A kind of phosphorus tailings/polypropylene composite material and preparation method thereof

A technology for composite materials and phosphorus tailings, applied in the field of phosphorus tailings/polypropylene composite materials and their preparation, can solve the problems of insufficient heat resistance, short service life, etc., so as to reduce usage, reduce production costs, and control strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

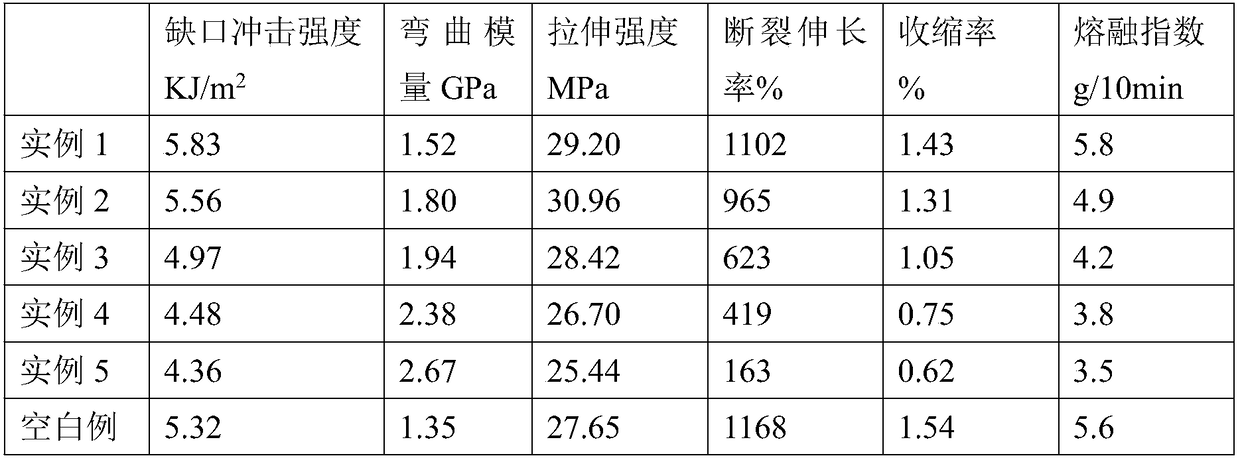

Examples

preparation example Construction

[0027] The preparation process of composite material of the present invention:

[0028] Dry the phosphorous tailings in a drying oven;

[0029] The dried phosphorus tailings and polypropylene are premixed according to the formula ratio, so that the raw materials are preliminarily mixed uniformly to obtain a premix, wherein the formula ratio is counted by weight percentage, the polypropylene is 50% to 90%, and the phosphorus tailings 10% to 50%.

[0030] Put the premix into the twin-screw extruder for mixing, wherein: the twin-screw extruder is parallel twin-screw in the same phase, the length-to-diameter ratio is 32:1-48:1; the speed is 160-250r / min ; Processing temperature is 165 ~ 190 ℃.

Embodiment 1

[0036] Composition of raw materials: 95% by mass of polypropylene and 5% of phosphorous tailings.

[0037] The twin-screw extruder used is 25cm in diameter, the aspect ratio is 32:1, the speed is 210r / min, the processing temperature is 165°C in the first zone, 170°C in the second zone, 175°C in the third zone, 180°C in the fourth zone, and 170°C ℃.

[0038] The phosphorous tailings / polypropylene composite material of this example was prepared according to the above preparation method.

Embodiment 2

[0040] Composition of raw materials: 90% by mass of polypropylene and 10% of phosphorous tailings.

[0041] The twin-screw extruder used is 25cm in diameter, the aspect ratio is 32:1, the speed is 210r / min, the processing temperature is 170°C in the first zone, 175°C in the second zone, 180°C in the third zone, 185°C in the fourth zone, and 175°C in the head. ℃.

[0042] The phosphorous tailings / polypropylene composite material of this example was prepared according to the above preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com