Rotary magnetron target and horizontal magnetron sputtering coating equipment

A magnetron target and rotary technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of prolonging the coating cycle of the vacuum coating system, difficulty in improving the coating efficiency, and affecting the coating effect of new workpieces and other problems, to achieve the effect of shortening the workpiece coating cycle, shortening the production cycle, and shortening the cycle cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

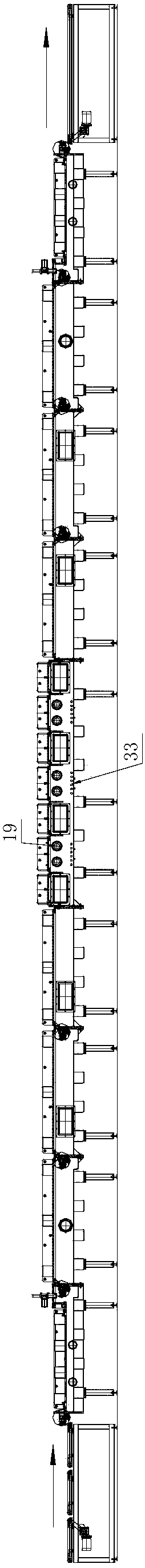

Image

Examples

Embodiment 1

[0035] A kind of rotary magnetron target of present embodiment, such as figure 1 As shown, it includes a target 1, a magnetic core 2 and a magnet 3. The magnetic core is arranged in the middle of the target, and at least one magnet is arranged on the outer periphery of the magnetic core. The end of the magnet facing the target is tapered.

[0036] The target is a hollow cylindrical structure, and the magnetic core and magnet are located in the space in the middle of the target.

[0037] The magnetic core is a hollow cylindrical structure, the outer periphery of the magnetic core is provided with a fixing frame 4, and the magnet is installed on the fixing frame. The fixing frame can adopt a fan-shaped structure or a support frame similar to a fan-shaped structure. Its main function is to install the magnet. The fixing frame part located at the outer circumference of the tapered end of the magnet can be an open structure (that is, the tapered end of the magnet is directly close ...

Embodiment 2

[0043] This embodiment is a rotary magnetron target. Compared with Embodiment 1, the difference is that: in the same axial section of the target (that is, in the vertical direction of the workpiece conveying direction), when the magnet is a split structure , the magnet is composed of multiple sub-blocks distributed side by side, each sub-block is a cylindrical structure, and the tapered end of each sub-block is conical.

[0044] The target and the magnetic core are concentrically arranged, and the magnet is located in the annular space formed between the target and the magnetic core; in the same radial section of the target (that is, in the direction parallel to the workpiece conveying direction), there are three sets of magnets on the outer periphery of the magnetic core , three groups of magnets are installed side by side on the fixed frame, that is, in this structure, there are three groups of magnets composed of blocks in the entire rotating target. However, in practical a...

Embodiment 3

[0046] This embodiment is a rotary magnetron target. Compared with Embodiment 1, the difference is that: in the same axial section of the target (that is, in the vertical direction of the workpiece conveying direction), when the magnet is a split structure , the magnet is composed of a plurality of sub-blocks distributed side by side, each sub-block is a cuboid structure, and the tapered end of each sub-block is in the shape of a quadrangular pyramid.

[0047] The target and the magnetic core are concentrically arranged, and the magnet is located in the annular space formed between the target and the magnetic core; in the same radial section of the target (that is, in the direction parallel to the workpiece conveying direction), there are three sets of magnets on the outer periphery of the magnetic core , three groups of magnets are installed side by side on the fixed frame, that is, in this structure, there are three groups of magnets composed of blocks in the entire rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com