Preparation and application of hollow spherical-segment-shaped mesoporous silica/chloroperoxidase nanoreactor

A technology of mesoporous silica and chloroperoxidase, applied in chemical instruments and methods, immobilized on or in inorganic carriers, water pollutants, etc., can solve the problem of high porosity, mesoporous materials and enzyme molecules Problems such as size mismatch, achieve good degradation ability, improved acid and alkali tolerance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

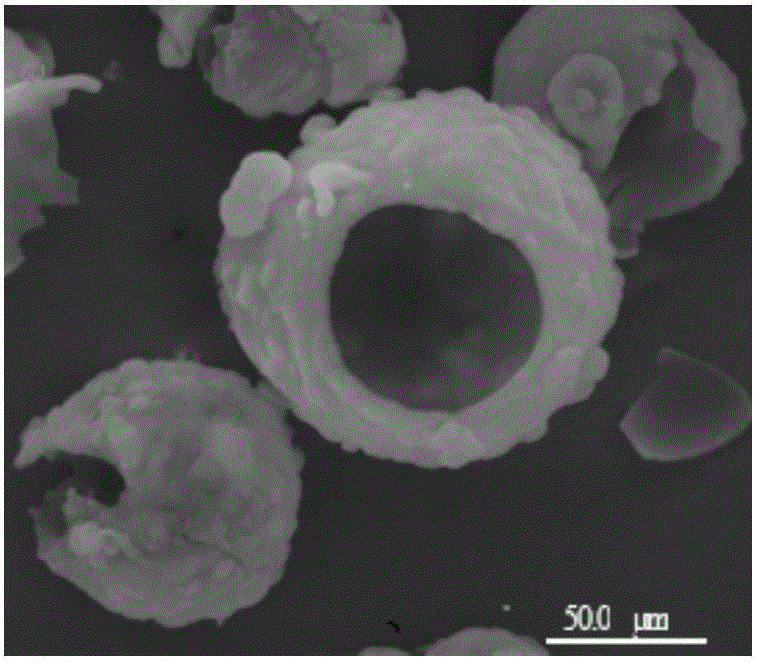

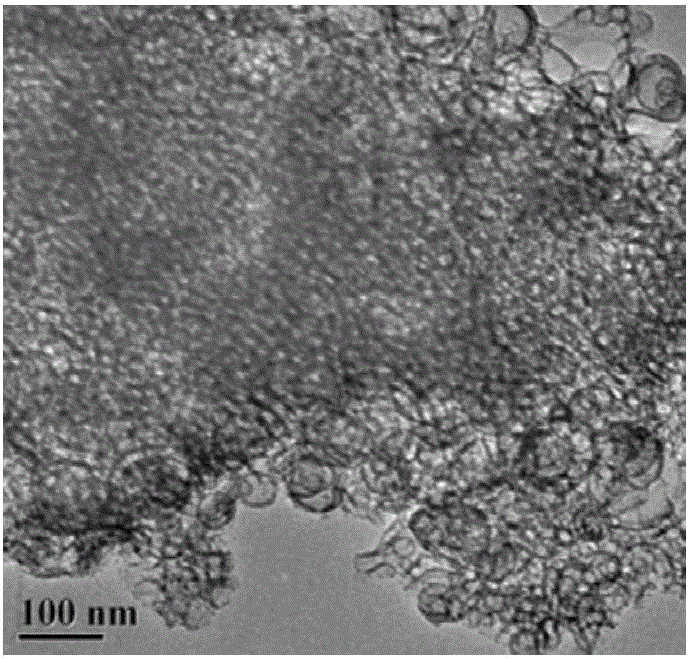

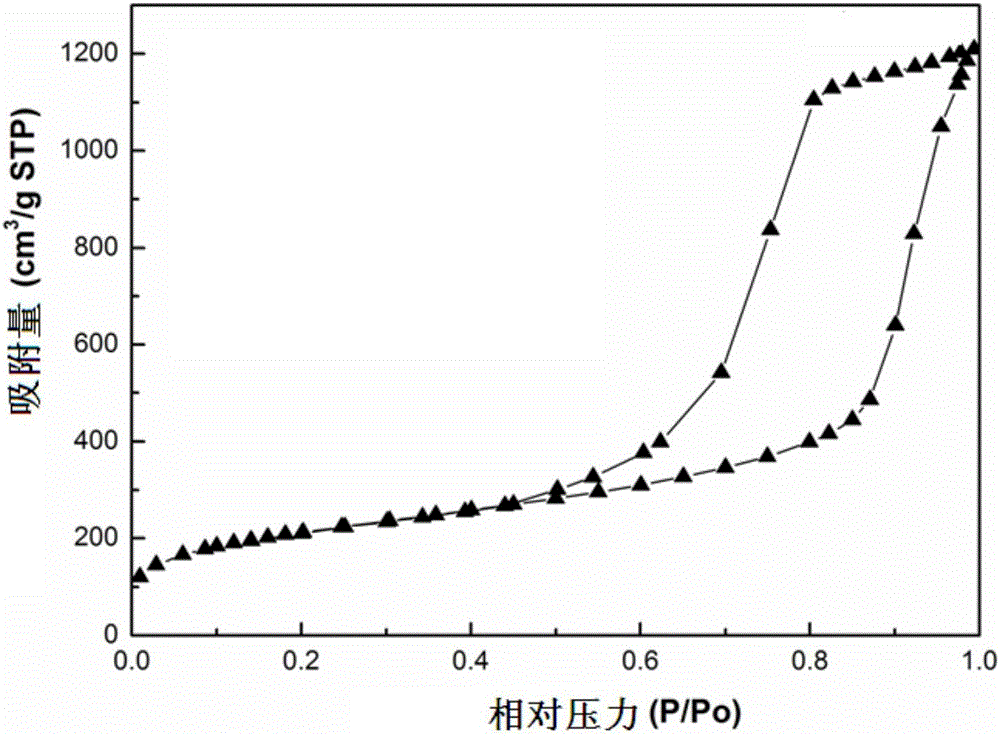

[0030] 1. Preparation of hollow spherical mesoporous silica

[0031] Add 1 g of P123 with a number average molecular weight of 5800, 3.7 mL of concentrated HCl (37% by mass), 30 mL of deionized water into a 100 mL beaker, and then add 2.5 g of 1,3,5-trimethylbenzene and 5.0 g of n-decyl alkane, stirred to completely dissolve P123, then added 2g of tetraethyl orthosilicate, reacted with magnetic stirring at 40°C for 20 hours, then transferred to a hydrothermal reaction kettle, reacted with hydrothermal reaction at 100°C for 30 hours, cooled to room temperature, and filtered with suction , fully filtered and washed with deionized water and absolute ethanol, respectively, and then vacuum-dried at 80°C for 10 hours, the resulting product was placed in a muffle furnace and calcined at 550°C for 4 hours, the template agent P123 was removed, and cooled to room temperature to obtain Hollow spherical mesoporous silica.

[0032] 2. Immobilized Chloroperoxidase

[0033] Add 5mg of holl...

Embodiment 2

[0036]In step 1 of Example 1, 1 g of P123 with a number average molecular weight of 5800, 3.7 mL of concentrated HCl (37% by mass), 30 mL of deionized water were added to a 100 mL beaker, and then 1.5 g of 1,3,5- Trimethylbenzene and 6g of n-decane were stirred to completely dissolve P123, then 2g of tetraethyl orthosilicate was added, and the reaction was carried out under magnetic stirring at 40°C for 20 hours, then transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 100°C for 30 hour, cooled to room temperature, suction filtered, fully filtered and washed with deionized water and absolute ethanol respectively, and then vacuum-dried at 80°C for 10 hours, and the resulting product was calcined in a muffle furnace at 550°C for 4 hours to remove the template Agent P123, cooled to room temperature to obtain hollow spherical mesoporous silica. The other steps were the same as in Example 1 to obtain a hollow spherical mesoporous silica / chloroperoxidase nan...

Embodiment 3

[0038] In step 1 of Example 1, 1.5 g of P123 with a number average molecular weight of 5800, 3.7 mL of concentrated HCl (37% by mass), 30 mL of deionized water were added to a 100 mL beaker, and then 3 g of 1,3,5- Trimethylbenzene and 4.5g of n-decane were stirred to completely dissolve P123, then 2.5g of tetraethyl orthosilicate was added, and the reaction was carried out under magnetic stirring at 40°C for 20 hours, then transferred to a hydrothermal reaction kettle, and hydrothermally heated at 100°C React for 30 hours, cool to room temperature, filter with suction, fully filter and wash with deionized water and absolute ethanol respectively, then vacuum dry at 80°C for 10 hours, and place the product in a muffle furnace for calcination at 550°C for 4 hours. The template agent P123 was removed, and cooled to room temperature to obtain hollow spherical mesoporous silica. The other steps are the same as in Example 1, and the hollow spherical mesoporous silica / chloroperoxidase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com