Industrial sulfur-containing waste gas modified carbon-based adsorbent and preparation method and application thereof

An industrial waste gas and adsorbent technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of inability to realize resource recovery and utilization, poor desorption effect, etc., to reduce total mercury content and reduce mercury removal. cost, the effect of reducing the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

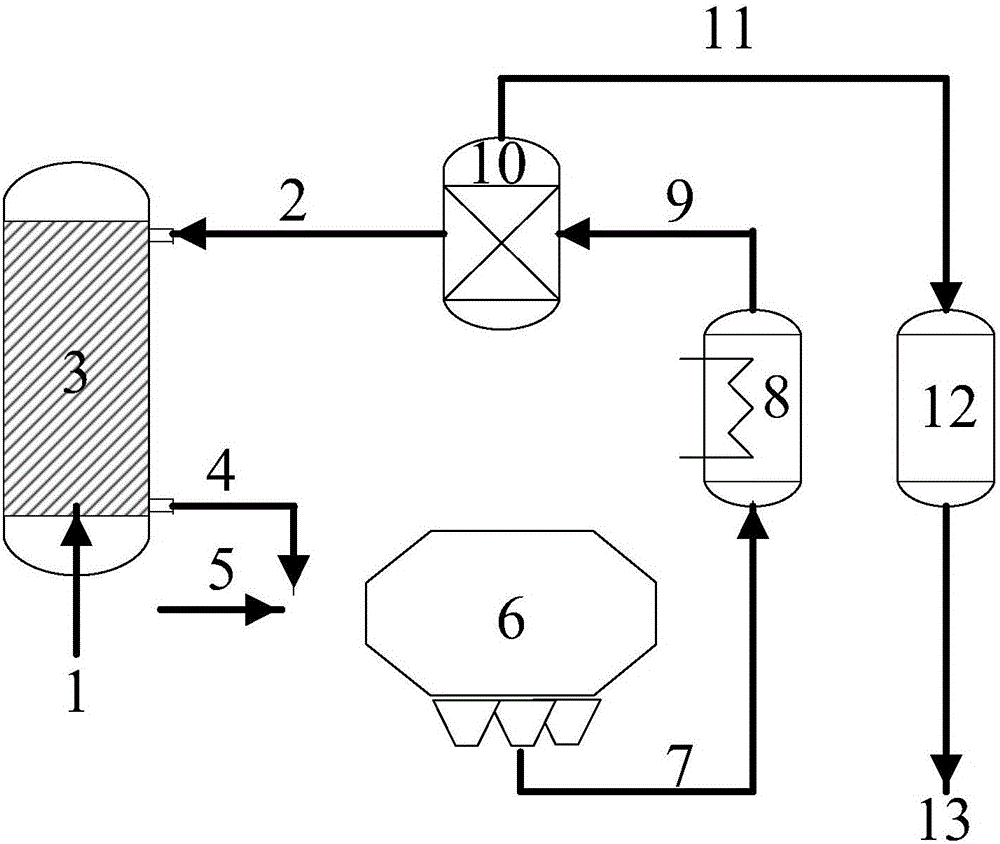

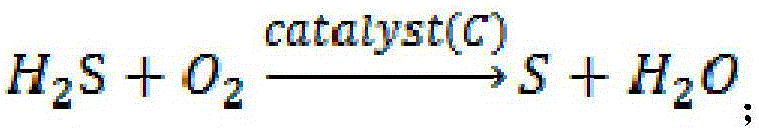

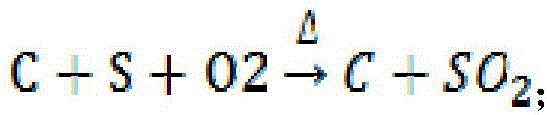

[0039] Such as figure 1 As shown, the present invention relates to a kind of industrial sulfur-containing waste gas modified carbon-based adsorbent flue gas demercuration and regeneration method, including carbon-based adsorbent sulfur loading activation reactor 3, dust removal capture separation device 6, mercury desorption reactor 8. Mercury separation reactor 10 and mercury condensation recovery device 12, sulfur-containing industrial waste gas 1 enters carbon-based adsorbent sulfur-loaded activation reactor 3 from bottom to top; activated sulfur-loaded adsorbent 4 is directly sprayed into mercury-containing flue gas In 5, the outlet of the mixture is connected to the dust removal capture separation device 6; the mercury-rich adsorbent 7 at the outlet of the dust removal capture separation device 6 is connected to the bottom of the mercury desorption reactor 8; the outlet of the desorption reactor 8 is connected to the mercury separation reactor 10 is connected through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com