A kind of facing adhesive film paper with health care function and preparation method thereof

A film-coated paper and veneer technology, applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of complex process and improvement of dispersion uniformity effect, achieve uniform particle size, high efficiency and economic benefits, improve grinding effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

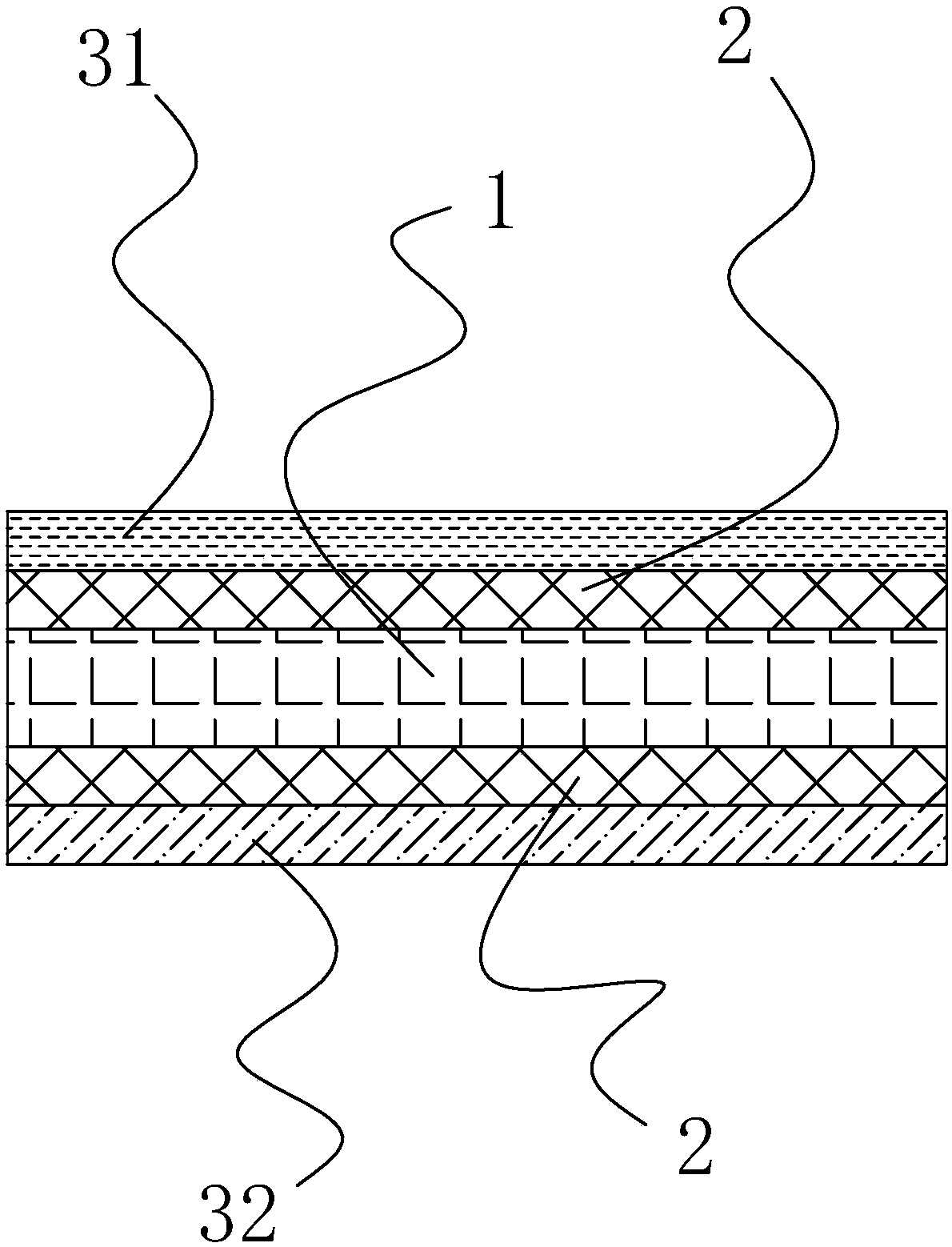

[0053] A kind of veneer adhesive film paper with health care function, it comprises melamine formaldehyde resin top coat 31, urea-formaldehyde resin middle layer 2, base material 1, urea-formaldehyde resin middle layer 2 and melamine formaldehyde resin back coat that have from top to bottom 32.

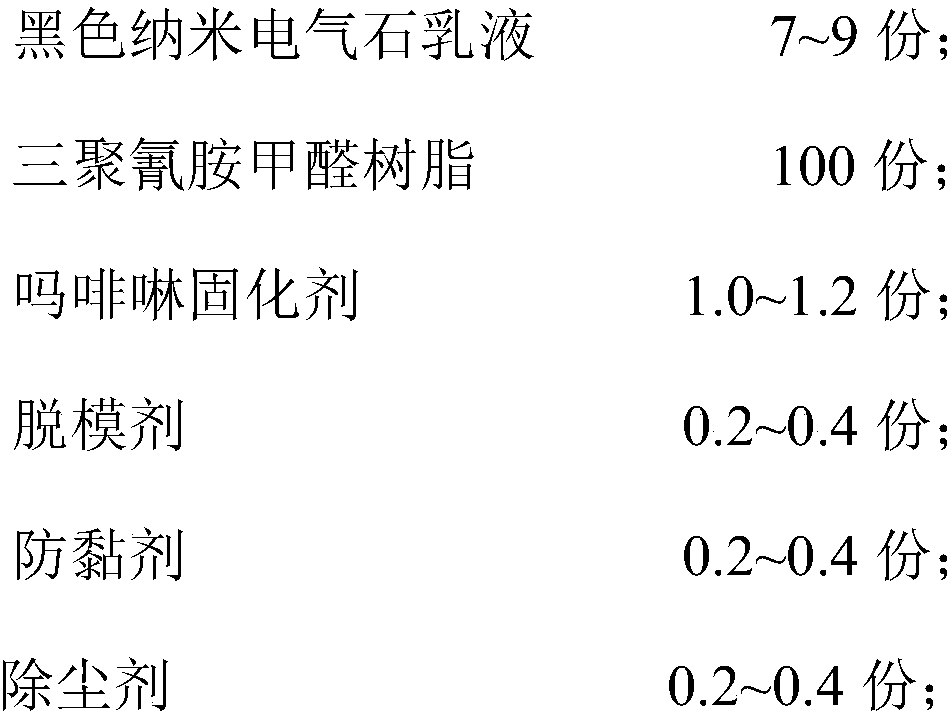

[0054] The effective raw material composition of described melamine formaldehyde resin top coat is white nano tourmaline emulsion, the effective raw material composition of described melamine formaldehyde resin back coat is black nano tourmaline emulsion, described white nano tourmaline emulsion and black tourmaline emulsion The carrier resins are all polyvinyl alcohol.

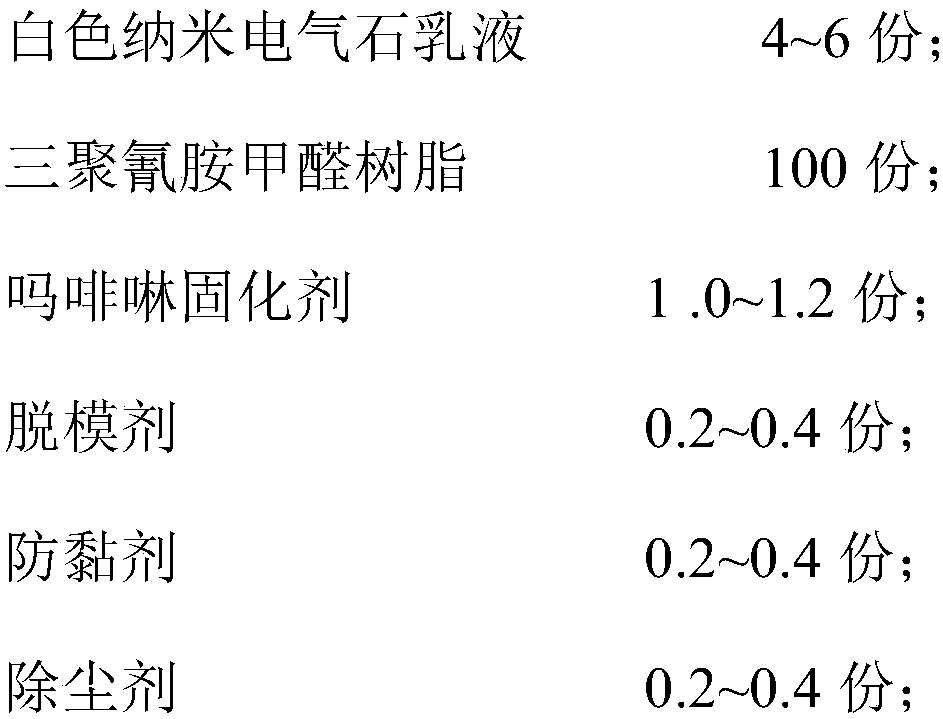

[0055] As a further embodiment, the raw material components of the melamine formaldehyde resin top coat are as follows in parts by weight:

[0056] White Nano Tourmaline Emulsion 4 parts

[0057] 100 parts of melamine formaldehyde resin

[0058] Morpholine curing agent 1.2 parts

[0059] Release agent 0.2 parts ...

Embodiment 2

[0085] Except that the raw material composition of the melamine-formaldehyde resin top coat and the raw material composition ratio of the melamine-formaldehyde resin back coat are different from Implementation 1, the remaining contents are the same, specifically:

[0086] The raw material component of described melamine formaldehyde resin top coat is as follows by weight:

[0087] White Nano Tourmaline Emulsion 6 parts

[0088] 100 parts of melamine formaldehyde resin

[0089] Morpholine curing agent 1 part

[0090] Release agent 0.4 parts

[0091] Anti-sticking agent 0.4 parts

[0092] Dust remover 0.4 parts.

[0093] The raw material component of described melamine formaldehyde resin back coating is as follows in parts by weight:

[0094] Black Nano Tourmaline Emulsion 9 parts

[0095] 100 parts of melamine formaldehyde resin

[0096] Morpholine curing agent 1 part

[0097] Release agent 0.4 parts

[0098] Anti-sticking agent 0.4 parts

[0099] Dust remover 0.4 part....

Embodiment 3

[0101] Except that the raw material composition of the melamine-formaldehyde resin top coat and the raw material composition ratio of the melamine-formaldehyde resin back coat are different from Implementation 1, the remaining contents are the same, specifically:

[0102] The raw material component of described melamine formaldehyde resin top coat is as follows by weight:

[0103] White nano tourmaline emulsion 5 parts

[0104] 100 parts of melamine formaldehyde resin

[0105] Morpholine curing agent 1.1 parts

[0106] Release agent 0.3 parts

[0107] Anti-sticking agent 0.3 parts

[0108] Dust remover 0.3 parts.

[0109] The raw material component of described melamine formaldehyde resin back coating is as follows in parts by weight:

[0110] Black Nano Tourmaline Emulsion 8 parts

[0111] 100 parts of melamine formaldehyde resin

[0112] Morpholine curing agent 1 part

[0113] Release agent 0.3 part

[0114] Anti-sticking agent 0.3 parts

[0115] Dust remover 0.3 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com