Conductive parallel fiber membrane capable of promoting rapid repair of peripheral nervous tissues and preparation method of conductive parallel fiber membrane

A peripheral nerve and parallel fiber technology, applied in the field of nerve repair biomaterial preparation, can solve problems such as inability to use in large quantities in clinical use, inability to apply to nerve defects, and difficulty in extracting stem cells, achieving good biocompatibility and functionality, and a simple preparation device , the effect of easy parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

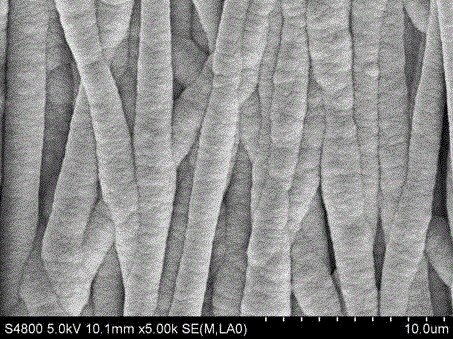

Embodiment 1

[0028] Dissolve 0.18 g of polylactic acid-polycaprolactone in 3 mL of dichloromethane, the viscosity of polylactic acid-polycaprolactone is 2.85 dL / g, stir magnetically at 200 rpm for 4 hours, mix well to obtain a concentration of 60 mg / mL polylactic acid-polycaprolactone electrospinning solution, seal it during stirring and dissolving to prevent solvent volatilization. The obtained electrospinning solution was added to the syringe of the electrospinning device, and the ambient temperature was 18 °C, the spinneret voltage was 10 kV, the spinning distance was 10 cm, the spinning solution injection speed was 1.0 mL / h, and the drum Electrospinning is carried out under the condition of rotating speed of 900 rpm, and the drum with a diameter of 12 cm is wrapped with aluminum foil to receive the fiber filaments. After 2 hours, the electrospun polylactic acid-polycaprolactone with oriented structure can be received on the aluminum foil. silk fiber membrane. Peel off the parallel po...

Embodiment 2

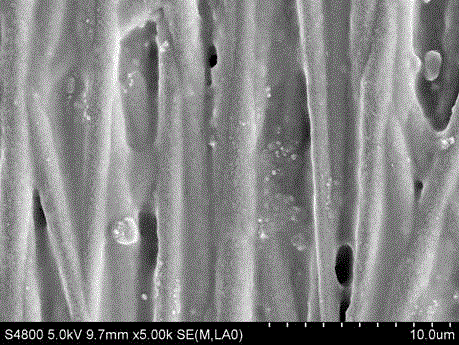

[0033] Dissolve 0.24 g of polylactic acid-polycaprolactone in 3 mL of dichloromethane, the viscosity of polylactic acid-polycaprolactone is 2.85 dL / g, stir magnetically at 300 rpm for 3 hours, mix well, and obtain a concentration of 80 mg / mL polylactic acid-polycaprolactone electrospinning solution should be sealed during stirring and dissolving to prevent solvent volatilization. The electrospinning solution was added to the syringe of the electrospinning device, and the ambient temperature was 25 °C, the spinneret voltage was 11 kV, the spinning distance was 10 cm, the injection speed of the spinning solution was 1.8 mL / h, and the rotation speed of the drum was Under the condition of 600 rpm, electrospinning is carried out, and the drum with a diameter of 12 cm is used to wrap the aluminum foil to receive the fiber filaments. After 1.5 hours, the electrospun polylactic acid-polycaprolactone with a parallel orientation structure is received on the aluminum foil. silk fiber mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com