Polystyrene/polyethylene blended high-flame-resistance extruded sheet and production method thereof

A technology of polystyrene and polyethylene, which is applied in the field of high flame-retardant extruded plastic board and its preparation, can solve the problems that white pollution sources cannot be self-degraded, the flame-retardant effect cannot be achieved, and the product performance is poor, so as to improve hardness and improve Insulation effect, effect of improving product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

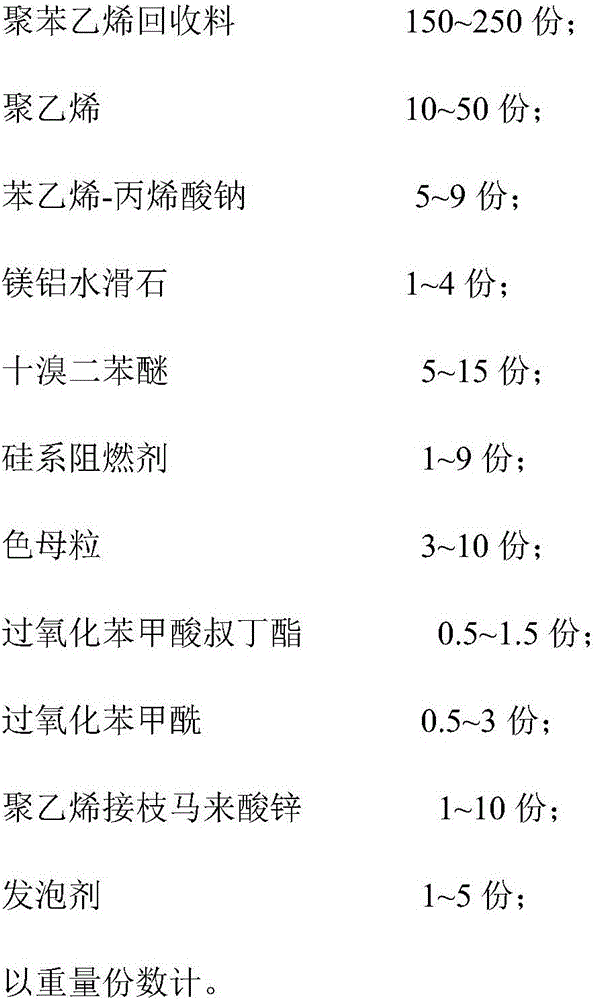

[0023] Example 1: A polystyrene / polyethylene blended polystyrene / polyethylene blended high flame-retardant extruded board includes the following components:

[0024]

[0025]

[0026] The carrier of the color masterbatch is polyperfluoroethylene propylene.

[0027] The preparation method of the above-mentioned polystyrene / polyethylene blended high flame-retardant extruded board comprises the following steps:

[0028] (1) Add the decolorized polystyrene recycled material into the mixer, heat it to 185°C under the condition of nitrogen, add benzoyl butyl peroxide and benzoyl peroxide, mix well and keep stirring Stop stirring after 3h and cool to 60°C;

[0029] (2) Add new polystyrene material, polyethylene, color masterbatch and polyethylene grafted zinc maleate to the system in step (1), heat to 230°C again under nitrogen, mix uniformly and Keep stirring for 1.5 hours, add decabromodiphenyl ether, silicon-based flame retardant, styrene-sodium acrylate and magnesium alum...

Embodiment 2

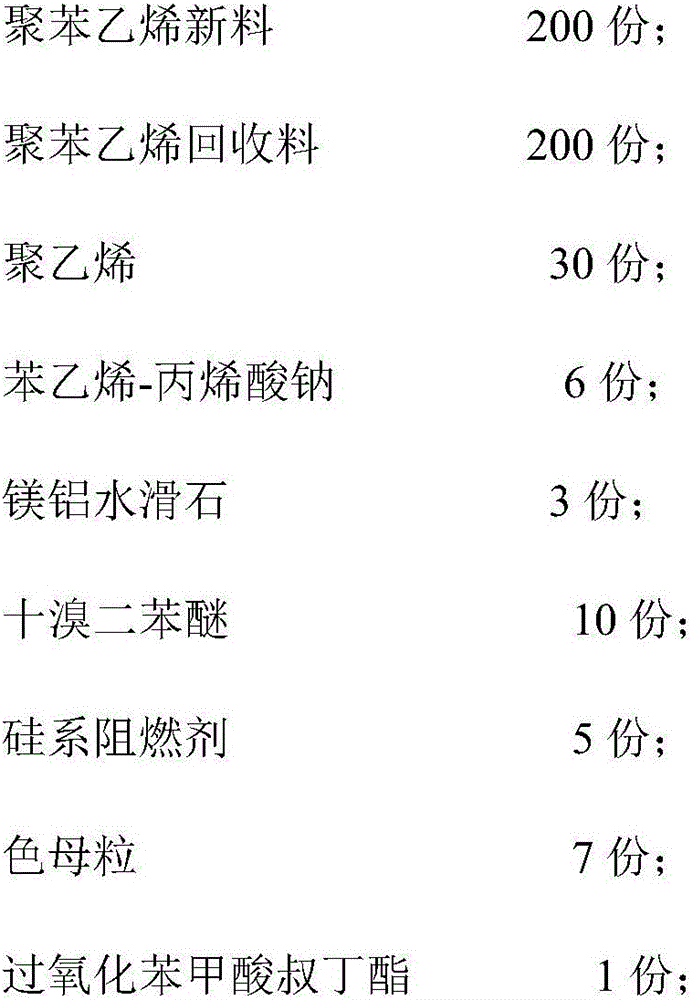

[0032] Example 2: Polystyrene / polyethylene blended polystyrene / polyethylene blended high flame-retardant extruded board includes the following components:

[0033]

[0034] The carrier of the color masterbatch is polyperfluoroethylene propylene.

[0035] The preparation method of the above-mentioned polystyrene / polyethylene blended high flame-retardant extruded board comprises the following steps:

[0036] (1) Add the decolorized polystyrene recycled material into the mixer, heat it to 150°C under nitrogen, add benzoyl butyl peroxide and benzoyl peroxide, mix well and keep stirring Stop stirring after 2h and cool to 50°C;

[0037] (2) Add polystyrene new material, polyethylene, color masterbatch and polyethylene grafted zinc maleate to the system in step (1), heat to 180°C again under nitrogen, mix uniformly and Keep stirring for 1 hour, add decabromodiphenyl ether, silicon-based flame retardant, styrene-sodium acrylate and magnesium aluminum hydrotalcite and continue sti...

Embodiment 3

[0040] Example 3: Polystyrene / polyethylene blended polystyrene / polyethylene blended high flame-retardant extruded board includes the following components:

[0041]

[0042]

[0043] The carrier of the color masterbatch is polyperfluoroethylene propylene.

[0044] The preparation method of the above-mentioned polystyrene / polyethylene blended high flame-retardant extruded board comprises the following steps:

[0045] (1) Add the decolorized polystyrene recycled material into the mixer, heat to 200°C under nitrogen, add butyl benzoyl peroxide and benzoyl peroxide, mix well and keep stirring Stop stirring after 5h and cool to 80°C;

[0046] (2) Add polystyrene new material, polyethylene, color masterbatch and polyethylene grafted zinc maleate to the system in step (1), and heat to 250°C again under the condition of nitrogen flow, mix uniformly and Insulate and stir for 2 hours, add decabromodiphenyl ether, silicon-based flame retardant, styrene-sodium acrylate and magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com