solution was filtered under reduced pressure. Then the obtained filter cake was washed repeatedly with DMF until the pH value of the solution was washed to neutrality, and the finally obtained filter cake was dried in an oven at 11...

Embodiment 2

[0073] Example 2: Preparation of NiFeMWNTSAPO-11 catalyst

[0074] (1) NiFeMWNT-NH 2 Preparation steps: firstly, 10g of carbon nanotubes were added to 30g of 10% potassium hydroxide ethanol solution, refluxed and stirred at 80 ° C for 3-5 hours, then the obtained mixed solution was vacuum filtered, and then the obtained filtered The cake was repeatedly washed with distilled water until the pH value of the solution was washed to neutrality, and the filter cake finally obtained was dried in an oven at 110° C. for 4-8 hours to obtain MWNT-OH. Then, the obtained 5g MWNT-OH powder was added to 15g DMF solution, refluxed for half an hour at 110°C, and then 1.5g KH-570 was added to continue stirring under this condition for 10 hours, and then the obtained mixed solution was filtered under reduced pressure. Then the obtained filter cake was washed repeatedly with DMF until the pH value of the solution was washed to neutrality, and the finally obtained filter cake was dried in an oven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com