A kind of high damping chlorobutyl damping rubber and preparation method thereof

A chlorinated butyl and damping rubber technology, applied in the field of damping materials, can solve the problems of effective damping temperature range, damping performance and mechanical properties can not meet actual needs, etc., achieve easy large-scale production, economical and practical preparation process, damping Excellent performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

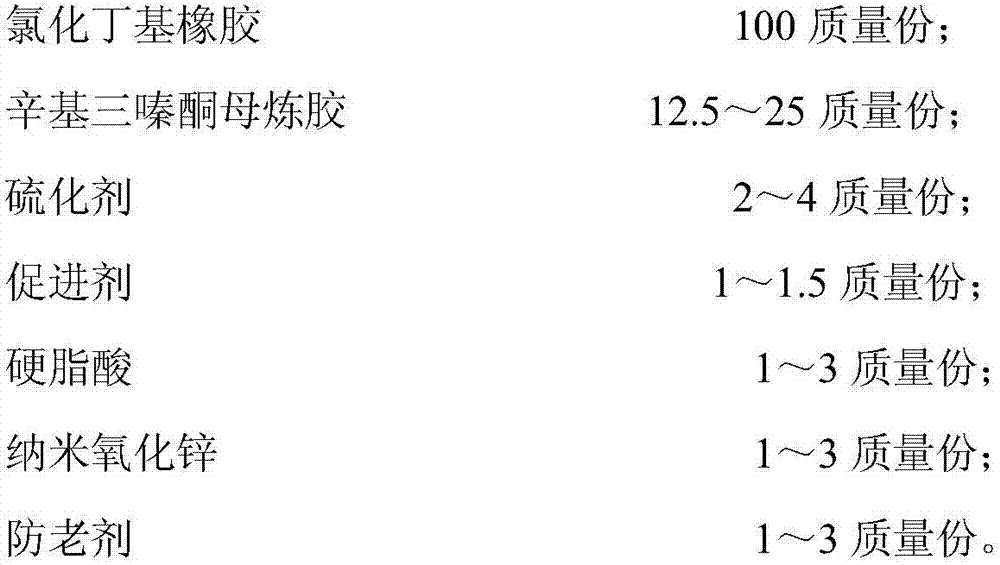

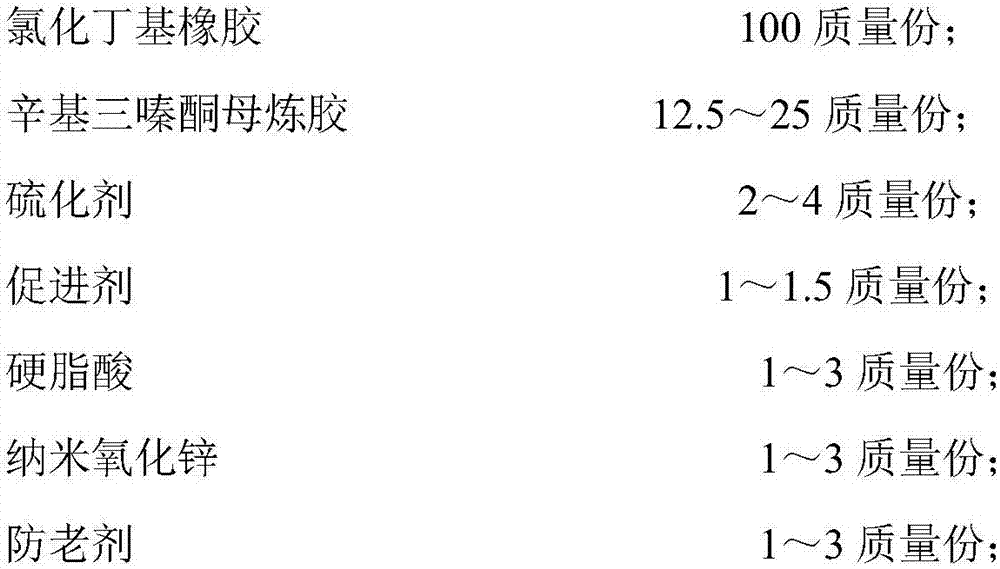

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of octyl triazone masterbatch: put 100g chlorobutyl rubber and 80g octyl triazone into an open mill, and mix for 40min at a roller temperature of 30°C to obtain octyl triazone Base triazone masterbatch, spare.

[0028] 2. Preparation of high damping chlorobutyl damping rubber:

[0029] a) Put 100g of chlorobutyl rubber, 1g of accelerator TMTD, 1g of stearic acid, 1g of nano-zinc oxide, and 1g of anti-aging agent D into the open mill in turn, and knead for 20min at a roller temperature of 20°C ;

[0030] b) Adjust the roll distance of the open mill to 1mm first, then add 12.5g of octyltriazone masterbatch, pound the rubber, and mix for 5min; then adjust the roll distance of the open mill to 3mm, and continue to mix for 20min until Form a smooth and gap-free adhesive layer;

[0031] c) extruding the rubber material roller after kneading into the sheet, allowing the obtained film to cool down to room temperature naturally, for subsequent use;

[0032] d)...

Embodiment 2

[0038] 1. Preparation of octyl triazone masterbatch: put 100g chlorobutyl rubber and 80g octyl triazone into an open mill, and mix for 35min at a roller temperature of 40°C to obtain octyl triazone Base triazone masterbatch, spare.

[0039] 2. Preparation of high damping chlorobutyl damping rubber:

[0040] a) Put 100g of chlorobutyl rubber, 1.2g of accelerator TMTD, 2g of stearic acid, 2g of nano-zinc oxide, and 2g of anti-aging agent D into the open mill in turn, and knead under the condition that the roller temperature is 35°C 25min;

[0041] b) Adjust the roll distance of the open mill to 1.5mm first, then add 20g of octyltriazone masterbatch, pound the rubber, and mix for 10min; then adjust the roll distance of the open mill to 4mm, and continue to mix for 25min until Form a smooth and gap-free adhesive layer;

[0042] c) extruding the rubber material roller after kneading into the sheet, allowing the obtained film to cool down to room temperature naturally, for subseq...

Embodiment 3

[0049] 1. Preparation of octyl triazone masterbatch: put 100g chlorobutyl rubber and 80g octyl triazone into the open mill, and mix for 30min at a roller temperature of 50°C to obtain octyl triazone Base triazone masterbatch, spare.

[0050] 2. Preparation of high damping chlorobutyl damping rubber:

[0051] a) Put 100g of chlorobutyl rubber, 1.5g of accelerator TMTD, 3g of stearic acid, 3g of nano-zinc oxide, and 3g of anti-aging agent D into the open mill in turn, and knead under the condition that the roller temperature is 50°C 30min;

[0052]b) Adjust the roller distance of the open mill to 2mm first, then add 25g of octyltriazone masterbatch, pound the rubber, and mix for 15 minutes; then adjust the roller distance of the open mill to 5mm, and continue to mix for 30 minutes until the mixture is formed Smooth and gap-free adhesive layer;

[0053] c) extruding the rubber material roller after kneading into the sheet, allowing the obtained film to cool down to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com