Colored steel foamed cement laminboard

A technology of foamed cement and sandwich panels, which is applied to building materials, building components, buildings, etc., and can solve problems such as accumulation of aging peeling surfaces and poor bonding of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings

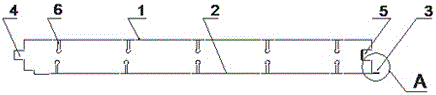

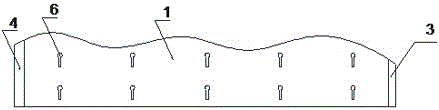

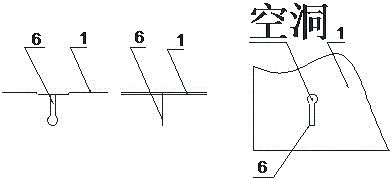

[0015] 1. Attached figure 1 It is a schematic diagram of the end face structure of the metal rectangular cavity of the present invention. The rectangular metal cavity is formed by rolling according to the width of the plate, and is connected by a biting method (3). The long sides are the panel (1) and the bottom plate (2). On the face plate and the bottom plate, there are rolled and stamped long metal plate ribs (6) to extend into the cavity. The panel and bottom plate can be laminated for anti-seepage and cleaning

[0016] 2. Fill the metal rectangular cavity with foamed cement or lightweight concrete. When filling foamed cement, the metal rectangular cavities are stacked horizontally (slightly inclined); when filling light-weight concrete, they are arranged vertically (instead of the current mold for producing lightweight foamed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com